Carbon fiber/epoxy resin composite material and preparation method thereof

A composite material and epoxy resin technology, applied in the field of composite materials, can solve the problems of secondary environmental hazards, a large amount of corrosive hydrogen halide gas, etc., and achieve the effects of good flame retardant effect, easy mass production, and easy dispersion in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

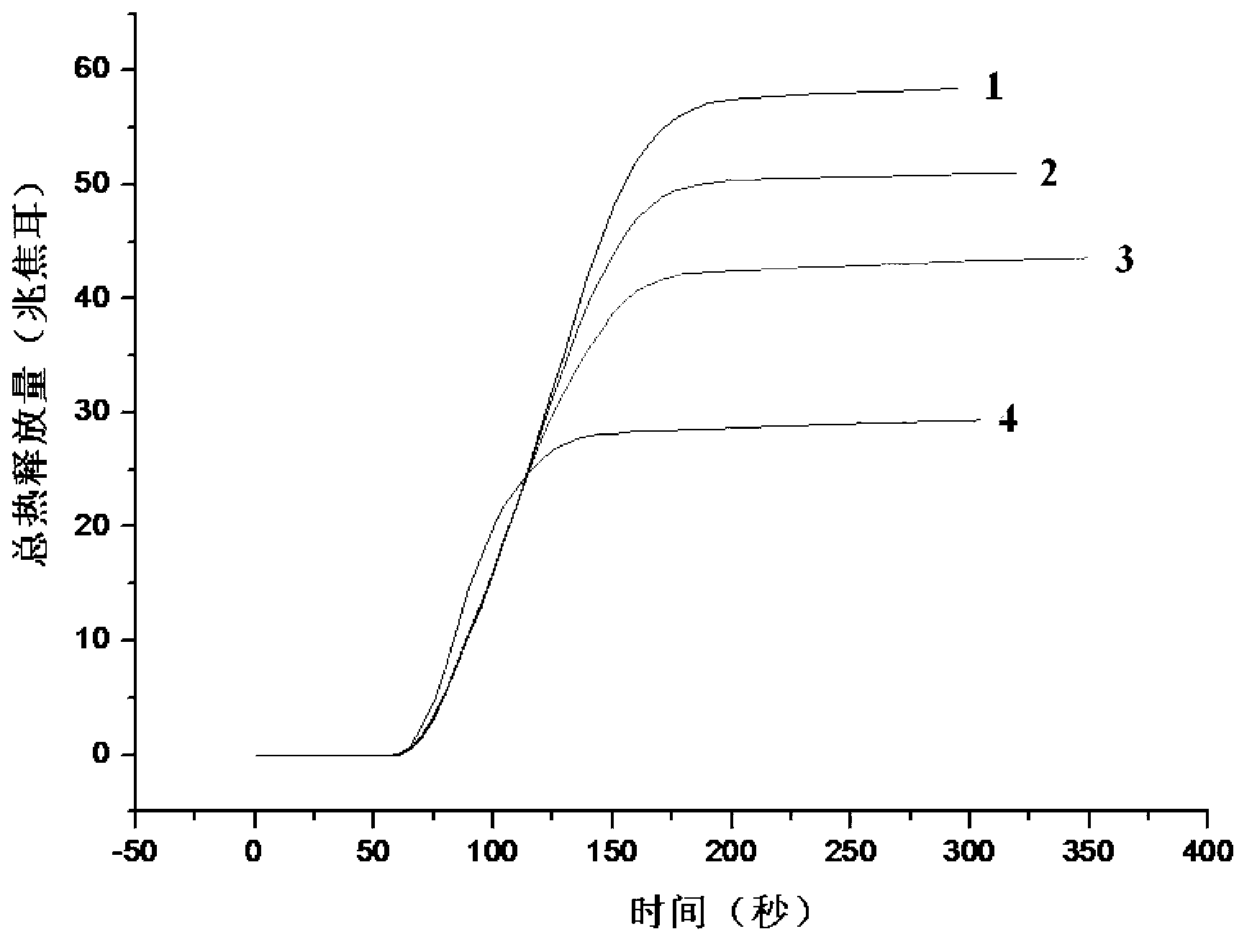

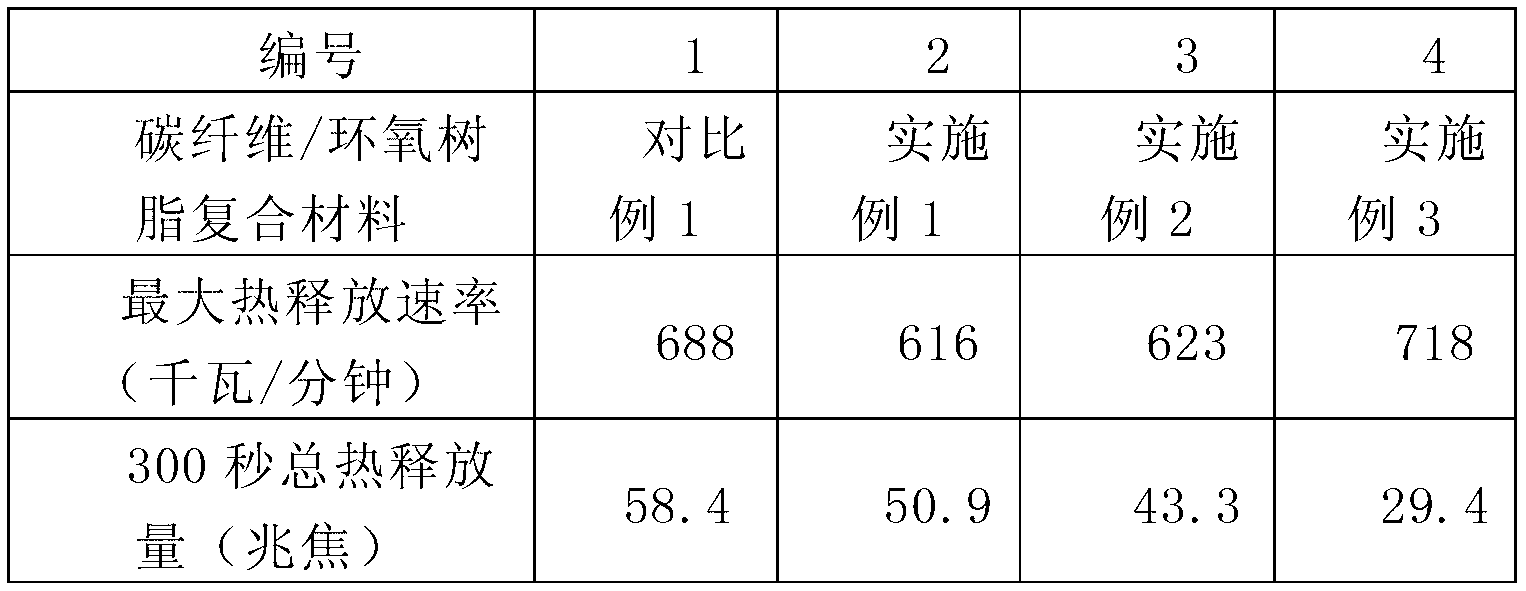

[0025] This embodiment provides a preparation method for preparing carbon fiber / epoxy resin composite material, comprising the following steps:

[0026] (1) Add 6.5 parts by mass of flame retardant resorcinol bis(diphenyl phosphate) (RDP for short) to 100 parts by mass of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin), and then add 12 parts by mass of diluent ethanol, stirred for 1 hour, and placed in a 40°C oven for 1 hour. Among them, the viscosity of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) at 25°C is 1100cps.

[0027] (2) Take out the mixture of flame retardant resorcinol bis(diphenyl phosphate) and liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) from the oven, and then add 30 parts by mass of curing agent (DOW Voraforce TF350Hardener) , and stir for 5 minutes. Wherein, the mass of the flame retardant resorcinol bis(diphenyl phosphate) in step (1) is 5% of the mass sum of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) and curing agent (DOW Vorafo...

Embodiment 2

[0036] This embodiment provides a preparation method for preparing carbon fiber / epoxy resin composite material, comprising the following steps:

