Production method of metal micro-nano structure based on laser interference induced cross-linking reaction

A technology of laser interference and induced cross-linking, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as batch preparation and application of unfavorable metal micro-nanostructures, process, equipment, efficiency or quality. , to achieve the effect of low cost, high sample quality and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

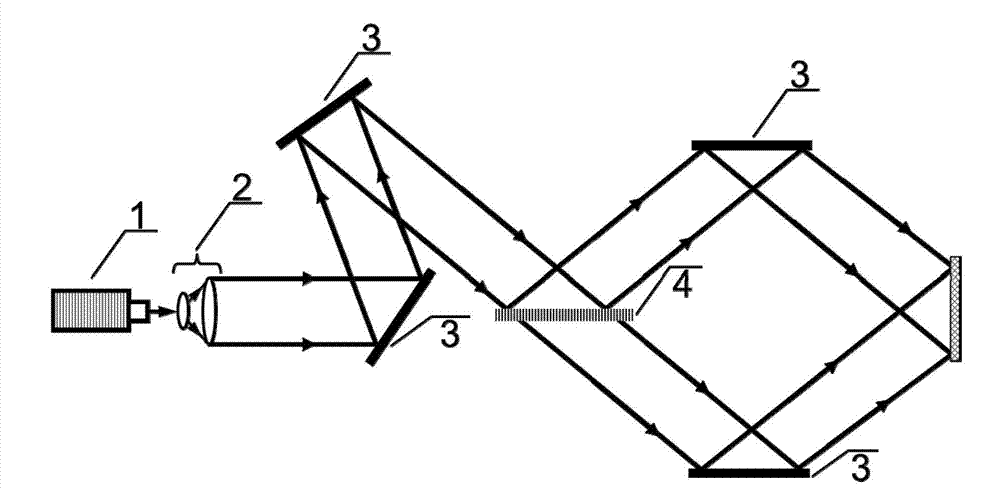

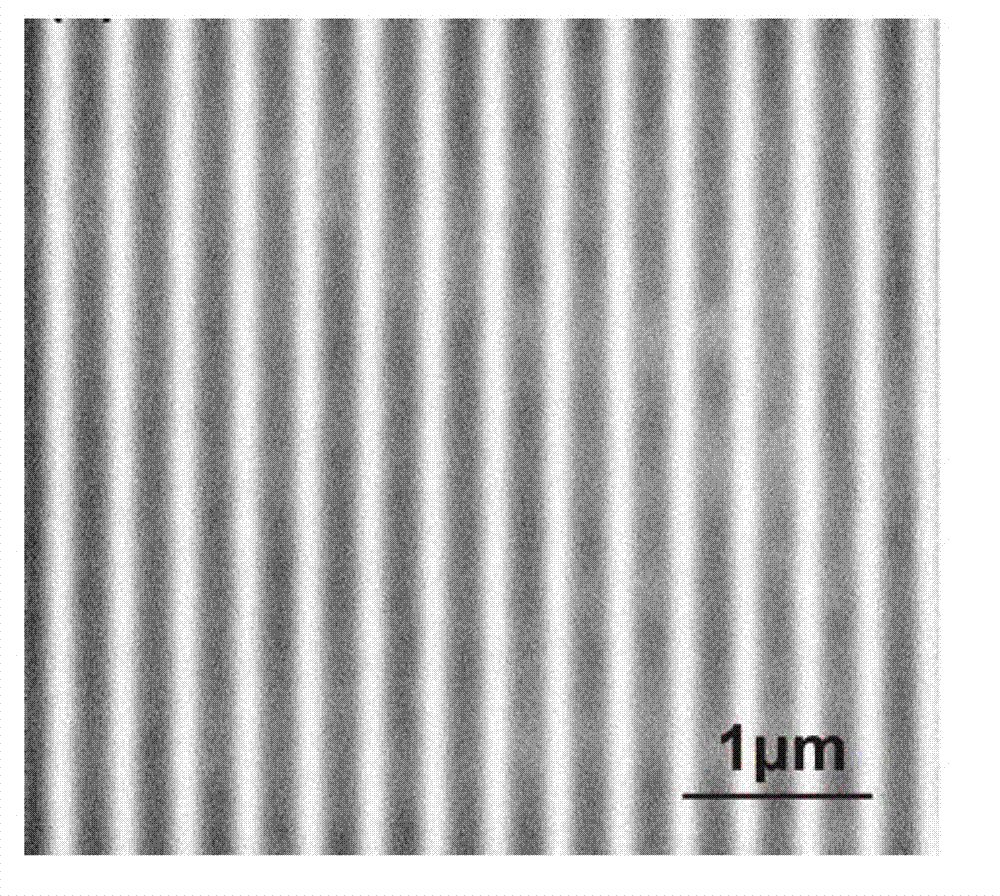

[0019] Example 1: A method for preparing a one-dimensional metal micro-nano structure based on laser interference-induced cross-linking reaction.

