Overwintering thermal sleeve for grape vine and overwintering thermal treatment method for grape vine

A treatment method and grapevine technology, which is applied in the field of grapevine overwintering warm cover and overwintering warming treatment, can solve the problems of not being able to better keep warm, difficult to tie together, and heavy labor, so as to achieve environmental protection and practical warmth Good heat preservation effect and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

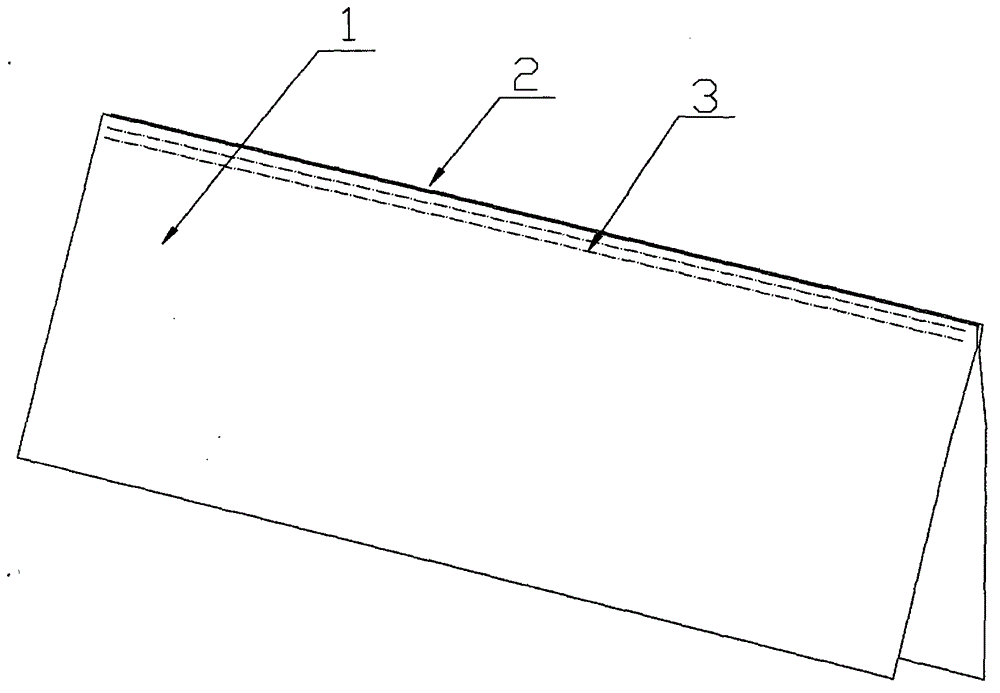

[0041] like figure 1 As shown, a kind of vine overwintering warm cover is characterized in that it comprises two thermal insulation blankets 1 arranged in pairs, and the thermal insulation blanket 1 includes an upper edge 2, and the upper edges of the two thermal insulation blankets can be connected to each other through a connection structure. The connection is disassembled, and the remaining edges are free edges.

[0042] The thermal insulation blanket 1 is a polymer fiber composite thermal insulation material.

[0043] The polymer fiber composite thermal insulation material comprises a composite thermal insulation layer, polyethylene film and non-woven fiber layer.

[0044] The polymer fiber composite thermal insulation material is PE casting film-coated non-woven fabric.

[0045] The thermal insulation blanket 1 is rectangular, and its width is 500-1500 mm.

[0046] The connection structure is a Velcro 3 .

