Bone repair material and preparation method thereof

A technology for bone repair and calcium sulfate hemihydrate, applied in the field of medical biomaterials, can solve the problems of weak osteogenic activity of calcium sulfate, only has osteoconductivity, lack of osteoinductivity, etc., and achieves accelerated osteogenesis time and efficient induction of the body. The effect of osteogenic and good osteoinductive activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

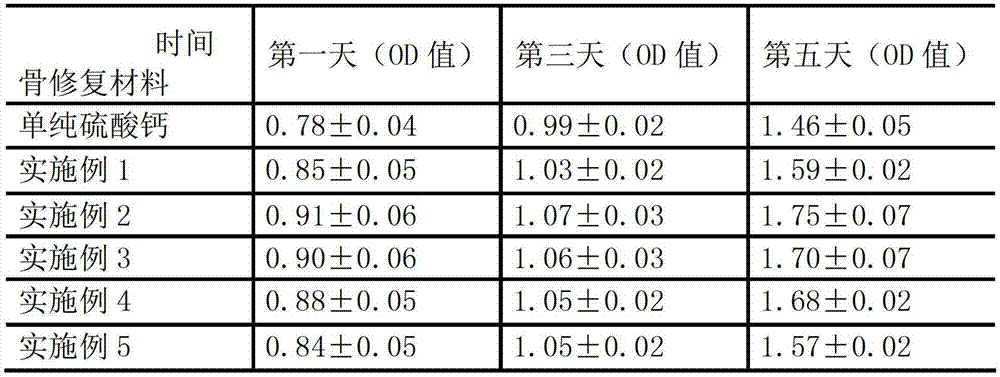

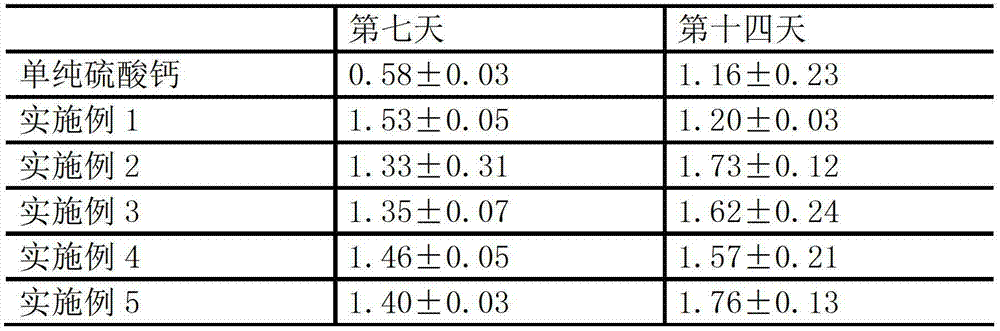

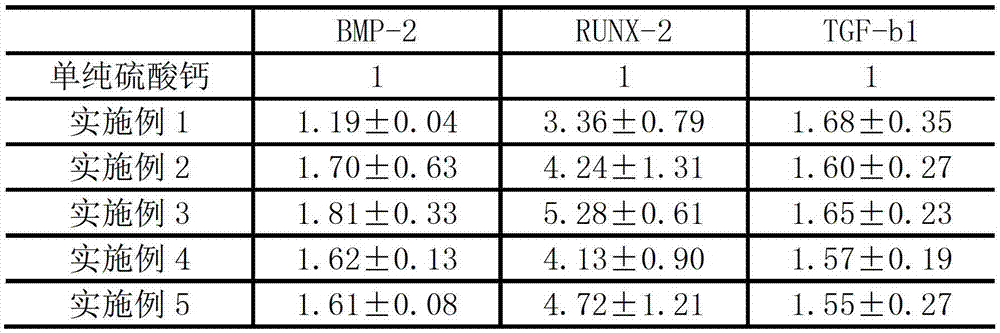

Examples

Embodiment 1

[0026] A bone repair material, which is prepared by mixing calcium sulfate hemihydrate and lugua polypeptide injection in a weight ratio of 90:30, and then preparing through the following steps:

[0027] (1) Mix the quantitative calcium sulfate hemihydrate and Lugua polypeptide injection in a ratio of 90:30, and stir well until the calcium sulfate hemihydrate is evenly distributed in the Lugua polypeptide injection, and the mixture is gel-like. If it is simply mixed, but it is not stirred to a gel state, it indicates that the stirring is not sufficient, and the result will be that the calcium sulfate hemihydrate is not sufficiently dispersed in the Lugua polypeptide injection, which will eventually lead to uneven osteogenic activity of the bone repair material. thereby reducing the rate of bone formation

[0028] (2) Inject the mixed liquid obtained in the above step (1) into a mold with a diameter of 5 mm, and under the action of 10 MPa pressure, make the mixed liquid in the ...

Embodiment 2

[0034] The difference between Example 2 and Example 1 is that the bone repair material of this example is made of raw materials mixed with calcium sulfate hemihydrate, lugua polypeptide injection and pure water in a weight ratio of 90:15:15. The average length of the calcium sulfate hemihydrate crystals is between 30um, the average width is 25um, and the average aspect ratio is 1.25.

[0035] In the preparation method, step (2) is to make the mixed fluid in the mold into a 3 mm thick sheet material under the action of 10 MPa, and then volatilize it at normal temperature to obtain a cured product.

[0036] The rest of the preparation steps are consistent with Example 1.

Embodiment 3

[0038] The difference between Example 2 and Example 1 is that the bone repair material of this example is made of raw materials mixed with calcium sulfate hemihydrate, lugua polypeptide injection and pure water in a weight ratio of 90:10:15. The average length of the calcium sulfate hemihydrate crystals is between 33um, the average width is 26um, and the average aspect ratio is 1.28.

[0039] In the preparation method, the step (2) is to make the mixed liquid in the mold into a 3 mm thick sheet material under the action of 8 MPa, and then volatilize it at normal temperature to obtain a cured product.

[0040] The rest of the preparation steps are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com