Preparation method of BiFeO3 sodium-ion battery anode material

A technology for sodium ion battery and anode material, which is applied in the field of preparation of anode material for sodium ion battery, can solve the problems of increasing the proportion of material cost, the safety problem of lithium battery is not fundamentally solved, restricting and the like, and achieves high capacity and improves capacity. , the effect of improving the degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

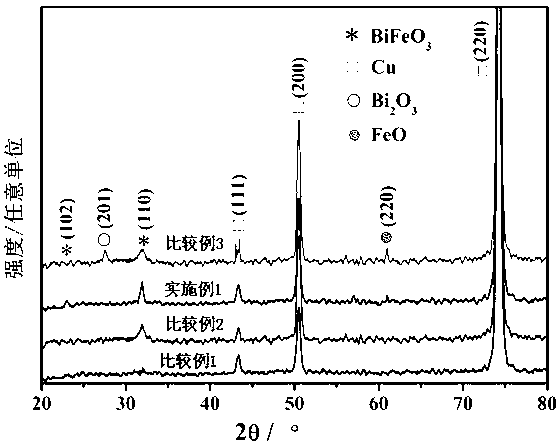

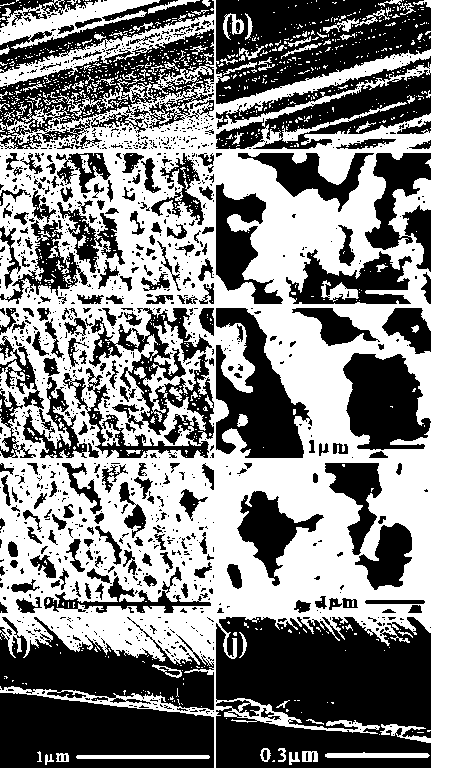

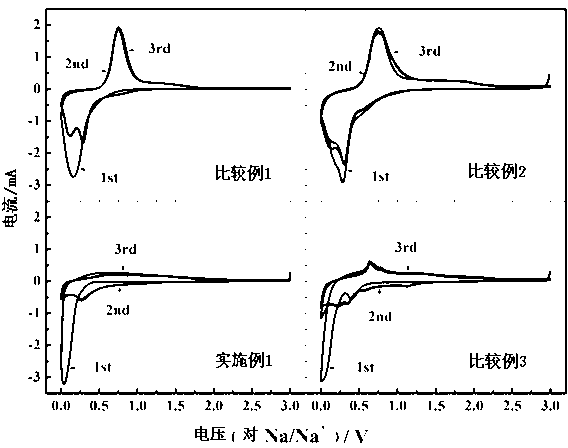

[0028] BiFeO of Example 1 3 The preparation method of sodium ion battery anode material comprises the following steps:

[0029] 1) BiFeO was prepared by conventional high-temperature solid-state sintering method 3 powder, BiFeO 3 The powder is pressed into a target;

[0030] 2) The pressed BiFeO 3 The target is loaded into the magnetron sputtering chamber;

[0031] 3) Use the copper sheet as the substrate, first wash with dilute hydrochloric acid to remove the oxide layer on the surface of the copper sheet, and then put the copper sheet into the magnetron sputtering chamber;

[0032] 4) Vacuumize the magnetron sputtering chamber and fill it with argon gas at a pressure of 1.0Pa, and deposit BiFeO on the copper sheet by magnetron sputtering method 3 Thin film, the deposition rate is 0.08 nm / s, and the deposition thickness is 300 nm;

[0033] 5) will deposit the BiFeO 3 The copper sheet of the film is vacuumed at 8.5×10 -4 Annealed at 600°C for 1 hour under the vacuum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com