Method for preparing graphene/ferroferric oxide composite microspheres

A technology of ferroferric oxide and graphene, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as low production efficiency, complicated operation process, and long time, and achieve Easy to operate, wide application prospects, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A Graphene / Fe 3 o 4 A preparation method for composite microspheres, comprising the steps of:

[0023] (1) Weigh 0.005 mol ferric nitrate and 0.005 mol citric acid in sequence, add them to 100 mL deionized water, and stir to obtain a clear solution.

[0024] (2) Weigh 0.3 g of graphene oxide, add it to the solution obtained in (1), and sonicate until it is uniformly dispersed, and the concentration of graphene oxide in the solution is 3 g / L.

[0025] (3) Add the mixed liquid obtained in (2) to the atomization device to form mist droplets, and bring it into a tube furnace with a furnace temperature of 800 °C with nitrogen gas, and collect black Graphene / Fe after reaction 3 o 4 Composite microspheres.

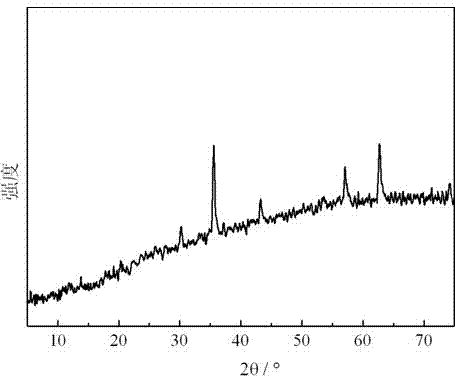

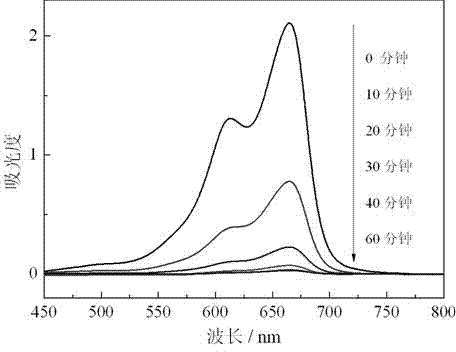

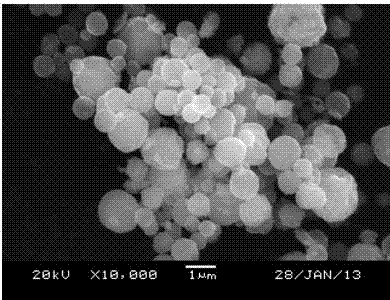

[0026] figure 1 In, the X-ray diffraction pattern of the obtained sample is consistent with that of Fe 3 o 4 The peaks on the standard PDF card are consistent. It shows that what is obtained is Graphene / Fe 3 o 4 Composite microspheres. Depend on figure 2 It ca...

Embodiment 2

[0028] A Graphene / Fe 3 o 4 A preparation method for composite microspheres, comprising the steps of:

[0029] (1) Weigh 0.002 mol ferric nitrate and 0.003 mol citric acid in sequence, add them to 200 mL deionized water, and stir to obtain a clear solution.

[0030] (2) Measure 0.2 g of graphene oxide, add it to the solution obtained in (1), and sonicate until it is uniformly dispersed, and the concentration of graphene oxide in the solution is 1 g / L.

[0031] (3) Add the mixed liquid obtained in (2) to the atomization device to form mist droplets, and bring it into a tube furnace with a furnace temperature of 600 °C with argon gas, and collect black Graphene / Fe after reaction 3 o 4 Composite microspheres.

Embodiment 3

[0033] A Graphene / Fe 3 o 4 A preparation method for composite microspheres, comprising the steps of:

[0034] (1) Weigh 0.01 mol ferric nitrate and 0.03 mol urea in sequence, add them to 100 mL deionized water, and stir to obtain a clear solution.

[0035] (2) Measure 0.6 g of graphene oxide, add it to the solution obtained in (1), and sonicate until it is uniformly dispersed, and the concentration of graphene oxide in the solution is 6 g / L.

[0036] (3) Add the mixed liquid obtained in (2) to the atomization device to form mist droplets, and bring it into a tube furnace with a furnace temperature of 900 °C with argon gas, and collect black Graphene / Fe after reaction 3 o 4 Composite microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com