Insulator vacuum pugging method and insulator vacuum pugging device

A technology of vacuum refining mud and porcelain sleeves, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve problems affecting normal production and economic benefits of enterprises, and achieve the effects of not being easy to bend, saving labor and labor, and having a dense molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Describe the specific embodiment of the present invention in detail below in conjunction with accompanying drawing

[0013] Concrete practice mud step of the present invention is as follows:

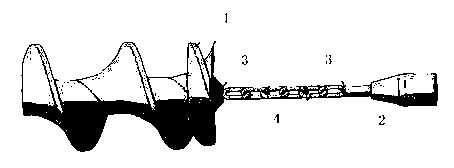

[0014] 1. Install 1-2 disc plane bearings 3 in the center hole of the spiral blade 1 at the end of the three-blade mud training machine and the tapered end of the tapered mud training bowl 2, and the specification model is 51304 or 51306.

[0015] 2. Change the connection between the conical mud training machine bowl 2 and the screw blade 1 at the end of the three-blade mud training machine from a solid iron connecting rod to a high-strength drag chain 4, and its specification is an 80-grade lifting chain 6x8 or 7x21.

[0016] 3. Adjust the length of the flat extension part of the conical clay training bowl 2 to 300-400mm.

[0017] 4. Weld one end of the high-strength drag chain 4 to a Ф25-30mm, 50-80mm long circular member with screws to connect with the spiral leaf 1 at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com