Oil-refining wastewater treatment method and device

A technology for oil refining wastewater and treatment method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and impact resistance, the effect of reducing the inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

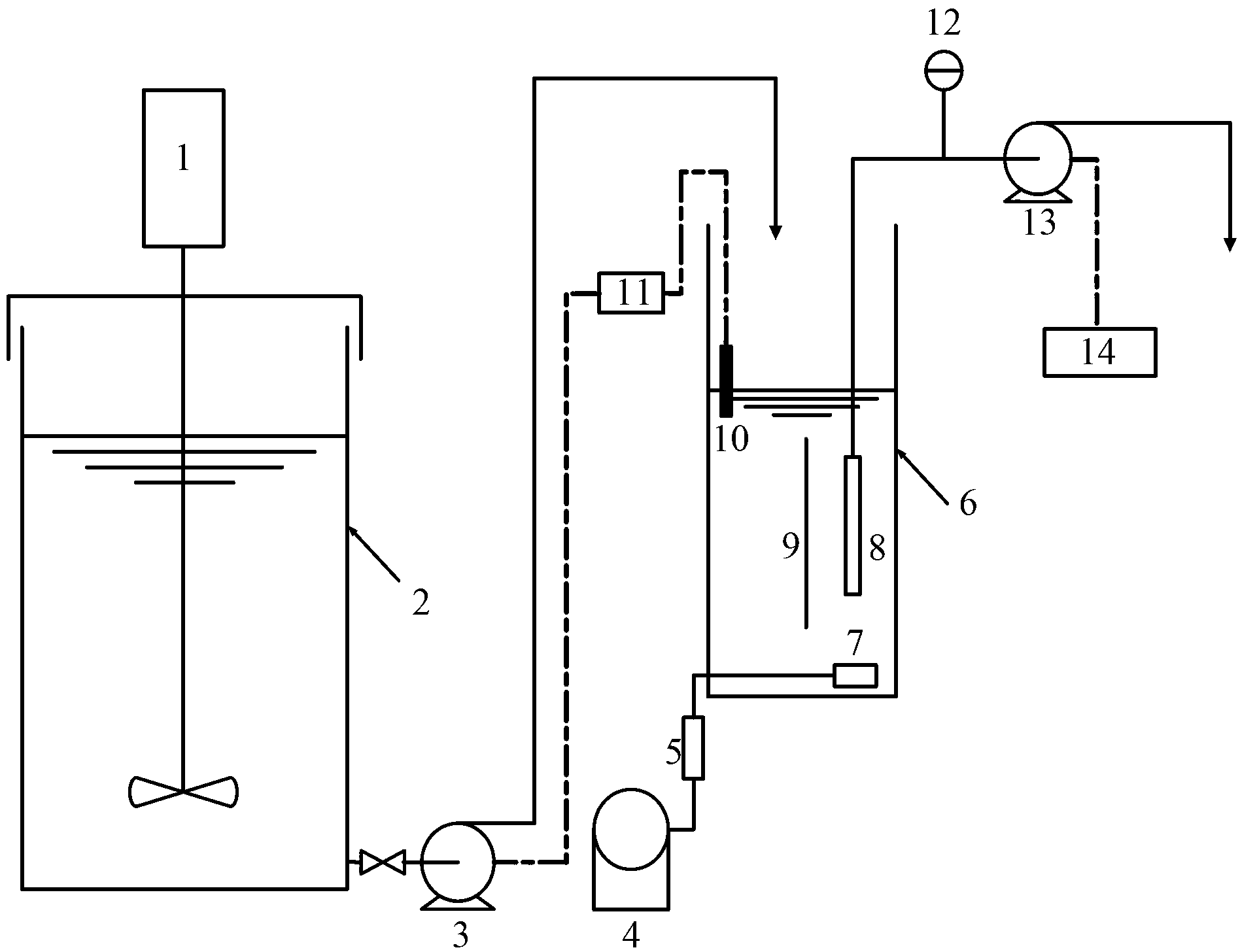

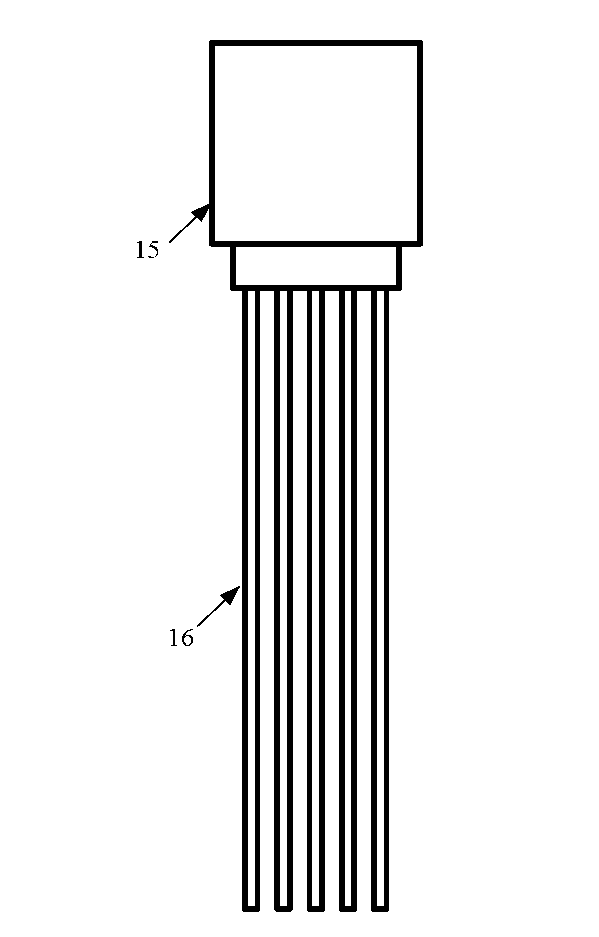

Method used

Image

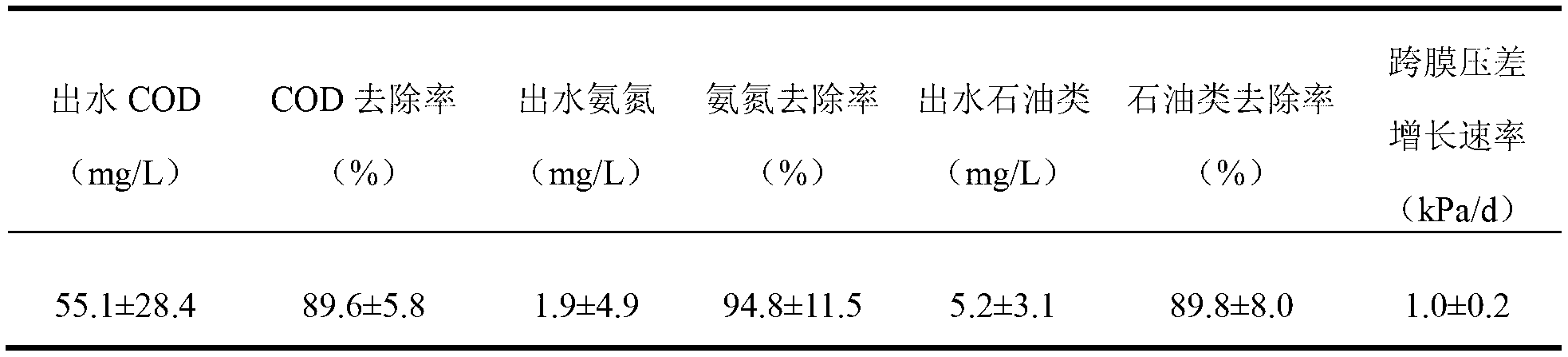

Examples

Embodiment

[0032] The inoculated activated sludge is the return sludge from the secondary settling tank of the activated sludge process of an oil refinery, and the domestication culture water and the inflow water of the air-lift internal circulation membrane bioreactor 6 during official operation are the effluent of the air flotation unit of an oil refinery. The activated sludge is inoculated into the air-lift internal circulation membrane bioreactor 6, and the initial MLSS is 5g / L, and the domestication culture is carried out according to the SBR method. When the COD removal rate is stable above 80% and the microbial microscopic examination is in good condition, install the membrane module 8 and add powdered activated carbon (particle size 100-120 mesh), the dosage of powdered activated carbon is 1g of powder per 1L of mixed solution Activated carbon, continue to be domesticated and cultivated according to the SBR method for 4 days, after 4 days, it will start to enter water continuously...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com