High-resistance starch barley grass powder rice noodles and making method thereof

A technology of highly resistant starch and barley seedling powder, applied in the field of food processing, can solve the problems of poor taste of barley seedling powder with special health care function, low content of functional components of resistant starch, poor taste of barley seedling powder, etc., and achieves improvement of cerebral thrombosis. The effect of sequelae, maintaining the quality of rice noodle, and increasing the content of functional ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-resistant starch rice Gongmi No. 3 and barley grass powder described in this example are commercially available, and the barley grass powder is barley grass at the jointing stage (very low in resistant starch content), washed and sun-dried. After drying, it is pulverized through a superfine powder machine to obtain barley grass powder. It can be purchased at Kunming Tiankang Technology Co., Ltd. (Address: No. 9 Xueyun Road, Kunming City, Yunnan Province, Zip Code: 650223 or Longtou Street / Yunnan Academy of Agricultural Sciences, Kunming City, Yunnan Province, Zip Code: 650205).

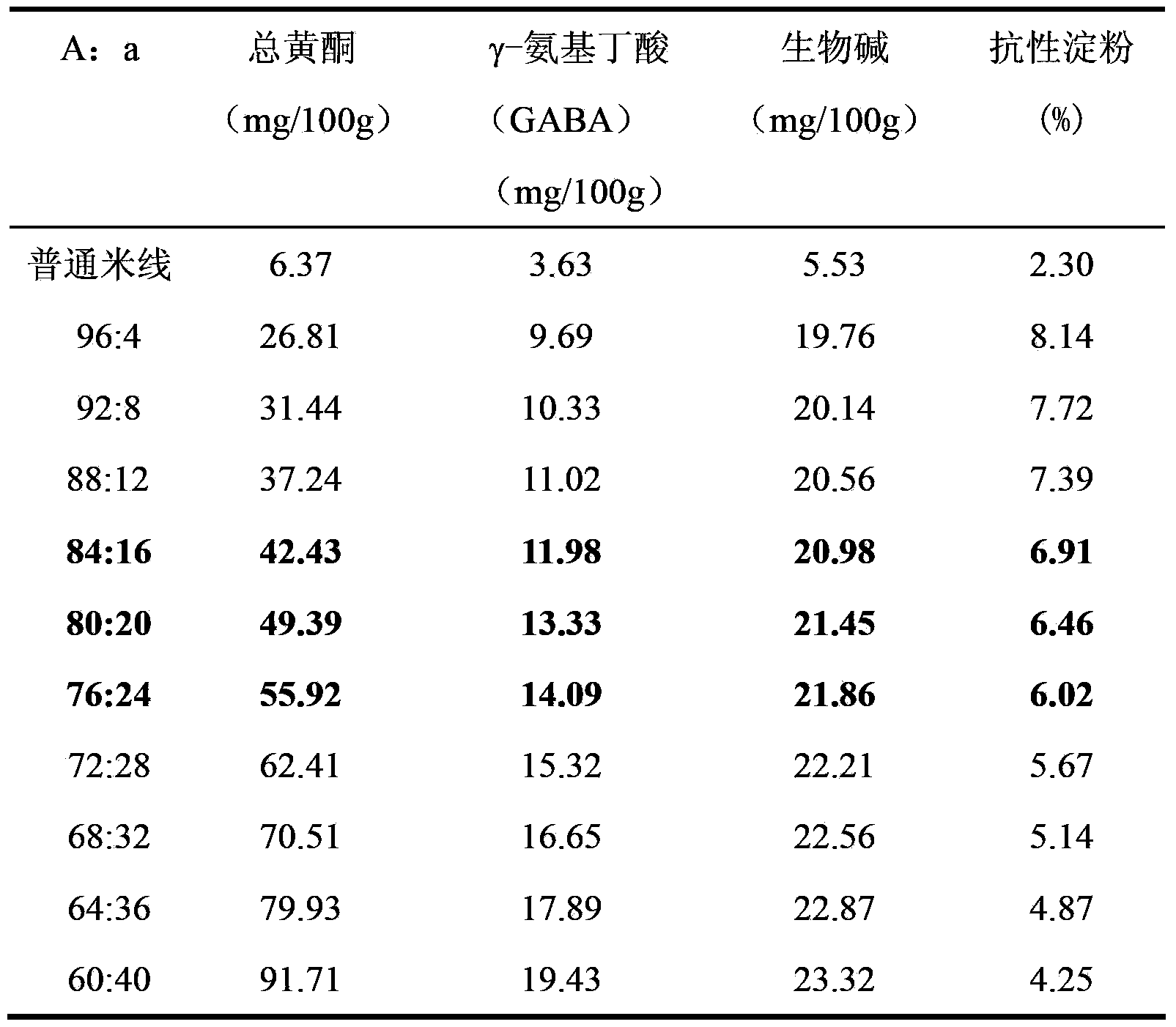

[0034] Considering that adding too much barley grass powder will have a great impact on the taste of the rice noodles made, the addition ratio of barley grass powder was increased by 4% as a unit, and the maximum addition of 40% was tested. Described 10 processings are processing 1~processing 10, and its formula is as follows:

[0035] The raw material formula of treatment 1: by mass ...

