Rhodium reduction activation dissolution method

A technology of rhodium waste and technical solutions, which is applied in the field of rhodium dissolution and can solve problems such as slow dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

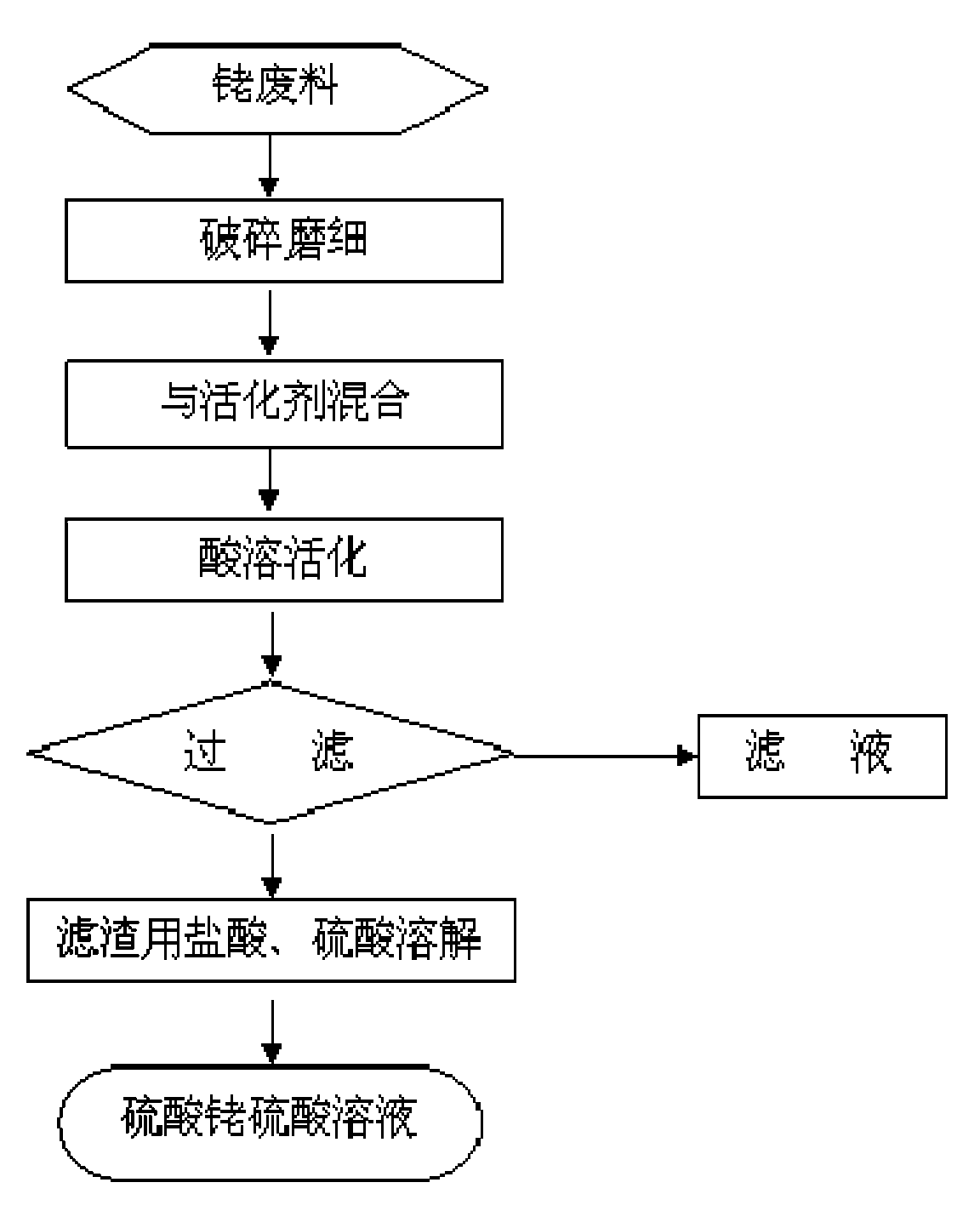

Method used

Image

Examples

Embodiment 1

[0024] A, rhodium waste crushing and grinding: 100 grams of waste platinum catalytic network aqua regia insoluble residue, rhodium content is 82.23%, rhodium 82.23 grams, crushing and grinding with disc crusher, cross 300 mesh sieves.

[0025] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 300 grams of 200 mesh zinc powders.

[0026] C. Acid dissolution activation: In a closed 2L glass reactor, first add 800ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 10mol / L, add the mixture while stirring, the stirring speed is 120 rpm, and the reaction rises to 95°C. Keep warm for 60 minutes.

[0027] D. Filtration: filter the solution after the reaction in step C to obtain a filter residue, wash the filter residue 8 times with hot water at 75° C. for 3 times to obtain a reduced and activated rhodium material.

[0028] E. Dissolution: Put the reduced and activated rhodium material obtained in step ...

Embodiment 2

[0030] A, rhodium waste crushing and grinding: 100 grams of organic rhodium waste slag, rhodium content is 18.67%, containing rhodium 18.67 grams, crushing and grinding with disc crusher, cross 280 mesh sieves.

[0031] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 200 grams of 250 mesh zinc powders.

[0032]C. Acid dissolution activation: In a closed 2L glass reactor, first add 500ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 12mol / L, add the mixture while stirring, the stirring speed is 80 rpm, and the reaction rises to 60°C. Keep warm for 80 minutes.

[0033] D. Filtration: Filter the solution after the step C reaction is completed to obtain a filter residue, which is washed twice with hot water at 85°C 12 times the filter residue to obtain a reduced and activated rhodium material.

[0034] E. Dissolution: Put the reductively activated rhodium material obtained in step D into a gla...

Embodiment 3

[0036] A, rhodium waste crushing and grinding: coarse rhodium powder 100 grams, content 98.10%, containing 98.1 grams of rhodium, crushing and grinding with disc crusher, cross 200 mesh sieves.

[0037] B, mix with activator: the rhodium waste material after the crushing that step A makes is fully mixed with 500 grams of 300 mesh zinc powders.

[0038] C. Acid dissolution activation: In a closed 3L glass reactor, first add 1000ml of industrial hydrochloric acid, the concentration of hydrochloric acid is 11mol / L, add the mixture while stirring, the stirring speed is 80 rpm, and the reaction rises to 80°C. Keep warm for 40 minutes.

[0039] D. Filtration: filter the solution after the reaction in step C to obtain a filter residue, and wash the filter residue once with hot water at 80°C 10 times of the filter residue to obtain a reduced and activated rhodium material.

[0040] E. Dissolution: Put the reductively activated rhodium material obtained in step D into a glass reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com