Method for preparing 10-(2,5-hydroxyphenyl)-10-H-9-oxa-10-phosphaphenanthrene-10-oxide

A technology of dihydroxyphenyl and phosphaphenanthrene is applied in the field of preparation of phosphorus-containing reactive flame retardant intermediates, which can solve the problems of easy decomposition and poor stability in the application process, and achieve simple and easy-to-control operation, low equipment investment, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

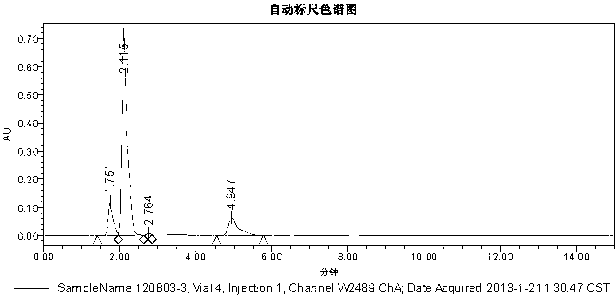

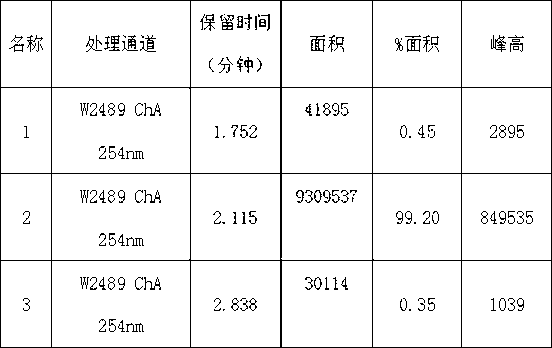

[0030]Add 31.4g of BQ and 0.78g of activated carbon into 55.9g of tetrahydrofuran, raise the temperature to 50°C, dissolve BQ in the solvent tetrahydrofuran under stirring, and filter while it is hot to obtain feed liquid A; (2) While preparing feed liquid A, Add 59.4g DOPO into 54.1g tetrahydrofuran, raise the temperature to 50°C, and dissolve DOPO into tetrahydrofuran under stirring to obtain feed liquid B; add feed liquid A dropwise to feed liquid B while it is hot, and add dropwise for 30 minutes while stirring After the dropwise addition is completed, the reaction system formed by the feed liquid A and the feed liquid B is first carried out a 30-minute preliminary reaction at a temperature of 60° C. and under agitation, and then 0.59 g of zinc stearate is added to the reaction system. The reaction system continued to carry out the post-reaction for 3 hours at 65°C under stirring conditions. After the reaction was completed, the reaction system was cooled until the solid pr...

Embodiment 2

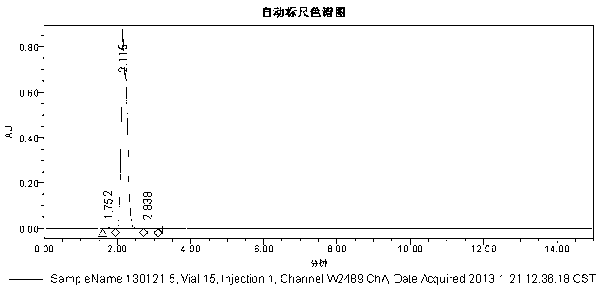

[0032] Add 29.7g of BQ and 1.19g of diatomaceous earth into 56.4g of toluene, raise the temperature to 70°C, dissolve BQ in the solvent toluene under stirring, and filter while it is hot to obtain feed liquid A; (2) Preparation of feed liquid A At the same time, add 59.4g DOPO into 59.4g toluene, raise the temperature to 70°C, dissolve DOPO into toluene under stirring, and obtain material liquid B; After 40 minutes, after the dropwise addition is completed, the reaction system formed by the feed liquid A and the feed liquid B is firstly reacted for 40 minutes at a temperature of 90° C. and stirred, and then 0.89 g of magnesium stearate is added to the reaction system. Under the condition of stirring at a temperature of 105°C, the reaction system continued to carry out the post-reaction for 4 hours. After the reaction was completed, the reaction system was cooled until the solid product was fully separated, and 92.56 g of the solid product obtained by filtering the reaction syst...

Embodiment 3

[0034] Add 32.67g of BQ and 1.96g of activated carbon into 71.9g of chlorobenzene, raise the temperature to 90°C, dissolve BQ in the solvent chlorobenzene under stirring, and filter while it is hot to obtain feed liquid A; (2) Prepare feed liquid A At the same time, add 59.4g DOPO into 83.2g chlorobenzene, raise the temperature to 90°C, and dissolve DOPO into chlorobenzene under stirring to obtain feed liquid B; while hot, add feed liquid A dropwise into feed liquid B, and stir under Add dropwise for 50 minutes. After the dropwise addition is completed, make the reaction system formed by feed liquid A and feed liquid B under stirring conditions at a temperature of 110°C for 50 minutes of preliminary reaction, and then add 1.19 g of stearic acid into the reaction system Lead, under the temperature of 125 ℃ and stirring conditions, make the reaction system continue to carry out the post-reaction for 5 hours. After the reaction is completed, cool the reaction system until the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com