Au-Pd bimetallic catalyst for preparing methyl formate by selective oxidation of methanol as well as preparation method and application thereof

A technology of bimetallic catalysts and methyl formate, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low conversion rate and high reaction temperature, Achieve the effect of high selectivity, good catalytic activity and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

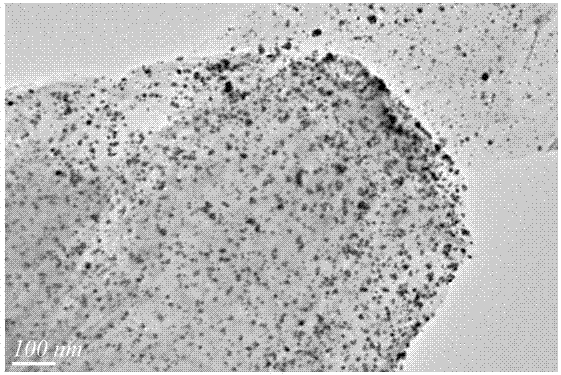

Image

Examples

Embodiment 1

[0041] (1) 1g of graphene carrier (specific surface area 120m 2 / g, C / O molar ratio 6, conductivity 15S / cm) into 20ml of water, heated to 60oC and stirred evenly. Add 2g of NaOH therein, the pH must be controlled at 14, and continue to stir for 0.5h.

[0042] (2) Add 5ml HAuCl containing Au0.0025g 4 solution and 20ml PdCl containing Pd0.01g 2 Mix the solution and stir well.

[0043] (3) Add the prepared solution in (2) to (1) drop by drop under constant stirring, and continue to stir for 2 hours after the dropwise addition is completed.

[0044] (4) Pump and wash the precipitate of (3) with deionized water until there is no Cl - , dried at 110°C for 15h, and calcined at 200°C for 5h in a nitrogen atmosphere to prepare the catalyst Au 0.25 PD 1.0 / Graphene.

[0045] After the catalyst was activated on-line at 150°C in a fixed bed for 1 hour in an air atmosphere, CH 3 OH / O 2 Molar ratio 1:5, reaction space velocity 3000ml·g -1 h -1 , 50 ° C reaction. The conversion r...

Embodiment 2

[0047] (1) 1g of graphene carrier (specific surface area 100m 2 / g, C / O molar ratio 8, conductivity 30S / cm) was added to 20ml of water, heated to 70°C and stirred evenly. After adding 1g of KOH therein, the pH must be controlled at 13, and the stirring was continued for 1h.

[0048] (2) Add 15ml HAuCl containing Au0.01g 4 solution and 20ml PdCl containing Pd0.01g 2 Mix the solution and stir well.

[0049] (3) Add the prepared solution in (2) to (1) drop by drop under constant stirring, and continue to stir for 1 hour after the dropwise addition is completed.

[0050] (4) Pump and wash the precipitate of (3) with deionized water until there is no Cl - , dried at 110°C for 13h, and calcined at 200°C for 4h in a nitrogen atmosphere to prepare the catalyst Au 1.0 PD 1.0 / Graphene.

[0051] After the catalyst was activated online at 160°C in a fixed bed for 1.5h in an air atmosphere, CH 3 OH / O 2 Molar ratio 1:3, reaction space velocity 10000ml·g -1 h -1 , 90 ° C reaction...

Embodiment 3

[0053] (1) 1g of graphene carrier (specific surface area 150m 2 / g, C / O molar ratio 8, conductivity 10S / cm) was added to 20ml of water, heated to 60°C and stirred evenly. After adding 2g KOH therein, the pH must be controlled at 13, and the stirring was continued for 2h.

[0054] (2) Add 15ml HAuCl containing Au0.01g 4 solution and 40ml Pd(NO 3 ) 2 Mix the solution and stir well.

[0055] (3) Add the solution prepared in (2) to (1) drop by drop under continuous stirring. After the dropwise addition, the pH value needs to be controlled at 12, and continue to stir for 1 hour.

[0056] (4) Pump and wash the precipitate of (3) with deionized water until there is no Cl - , Dry at 110°C for 20h, and bake at 250°C for 4h in a nitrogen atmosphere. Catalyst Au 1.0 PD 2.0 / Graphene.

[0057] After the catalyst was activated on-line at 180°C in a fixed bed for 1.0 h in an air atmosphere, CH 3 OH / O 2 Molar ratio 1:5, reaction space velocity 15000ml·g -1 h -1 , 70 ° C reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com