Synthetic method for high purity triisopropyl silane

A technology of triisopropylsilane and a synthesis method, applied in the direction of silicon organic compounds and the like, can solve the problems of high price, low reactivity, difficult to remove by-product methoxymagnesium chloride, etc., to reduce impurities that are difficult to separate, prevent secondary effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

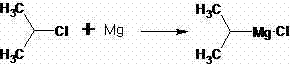

[0018] Step 1: Preparation of Isopropylmagnesium Chloride

[0019] In a 500ml four-necked flask equipped with a stirrer, a thermometer and a condenser tube, add 24g (1mol) of metal magnesium, 240g of a solvent (tetrahydrofuran, methyl tetrahydrofuran, ether, propyl ether, n-butyl ether, dioxane , Ethylene glycol dimethyl ether), heat up to reflux, add 78.5g (1mol) of 2-chloropropane dropwise under reflux, keep reflux for 1h, until the metal magnesium is completely dissolved, and the reaction ends.

[0020] Its reaction formula is as follows:

[0021]

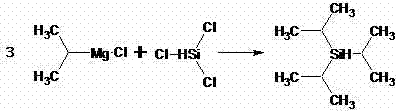

[0022] Step 2: Preparation of Triisopropylsilane

[0023] Cool the four-necked flask in step 1 to below 10°C, add 50g of weak polar solvent (xylene, mesitylene, tetrahydronaphthalene, decahydronaphthalene, n-heptane, cyclohexane, methylcyclohexane among them One), under the protection of nitrogen, add 44.72g (0.33 mol) of trichlorosilane dropwise, after the low-temperature dropwise addition, heat up to about 75°C, reflux fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com