Method for producing color facing mortar

A technology of colored facing mortar and facing mortar, applied in the field of colored facing mortar, can solve the problems of mortar surplus, product backlog, waste, etc., and achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The basic components of white mortar include cement, redispersible latex powder, powdered calcium carbonate (with a particle size of 50 μm), water reducer, and the aggregate is quartz sand (with a particle size of 2-4 mm), according to the weight ratio in Table 1 The materials were weighed, mixed evenly, and the whiteness of the basic components of the mortar was measured to be 65.66.

[0055] Table 1, the weight ratio of mortar base components and aggregate materials in Example 1 (unit: kg)

[0056] material

Redispersible latex powder

Polycarboxylate superplasticizer

Quartz sand

weight

20

6

66.5

0.5

7

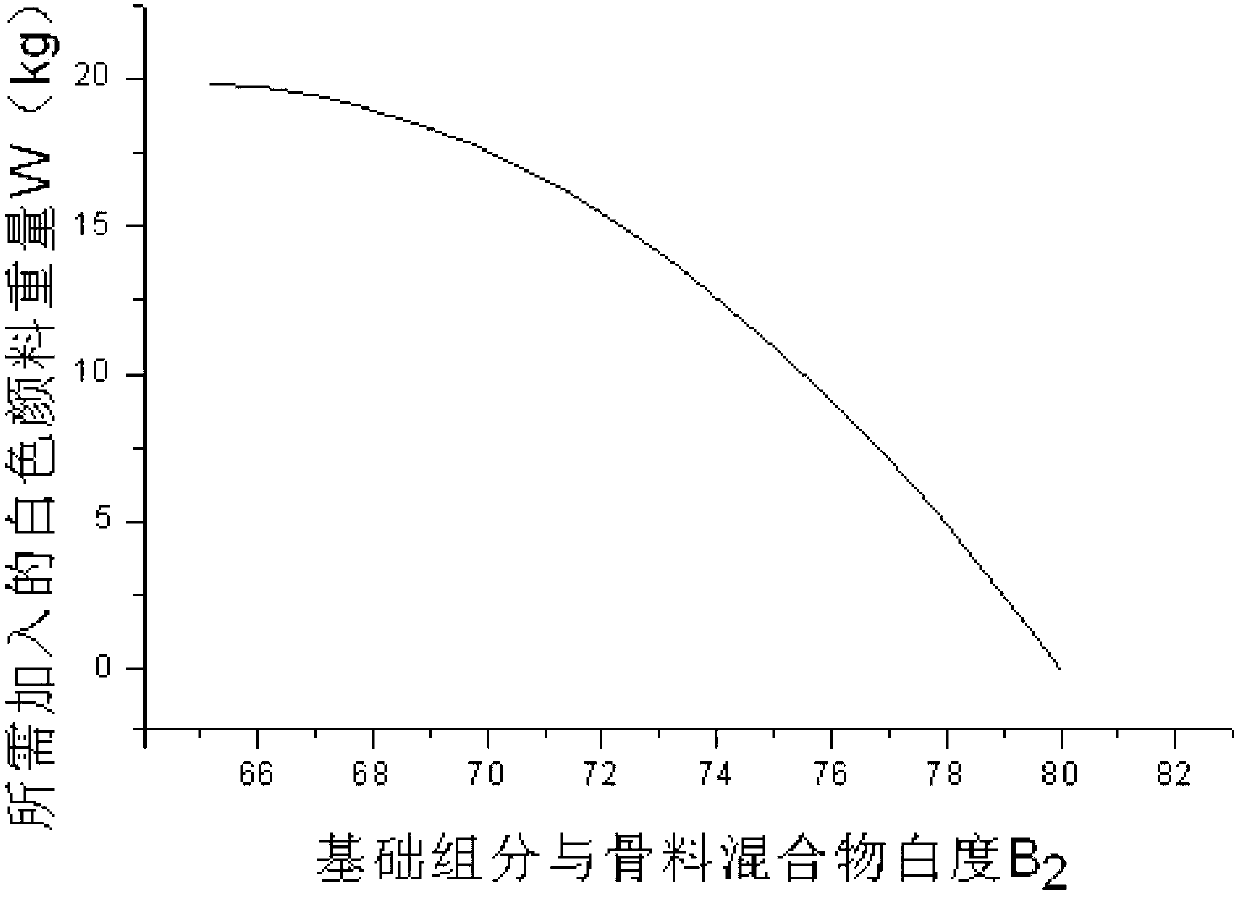

[0057] According to the B drawn in the above 2 From the relationship curve between W and W, find the ordinate value 19.80 of the point on the curve corresponding to the abscissa value of 65.66, which is the weight of the white pigment that needs to be added.

[0058] Weig...

Embodiment 2

[0062] The basic components of mortar include cement, redispersible latex powder, powdered calcium carbonate (300 mesh in particle size), water reducing agent, and quartz sand (3mm in particle size) as the aggregate, weighed according to the weight ratio in Table 2 The materials were mixed evenly, and the whiteness of the basic components of the mortar was detected to be 69.03.

[0063] Table 2, the weight ratio of mortar base components and aggregate materials in Example 2 (unit: kg)

[0064] material

Redispersible latex powder

Polycarboxylate superplasticizer

Quartz sand

weight

20

6

66.5

0.5

7

[0065] According to the relationship curve between B1 and W drawn in the above content, find the ordinate value 18.20 of the point on the curve corresponding to the abscissa value of 69.03, which is the weight of the white pigment to be added.

[0066] Weigh 18.20kg of white pigment, ad...

Embodiment 3

[0069] The basic components of mortar include cement, redispersible latex powder, powdered calcium carbonate (particle size: 300 mesh), water reducer, aggregate is quartz sand (particle size: 3mm), weighed according to the weight ratio in Table 3 The materials were mixed evenly, and the whiteness of the mortar base component and aggregate mixture was measured to be 72.32.

[0070] Table 3, the weight ratio of mortar base components and aggregate materials in Example 3 (unit: kg)

[0071] material

Redispersible latex powder

Polycarboxylate superplasticizer

Quartz sand

weight

20

6

66.5

0.5

7

[0072] According to the relationship curve between B1 and W drawn in the above content, find the ordinate value 15.10 of the point on the curve corresponding to the abscissa value of 72.32, which is the weight of the white pigment to be added.

[0073] Weigh 15.10kg of white pigment, add it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com