Cerium oxide/titanium dioxide nano belt surface heterostructure photocatalyst with capture-catalysis performance and preparation method thereof

A technology of titanium dioxide and catalytic performance, applied in the field of photocatalytic materials and their surface modification, to achieve significant photocatalytic enhancement effect, large specific surface area, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

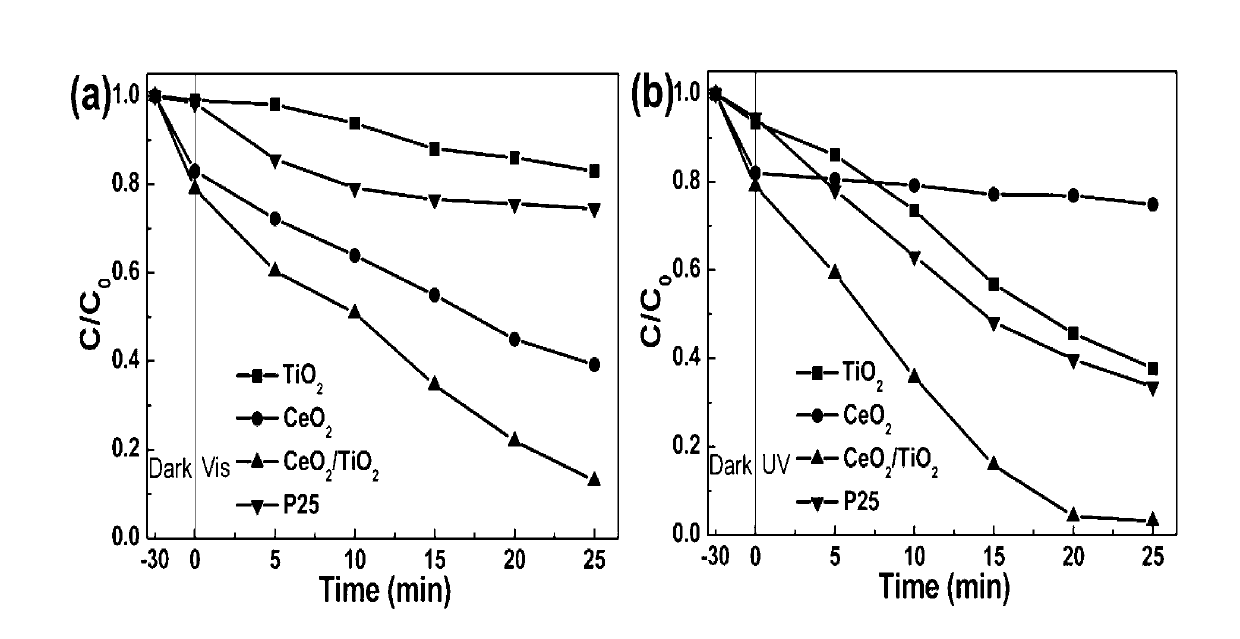

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix cerium nitrate and titanium dioxide nanobelts with a molar ratio of 1:10, fully dissolve in deionized water to form a transparent solution, add ammonia water dropwise to the transparent solution, adjust the pH value of the solution to 10, and magnetically stir for 1 hour, and then The stirred solution was placed in a hydrothermal reaction kettle and reacted for 48 hours at 100° C., filtered the reacted solution, washed the generated precipitate with deionized water, and then separated the separated precipitate at 80° C. for 12 hours. The precipitate after the heat preservation treatment was annealed at 550°C for 2 hours to obtain a cerium oxide / titania nanobelt surface heterogeneous structure photocatalyst with capture-catalysis properties, wherein the width of the titanium dioxide nanobelt was 50-200nm, The thickness is 20-40nm, and the diameter of the cerium oxide nanoparticles grown in liquid phase on the titania nanobelt is 6±2nm.