Embodiment 2

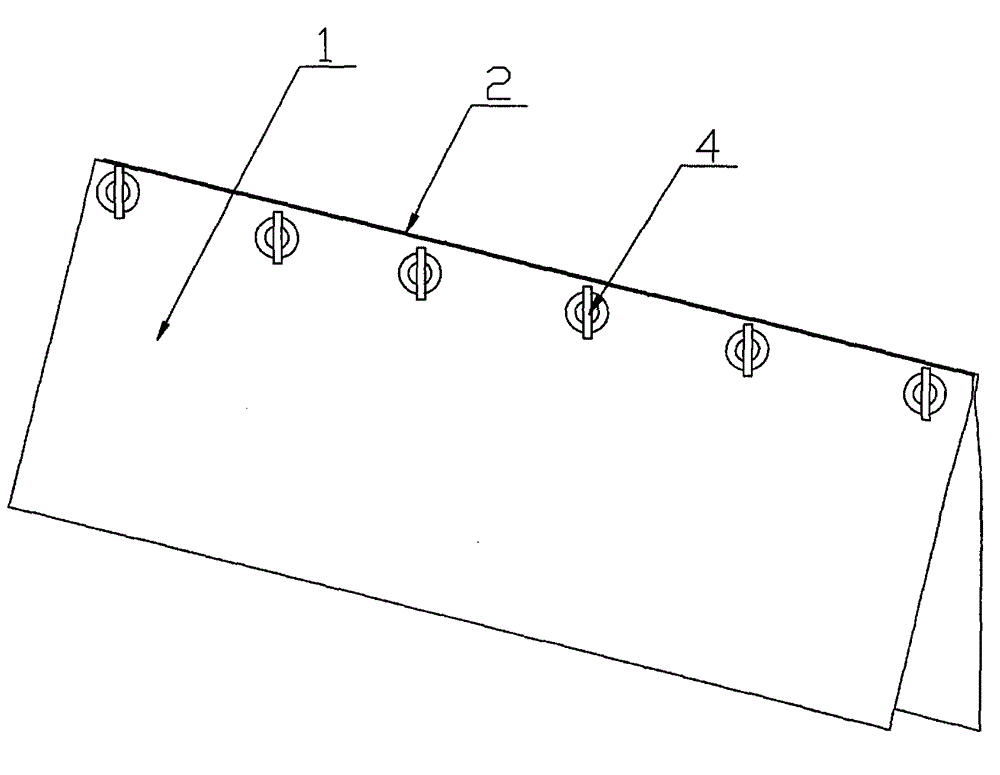

[0048] like figure 2 Shown, a kind of vine overwintering thermal cover, it differs from embodiment 1 in that the connecting structure is a lock 4.

Embodiment 3

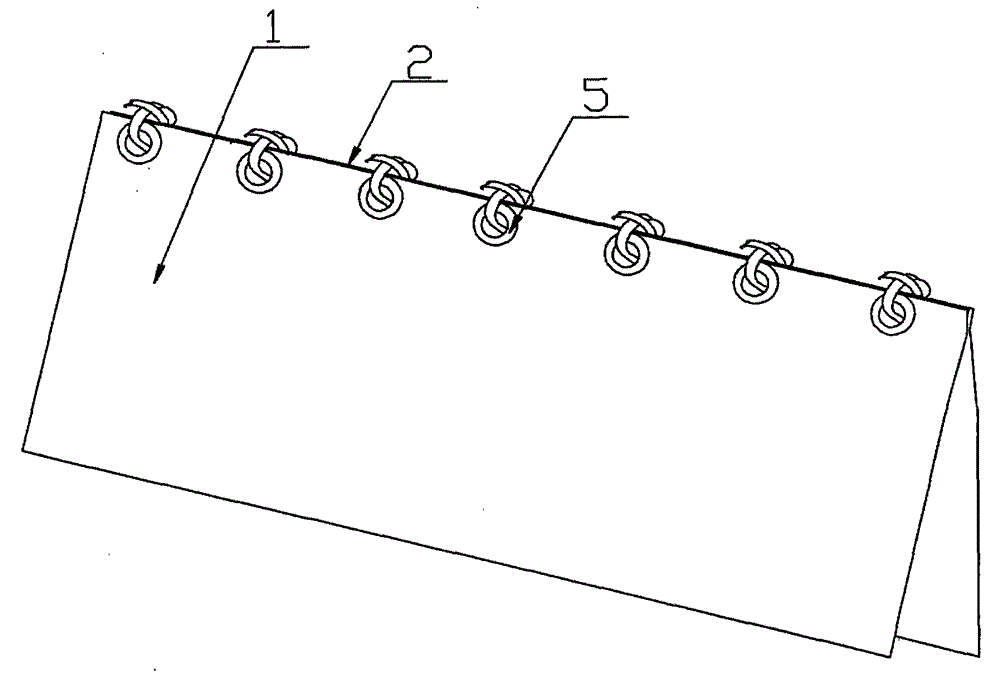

[0050] like image 3 As shown, a grapevine overwintering warm cover, which is different from Example 1 in that the connection structure includes air holes 5 and laces evenly distributed on the upper edge of the thermal insulation blanket, and the laces connect the two thermal insulation blankets 1 The air eyes 5 at the upper corresponding positions are connected together.

[0051] like Figure 4 to Figure 5 As shown, a grapevine overwintering warming treatment method includes standing stakes 7 evenly distributed in the grape field and tie wires 8 arranged in parallel between the standing stakes 7, and is characterized in that it also includes the use of the grape Rattan overwintering warm jacket, the processing steps are as follows:

[0052] 1), straddle the top of the vine overwintering warm cover on the lead binding wire 8, and connect the upper edge 2 of the thermal insulation blanket firmly through the connection structure; the connection structure can be selected from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com