Preparation method of open tubular capillary electrochromatographic column

A capillary electrochromatography, capillary technology, applied in the field of chromatography, can solve the problems of difficult chromatographic separation, lack of chemically reactive groups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

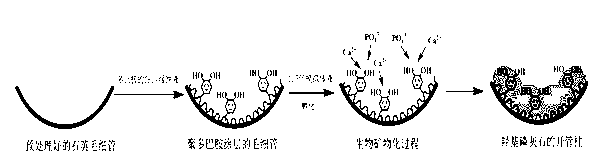

Image

Examples

Embodiment 1

[0020] Cut off a 60cm long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse with 1M NaOH for 2 hours, H 2 Rinse with O for half an hour, blow dry with nitrogen; weigh 10 mg of dopamine and dissolve in 5 mL of 10 mM Tris buffer, adjust the pH to 8.5, shake the prepared dopamine solution for 5 minutes, and then continuously inject it at a flow rate of 0.01 mL / min Put the pretreated capillary in water for 20 hours, wash with water, and blow dry with nitrogen to obtain a capillary whose inner wall is modified with a polydopamine coating; repeat the polydopamine modification step to obtain a capillary whose inner wall is modified with a multi-layer polydopamine coating. Then pass 1.5 times of simulated body fluid into the above-mentioned capillary tube containing multi-layer polydopamine coating, seal both ends of the capillary tube, put it in a 37°C water bath for incubation for 14 days, take it out, wash it with water, and obtain an open-tube capillary column of hydroxyapatite ...

Embodiment 2

[0023] Cut off a 60cm long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse with 1M NaOH for 2 hours, H 2 Rinse with O for half an hour, blow dry with nitrogen; weigh 10 mg of dopamine and dissolve in 5 mL of 10 mM Tris buffer, adjust the pH value to 8.5, shake the prepared dopamine solution for 5 minutes, and pass it into the pre- Put the treated capillary in water for 20 hours, wash with water, blow dry with nitrogen, and obtain a capillary with polydopamine coating on the inner wall; pass 1.5 times simulated body fluid into the above capillary containing polydopamine coating, seal both ends of the capillary, and put After incubating in a water bath at 37° C. for 14 days, it was taken out and washed with water to obtain an open-tube capillary column of hydroxyapatite.

Embodiment 3

[0025] Cut off a 60cm long quartz capillary (50 μm i.d. × 375 μm o.d.), rinse with 1M NaOH for 2 hours, H 2 Rinse with O for half an hour, blow dry with nitrogen; weigh 10 mg of dopamine and dissolve in 5 mL of 10 mM Tris buffer, adjust the pH to 8.5, shake the prepared dopamine solution for 5 minutes, and then continuously inject it at a flow rate of 0.01 mL / min Put the pretreated capillary in water for 20 hours, wash with water, and blow dry with nitrogen to obtain a capillary whose inner wall is modified with a polydopamine coating; repeat the polydopamine modification step to obtain a capillary whose inner wall is modified with a multi-layer polydopamine coating. Then pass 1.5 times of simulated body fluid into the above-mentioned capillary containing multi-layer polydopamine coating, seal both ends of the capillary, put it in a 37°C water bath for incubation for 7 days, take it out, wash it with water, and obtain an open-tube capillary column of hydroxyapatite .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com