Embodiment 2

[0020] Mix cerium nitrate and titanium dioxide nanobelts with a molar ratio of 2:10, fully dissolve in deionized water to form a transparent solution, add ammonia water dropwise to the transparent solution, adjust the pH value of the solution to 10, and magnetically stir for 1 hour, and then The stirred solution was placed in a hydrothermal reaction kettle and reacted for 48 hours at 100° C., filtered the reacted solution, washed the generated precipitate with deionized water, and then separated the separated precipitate at 80° C. for 12 hours. The precipitate after the heat preservation treatment was annealed at 550°C for 2 hours to obtain a cerium oxide / titania nanobelt surface heterogeneous structure photocatalyst with capture-catalysis properties, wherein the width of the titanium dioxide nanobelt was 50-200nm, The thickness is 20-40nm, and the diameter of the cerium oxide nanoparticles grown in liquid phase on the titania nanobelt is 6±2nm.

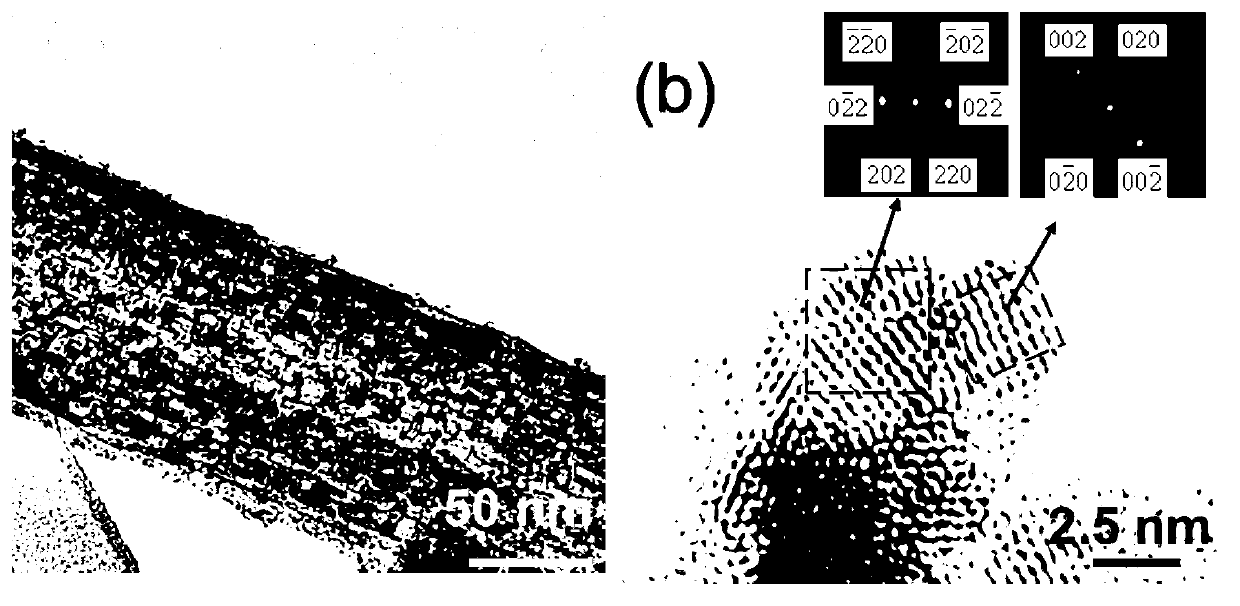

[0021] The TEM, HRTEM, and se...

Embodiment 3

[0023] Mix cerium nitrate and titanium dioxide nanobelts with a molar ratio of 1:1, fully dissolve them in deionized water to form a transparent solution, add ammonia water dropwise to the transparent solution, adjust the pH value of the solution to 10, and magnetically stir for 1 hour, then place The stirred solution was placed in a hydrothermal reaction kettle and reacted for 48 hours at 100° C., filtered the reacted solution, washed the generated precipitate with deionized water, and then separated the separated precipitate at 80° C. for 12 hours. The precipitate after the heat preservation treatment was annealed at 550°C for 2 hours to obtain a cerium oxide / titania nanobelt surface heterogeneous structure photocatalyst with capture-catalysis properties, wherein the width of the titanium dioxide nanobelt was 50-200nm, The thickness is 20-40nm, and the diameter of the cerium oxide nanoparticles grown in liquid phase on the titania nanobelt is 6±2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com