Manufacture method for GaInP/GaAs/InGaAsP/InGaAs four-junction cascading solar battery

A production method and technology of solar cells, which are applied in the fields of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the peeling process, increasing the cost of the battery, low mechanical strength, etc., achieving high photoelectric conversion efficiency, improving mechanical strength, and reducing resistance. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

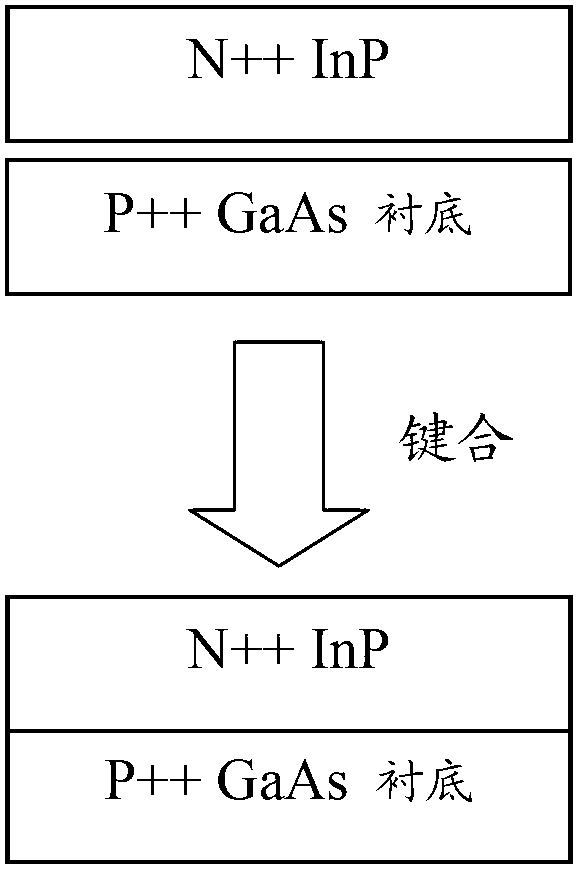

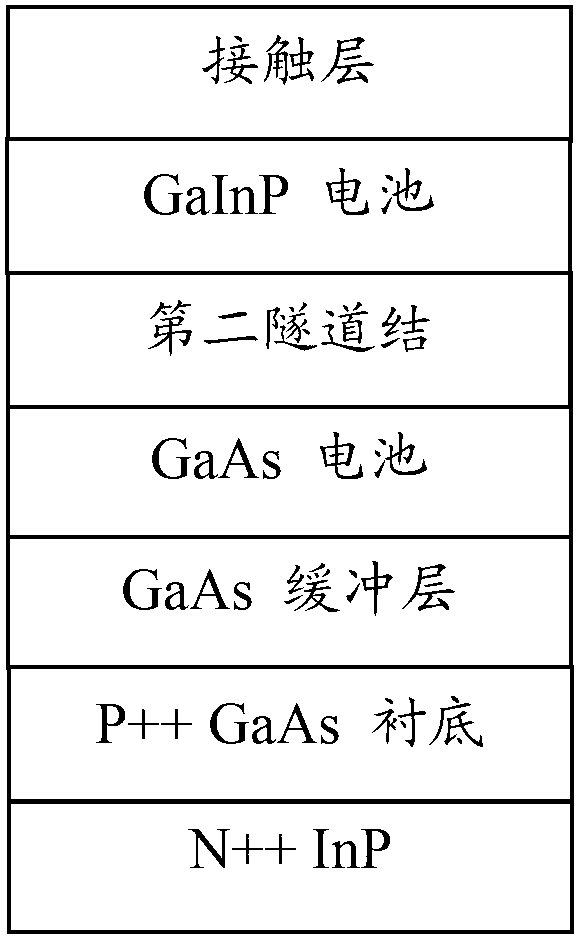

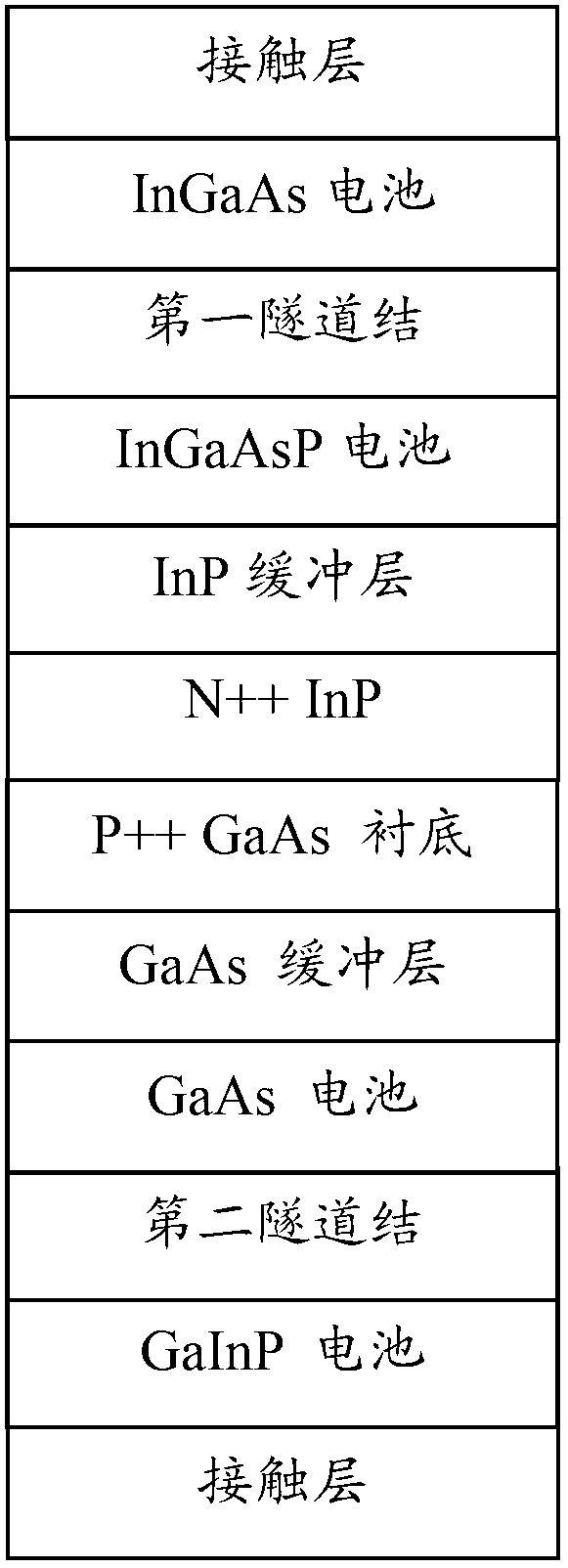

[0023] In view of the fact that the photovoltaic technology represented by the InGaP / (In)GaAs / Ge triple junction tandem solar cells in the existing technology still cannot achieve the best match with the solar spectrum, and the production of monolithic cascading triple junction and above solar energy Due to the objective difficulty of lattice mismatch between semiconductor materials in batteries, the embodiment of the present invention proposes a method for fabricating a GaAs-supported four-junction tandem solar cell, which inherits the relatively high and stable photoelectric conversion efficiency of previous two-junction tandem solar cells. , On the basis of long life, four-junction monolithic high-efficiency solar cells are prepared to obtain high voltage and low current output, thereby effectively reducing the resistance loss in ultra-high concentrating solar cells and achieving high photoelectric conversion efficiency.

[0024] Specifically, an embodiment of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com