Rhodium reduction activation dissolution method

A technology of activator and rhodium waste, which is applied in the field of precious metal metallurgy, can solve the problems of slow dissolution speed and achieve the effects of low dissolution temperature, short process flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

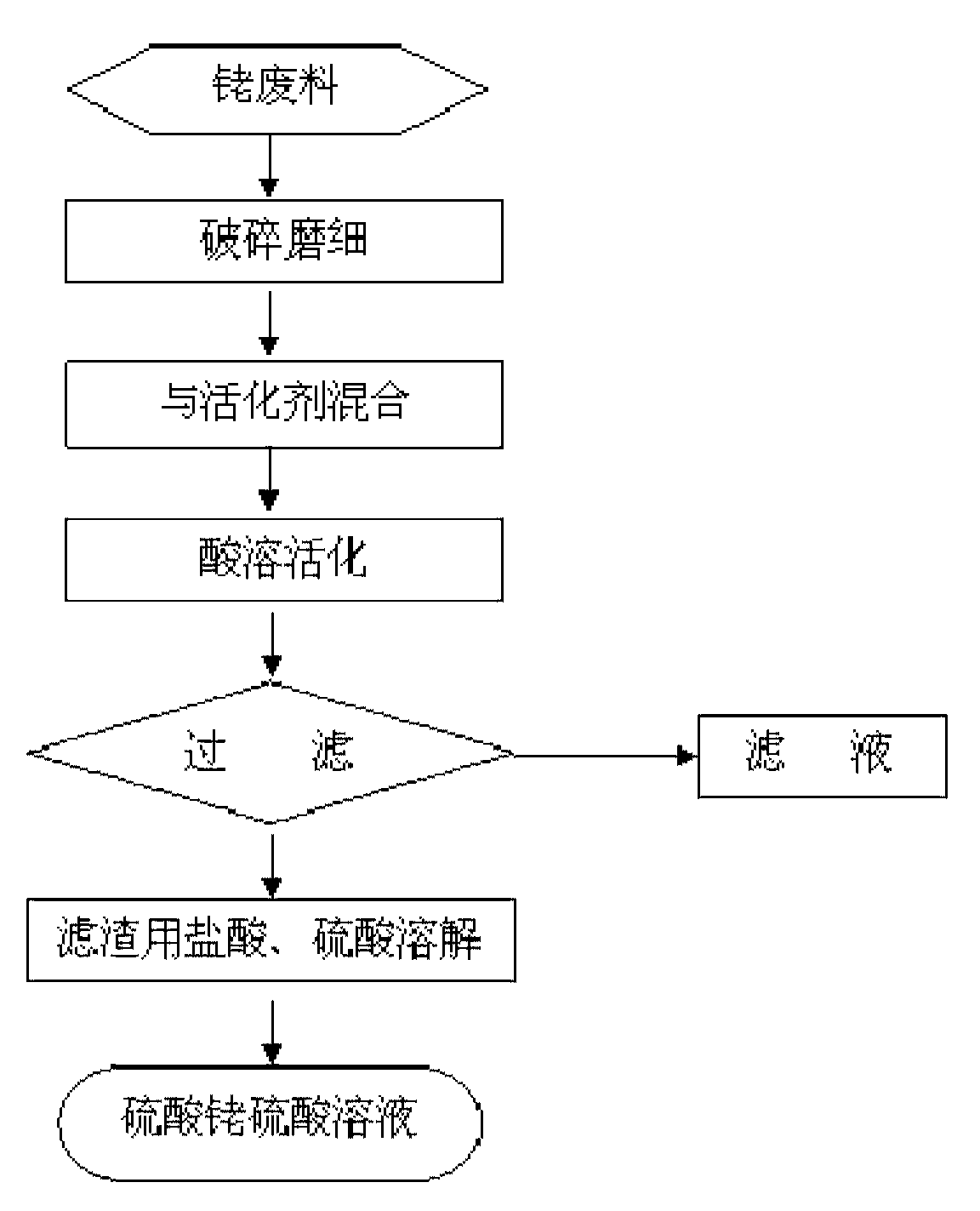

Method used

Image

Examples

Embodiment 1

[0024] A, rhodium waste crushing and grinding: 100 grams of waste platinum catalytic network aqua regia insoluble residue, rhodium content is 82.23%, rhodium 82.23 grams, crushing and grinding with disc crusher, cross 300 mesh sieves.

[0025] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 300 grams of 200 mesh zinc powders.

[0026] C. Acid dissolution activation: In a closed 2L glass reactor, first add 800ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 10mol / L, add the mixture while stirring, the stirring speed is 120 rpm, and the reaction rises to 95°C. Keep warm for 60 minutes.

[0027] D. Filtration: filter the solution after the reaction in step C to obtain a filter residue, wash the filter residue 8 times with hot water at 75° C. for 3 times to obtain a reduced and activated rhodium material.

[0028] E. Dissolution: Put the reduced and activated rhodium material obtained in step ...

Embodiment 2

[0030] A, rhodium waste crushing and grinding: 100 grams of organic rhodium waste slag, rhodium content is 18.67%, containing rhodium 18.67 grams, crushing and grinding with disc crusher, cross 280 mesh sieves.

[0031] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 200 grams of 250 mesh zinc powders.

[0032]C. Acid dissolution activation: In a closed 2L glass reactor, first add 500ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 12mol / L, add the mixture while stirring, the stirring speed is 80 rpm, and the reaction rises to 60°C. Keep warm for 80 minutes.

[0033] D. Filtration: Filter the solution after the step C reaction is completed to obtain a filter residue, which is washed twice with hot water at 85°C 12 times the filter residue to obtain a reduced and activated rhodium material.

[0034] E. Dissolution: Put the reductively activated rhodium material obtained in step D into a gla...

Embodiment 3

[0036] A, rhodium waste crushing and grinding: coarse rhodium powder 100 grams, content 98.10%, containing 98.1 grams of rhodium, crushing and grinding with disc crusher, cross 200 mesh sieves.

[0037] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 500 grams of 300 mesh zinc powders.

[0038] C. Acid dissolution activation: In a closed 3L glass reactor, first add 1000ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 11mol / L, add the mixture while stirring, the stirring speed is 80 rpm, and the reaction rises to 80°C. Keep warm for 40 minutes.

[0039] D. Filtration: filter the solution after the reaction in step C to obtain a filter residue, and wash the filter residue once with hot water at 80°C 10 times of the filter residue to obtain a reduced and activated rhodium material.

[0040] E. Dissolution: Put the reductively activated rhodium material obtained in step D into a glass reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com