Embodiment 2

[0046] Embodiment 2 The preparation method of high resistant starch barley grass powder rice noodle

[0047] (1) Raw material preparation: Wash the high-resistant starch rice, dry it until the moisture content is 11-12%, and then grind it through 80 meshes to obtain rice flour. Rice with starch ≥ 8% processed polished rice or rice with resistant starch ≥ 10% in cooked rice; barley seedlings at the jointing stage are cut, washed and sun-dried until the water content is 11-12%, then pulverized, and passed through a superfine powder machine Obtain barley grass powder; said percentage is mass fraction.

[0048] (2) Add the rice flour to 40% of the mass of the rice flour and stir evenly, put it in a steamer and steam for 1 hour;

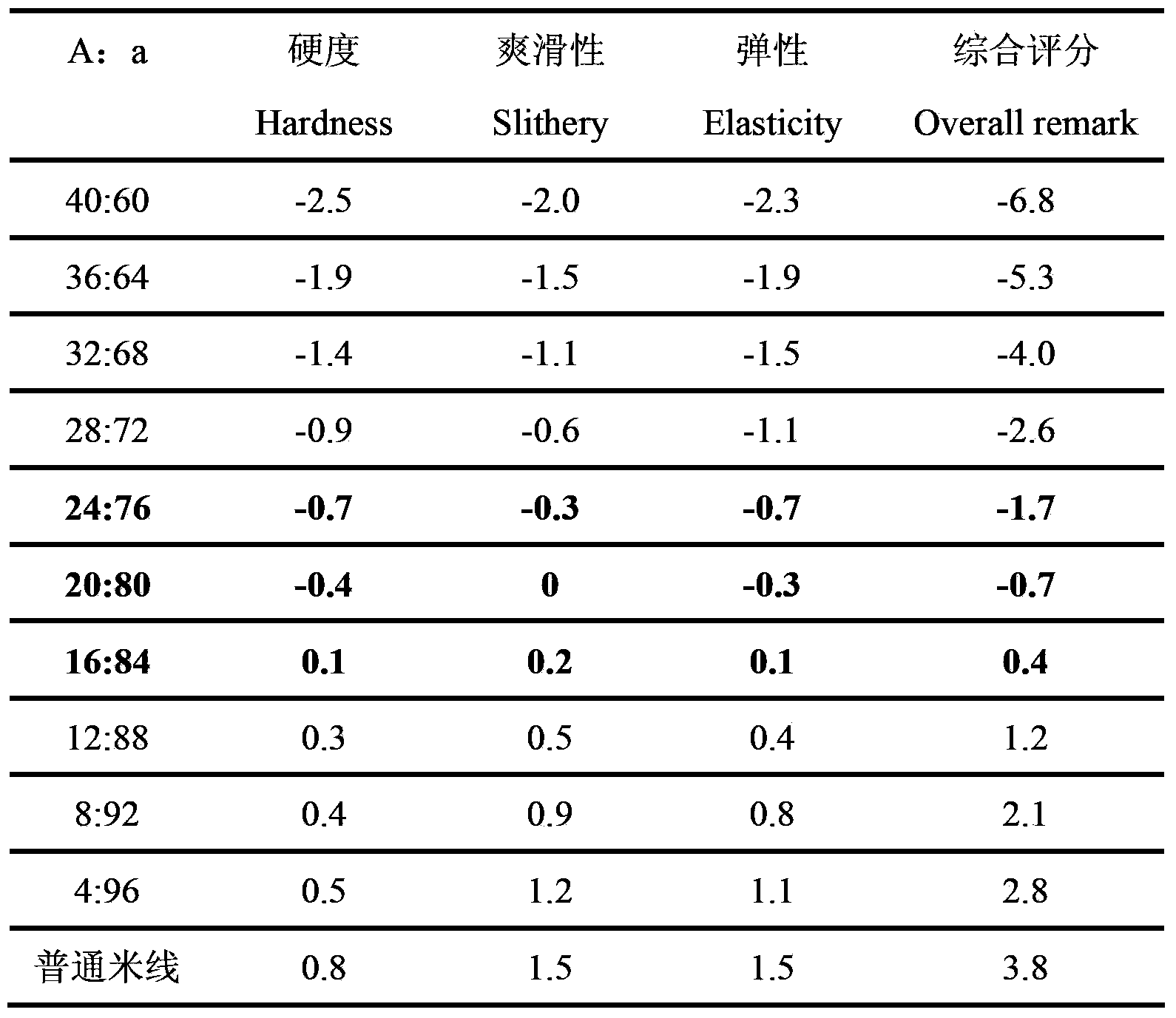

[0049] (3) In terms of mass fraction, the amount of barley grass powder is 16% to 24% of that of high-resistant starch rice. Mix barley grass powder and steamed rice flour evenly and put them into a rice noodle machine to make high-resistant starch rice....

