Novel application of malt oligosaccharide based mycose synthetase and malt oligosaccharide based mycose hydrolase in mycose production

A technology of trehalose synthase and trehalose hydrolase, which is applied in the fields of genetic engineering and enzyme engineering, can solve the problems of susceptible bacteria and low double enzyme activity, and achieves improved stability, improved efficiency, high optimum reaction temperature and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Embodiment 1 bacterial cell culture

[0100] After extensive screening, Arthrobacter oxidans with good activity of MTSase and MTHase ( Arthrobacter oxydans ) TL-3, the strain is deposited in the American Type Culture Collection (ATCC), deposit number: 14358. The medium composition of the strain is: peptone 10 g / L, yeast extract 30 g / L, glucose 10 g / L, MgSO 4 0.06 g / L, KH 2 PO 4 2.13 g / L, K 2 HPO 4 ·3H 2 O 16.43 g / L, pH 7.0. Heat sterilization at 121°C for 15 min.

[0101] The process of cell culture is as follows: After the culture medium is cooled, two rings are taken from the slant bacteria. A . oxydans TL-3 cells were inoculated into a 1000 mL Erlenmeyer flask filled with 200 mL of the above-mentioned medium, and cultured with shaking at 220 rpm and 38°C for 24 h.

Embodiment 2

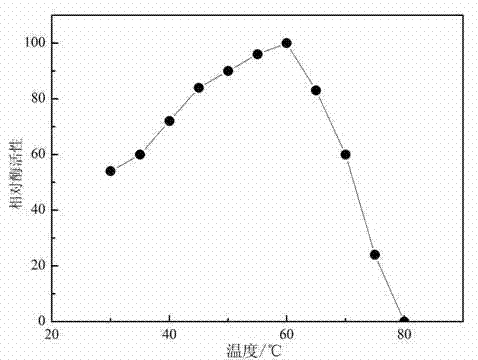

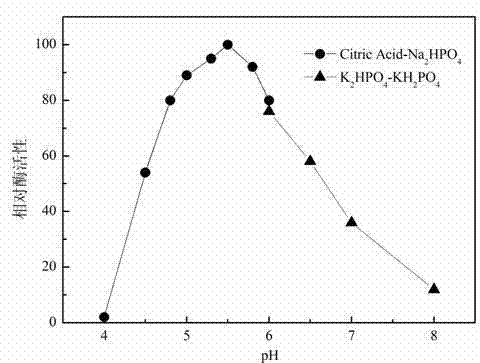

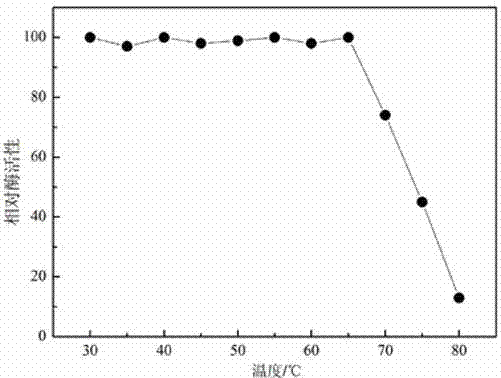

[0102] Example 2 MTSase separation and purification and enzymatic characteristics research

Embodiment 2-1

[0103] Embodiment 2-1 MTSase separation and purification

[0104] (1) Bacterial fragmentation

[0105] Carry out bacterial cell culture according to the method in Example 1, obtain 10 liters of culture, centrifuge at 8000 rpm for 20 min, harvest 150 g of wet bacterial cells, resuspend in buffer, and sonicate the bacterial cells in an ice bath. The buffer composition is 0.2 Mol / L citrate buffer, pH5.5. Centrifuge (10000 r / min, 20 min) after sonication, and take the supernatant to obtain the crude enzyme solution.

[0106] (2) Ammonium sulfate precipitation

[0107] Both ammonium sulfate precipitation and dialysis were carried out in an ice bath. Ammonium sulfate was slowly added to the crude enzyme solution to make the saturation reach 40%, and left overnight at 4°C, then centrifuged at 12000 r / min for 20 min, and sulfuric acid was slowly added to the supernatant Ammonium was used to make the saturation to 60%, centrifuged again, the precipitate was collected and dissolved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com