[0020] 1) The organic semiconductor material F8BT is dissolved in an organic solvent (the organic solvent is one of xylene, toluene, chlorobenzene, dichlorobenzene, benzene, chloroform, cyclohexane, pentane, hexane or octane ) to make an organic semiconductor solution with a concentration of 25 mg / ml;

[0021] 2) Spin-coat the F8BT solution in step 1) on the substrate at a speed of 2000rpm to prepare an organic semiconductor polymer film with a thickness of 100nm;

[0022] 3) Evaporating a layer of metal film with a thickness of 10nm on the organic semiconductor polymer film in step 2);

[0023] 4) The one-dimensional laser interference light field (laser wavelength is 325nm) interacts with the continuous organic semiconductor polymer film to cause cross-linking reaction of the polymer material and pattern the metal film attached ...

Embodiment 2

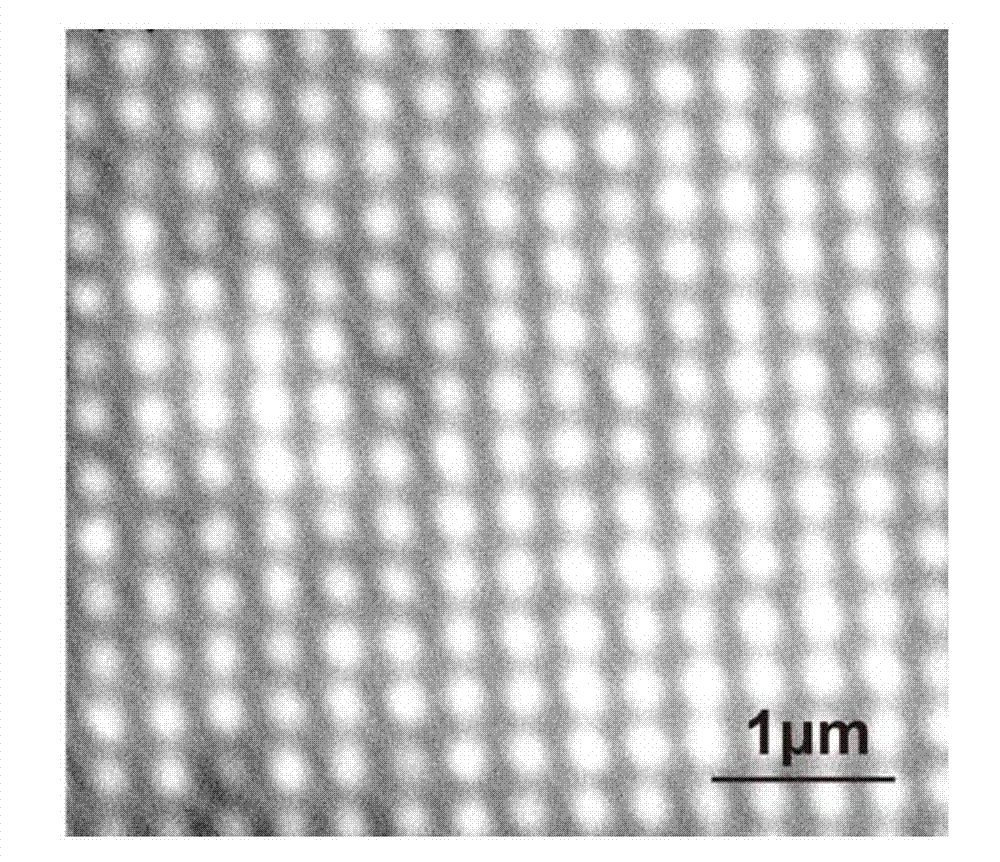

[0024] Example 2: A method for preparing a two-dimensional metal micro-nano structure based on laser interference-induced cross-linking reaction.

[0025] 1) The organic semiconductor material F8BT is dissolved in an organic solvent (the organic solvent is one of xylene, toluene, chlorobenzene, dichlorobenzene, benzene, chloroform, cyclohexane, pentane, hexane or octane ) to make an organic semiconductor solution with a concentration of 25mg / ml;

[0026] 2) Spin-coat the F8BT solution in step 1) on the substrate at a speed of 2000rpm to prepare an organic semiconductor polymer film with a thickness of 100nm;

[0027] 3) Evaporating a layer of metal film with a thickness of 10nm on the organic semiconductor polymer film in step 2);

[0028] 4) The two-dimensional laser interference light field (laser wavelength is 458nm) interacts with the continuous organic semiconductor polymer film to cause a cross-linking reaction of the polymer material and pattern the metal film attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com