Embodiment 3

[0051] Example 3 Analysis of the functional component content of the high resistant starch barley grass powder rice noodle of the present invention and the functional component content of the control and sensory evaluation of the rice noodle

[0052] The sample to be tested was prepared according to the mass ratio of steamed rice flour and barley grass powder shown in Example 1, and the high-resistant starch barley grass powder rice noodle was prepared according to the production method described in Example 2.

[0053] Contrast promptly with the commonly used rice (i.e. common rice, hereinafter referred to as common rice) of existing processed rice noodle as the rice noodle processed by prior art (the rice noodle made claims conventional rice noodle) as raw material.

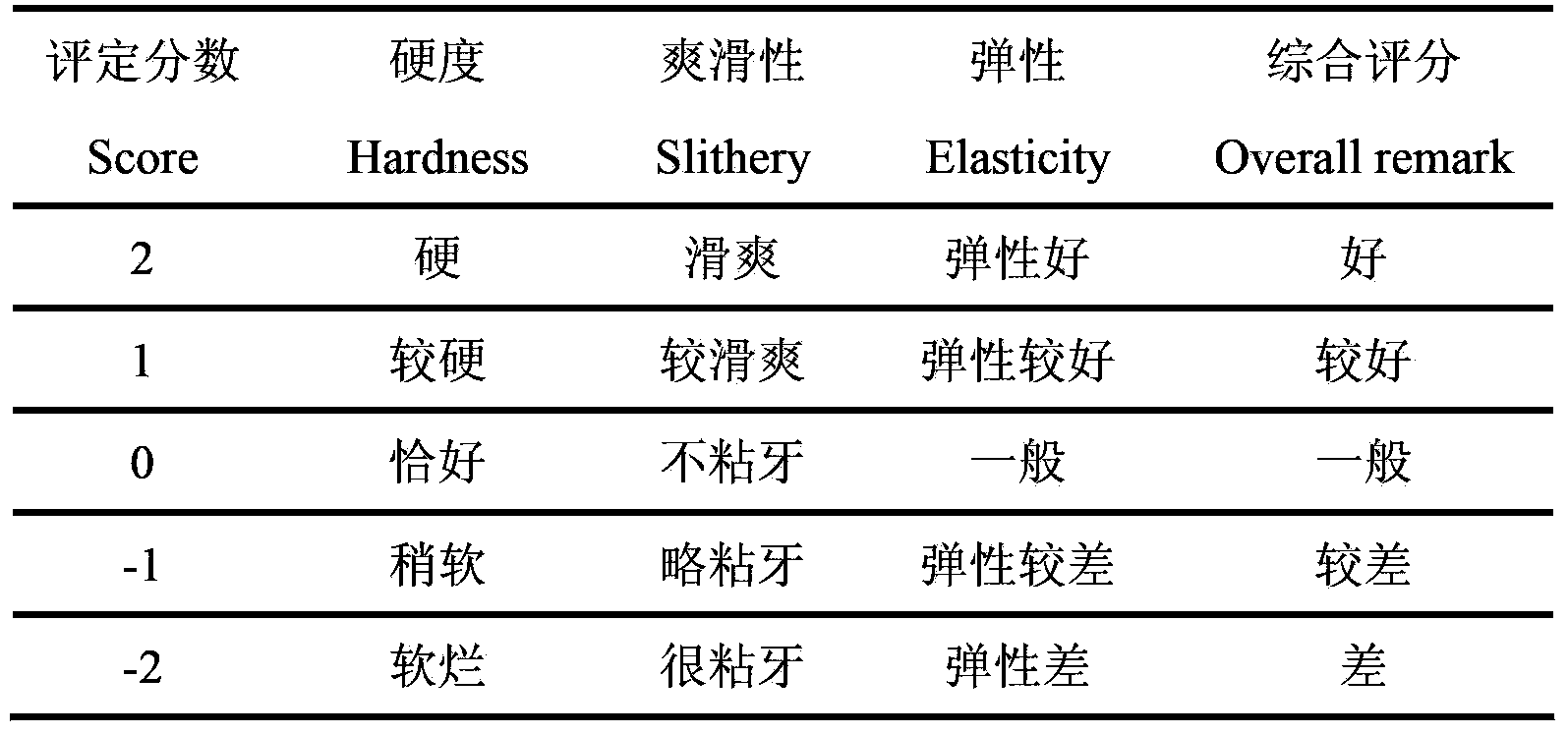

[0054] The samples to be tested and the control were tested for the content of total flavonoids, γ-aminobutyric acid (GABA), alkaloids, and resistant starch according to the following conventional methods, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com