Oral film-form base and preparation

一种口腔内、薄膜状的技术,应用在口腔内薄膜状基剂及制剂领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

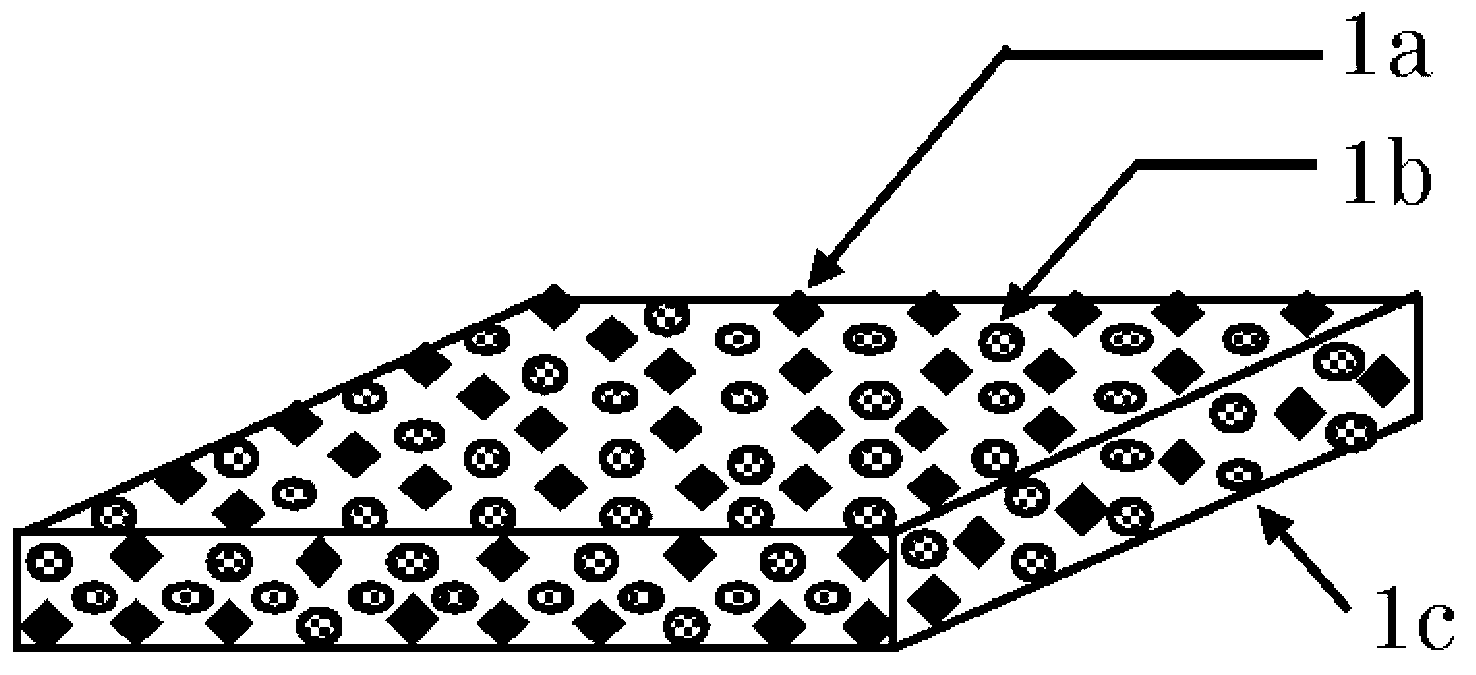

Image

Examples

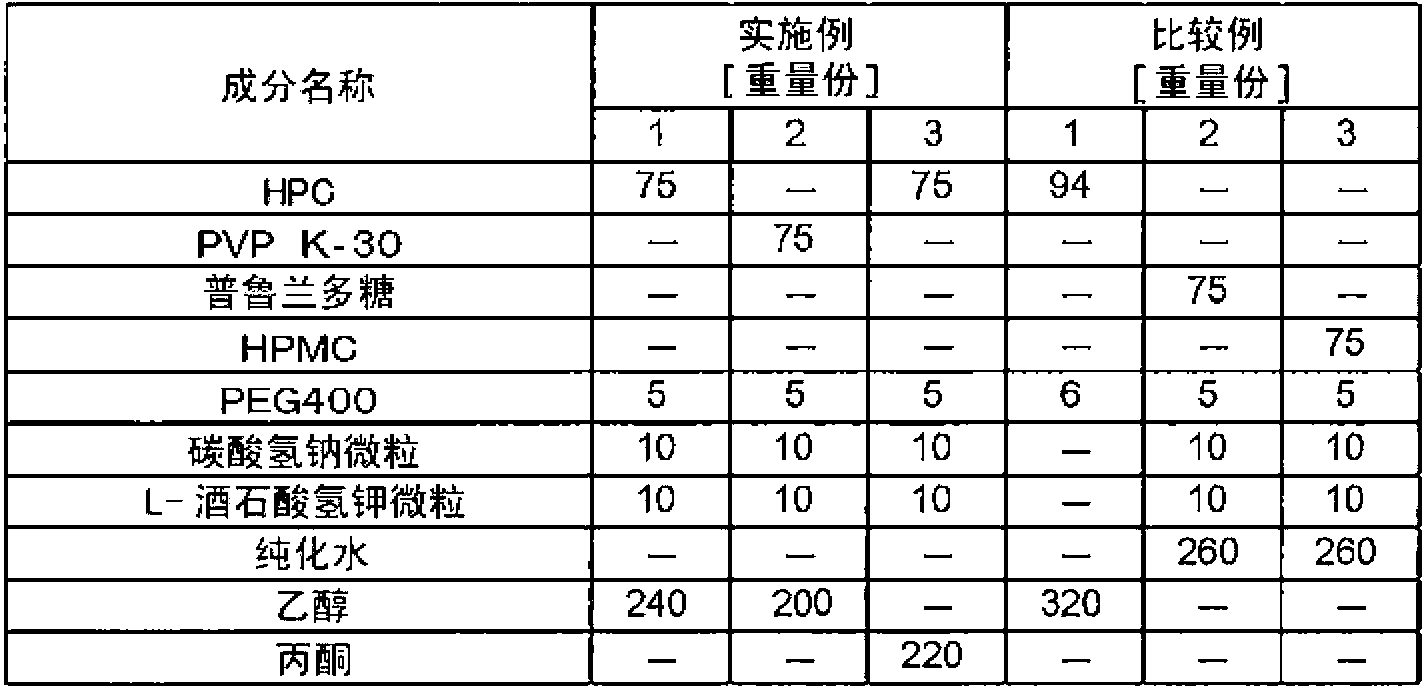

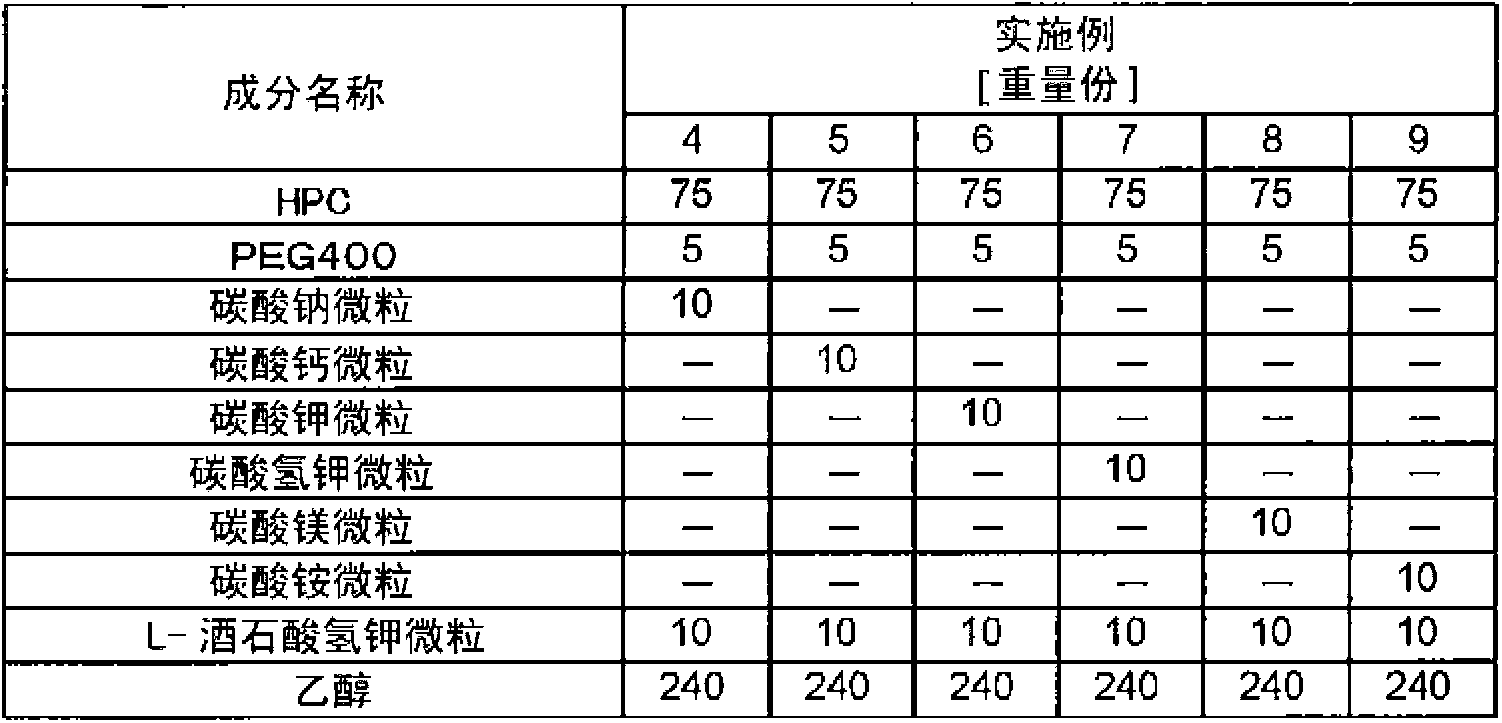

Embodiment 1

[0122] Add 5 parts by weight of polyethylene glycol (PEG400) to 240 parts by weight of ethanol, 10 parts by weight of sodium bicarbonate microparticles (manufactured by Wako Pure Chemical Industry Co., Ltd.) of previously controlled particle size, and L-potassium hydrogen tartrate microparticles (manufactured by Komatsuya Co., Ltd. ) 10 parts by weight, which is beneficial to ultrasonic waves to disperse them more fully, then add about 30,000 molecular weight, 53.4 to 77.5% HPC (manufactured by Nippon Soda Corporation, trade name: Nisso HPC SSL) 75 The parts by weight were stirred and dissolved by a rolling mixer to prepare a dispersion. The dispersion liquid was fully defoamed, and then spread and dried on a polyester release film to obtain a film with a thickness of about 70 μm.

[0123] The resulting film was peeled off from the polyester release film and cut into 4 cm 2 rectangle, the oral film-form base of Example 1 was obtained.

Embodiment 2

[0125] Except using PVP with a molecular weight of 1.05 million to 1.2 million (manufactured by Wako Pure Chemical Industries, Ltd., reagent name: POLYVINYLPYRROLIDONE K90) instead of HPC, and following the composition shown in Table 3, the oral cavity of Example 2 was obtained by the same steps as in Example 1. Inner film-like base.

Embodiment 3

[0127] The oral film-form base of Example 3 was obtained by the same procedure as in Example 1 except that acetone was used instead of ethanol and the composition shown in Table 3 was followed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com