Rheologically modified cleanser for kitchen heavy oily dirt, and preparation method thereof

A rheology modifier and cleaning agent technology, applied in the field of cleaning agents, can solve problems such as rheology and easy loss, and achieve the effect of simple process, fresh smell and good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

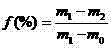

Method used

Image

Examples

Embodiment 1

[0087] Step 1: each component is prepared according to the following mass percentages:

[0088] Rheology modifier 0.2%;

[0089] Tetrasodium glutamate diacetate 0.2%;

[0090] Fatty alcohol polyoxyethylene ether 0.5%;

[0092] Sodium fatty alcohol polyoxyethylene ether sulfate 0.1%;

[0093] Solvent 1%;

[0094] Alkali 0.5%;

[0095] water balance;

[0096] Step 2: Add water to the configuration tank and heat it, control the temperature to 50°C, then add the rheology modifier and tetrasodium glutamic acid diacetate, and stir evenly;

[0097] Step 3: Add fatty alcohol polyoxyethylene ether and sodium fatty alcohol polyoxyethylene ether sulfate under stirring, and stir until completely dissolved;

[0098] Step 4: Add the alkyl glucoside and stir until completely dissolved;

[0099] Step 5: Cool down to 38°C while stirring, add alkali, and stir for 510 minutes;

[0100] Step 6: Add the solvent under stirring, and stir for 20 minutes;

[0101...

Embodiment 2

[0111] The preparation method of a rheology-improved kitchen heavy oil stain cleaner involved in the present invention is realized by the following steps:

[0112] Step 1: each component is prepared according to the following mass percentages:

[0113] Rheology modifier 1%;

[0114] Tetrasodium glutamate diacetate 0.4%;

[0115] Fatty alcohol polyoxyethylene ether 2%;

[0117] Sodium fatty alcohol polyoxyethylene ether sulfate 2%;

[0118] Solvent 2%;

[0119] Alkali 1%;

[0120] Fragrance 0.1%;

[0121] water balance;

[0122] Step 2: Add water to the configuration tank and heat it, control the temperature to 50°C, then add the rheology modifier and tetrasodium glutamic acid diacetate, and stir evenly;

[0123] Step 3: Add fatty alcohol polyoxyethylene ether and sodium fatty alcohol polyoxyethylene ether sulfate under stirring, and stir until completely dissolved;

[0124] Step 4: Add the alkyl glucoside and stir until completely dissolve...

Embodiment 3

[0137] The preparation method of a rheology-improved kitchen heavy oil stain cleaner involved in the present invention is realized by the following steps:

[0138] Step 1: each component is prepared according to the following mass percentages:

[0139] Rheology modifier 1.5%;

[0140] Tetrasodium glutamate diacetate 0.6%;

[0141] Fatty alcohol polyoxyethylene ether 4%;

[0142] Alkyl glucoside 4%;

[0143] Sodium fatty alcohol polyoxyethylene ether sulfate 3%;

[0144] Solvent 4%;

[0145] Alkali 2%;

[0146] Fragrance 0.2%;

[0147] water balance;

[0148] Step 2: Add water to the configuration tank and heat it, control the temperature to 55°C, then add the rheology modifier and tetrasodium glutamic acid diacetate, and stir evenly;

[0149] Step 3: Add fatty alcohol polyoxyethylene ether and sodium fatty alcohol polyoxyethylene ether sulfate under stirring, and stir until completely dissolved;

[0150] Step 4: Add the alkyl glucoside and stir until completely dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com