[0037] (1) Add 19.5 parts by mass of flame retardant resorcinol bis(diphenyl phosphate) (RDP for short) to 100 parts by mass of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin), and then add 15 parts by mass of Diluent mixed solvent of ethanol and acetone, stirred for 1 hour, and placed in an oven at 40° C. for 1 hour. Among them, the viscosity of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) at 25°C is 1100cps.

[0038](2) Take out the mixture of flame retardant resorcinol bis(diphenyl phosphate) and liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) from the oven, and then add 30 parts by mass of curing agent (DOW Voraforce TF350Hardener) , and stir for 5 minutes. Wherein, the mass of the flame retardant resorcinol bis(diphenyl phosphate) in step (1) is 15% of the mass sum of liquid epoxy resin (DOW Voraforce TF301Epoxy...

Embodiment 3

[0041] This embodiment provides a preparation method for preparing carbon fiber / epoxy resin composite material, comprising the following steps:

[0042] (1) Add 32.5 parts by mass of flame retardant resorcinol bis(diphenyl phosphate) (RDP for short) to 100 parts by mass of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin), and then add 10 parts by mass of Diluent ethyl acetate, stirred for 1 hour, and placed in a 40°C oven for 1 hour. Among them, the viscosity of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) at 25°C is 1100cps.

[0043] (2) Take out the mixture of flame retardant resorcinol bis(diphenyl phosphate) and liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) from the oven, and then add 30 parts by mass of curing agent (DOW Voraforce TF350Hardener) , and stir for 5 minutes. Wherein, the mass of the flame retardant resorcinol bis(diphenyl phosphate) in step (1) is 25% of the mass sum of liquid epoxy resin (DOW Voraforce TF301Epoxy Resin) and curing agent (DO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com