Soft starter of direct-current motor and soft starting method thereof

A technology of soft starter and DC motor, which is applied in the field of power conversion and motor control, and can solve the problems of damaged charger, large impact of backup battery pack, electric shock adhesion, etc., and achieves small influence of temperature rise, small power loss, and small fluctuation of starting current , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

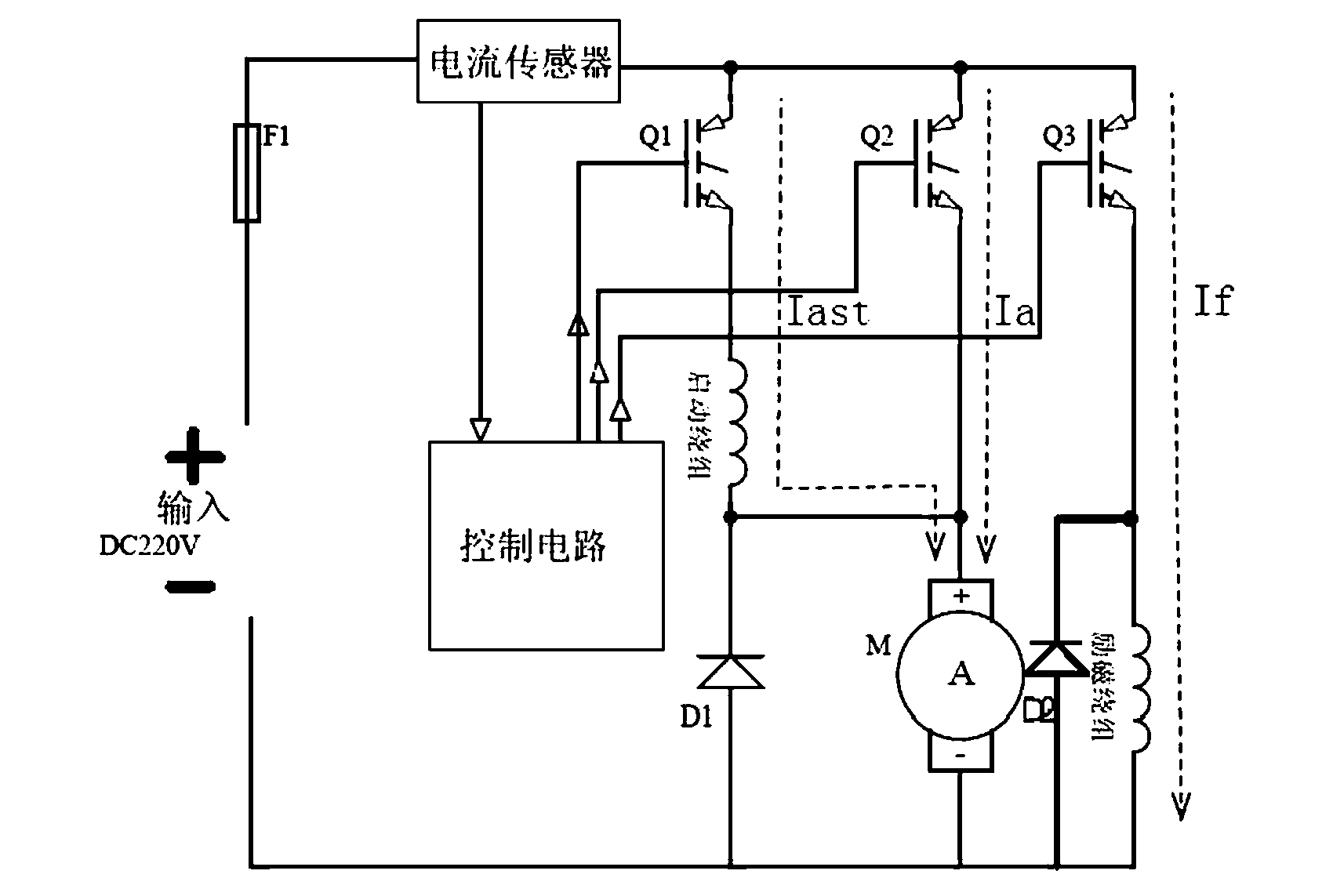

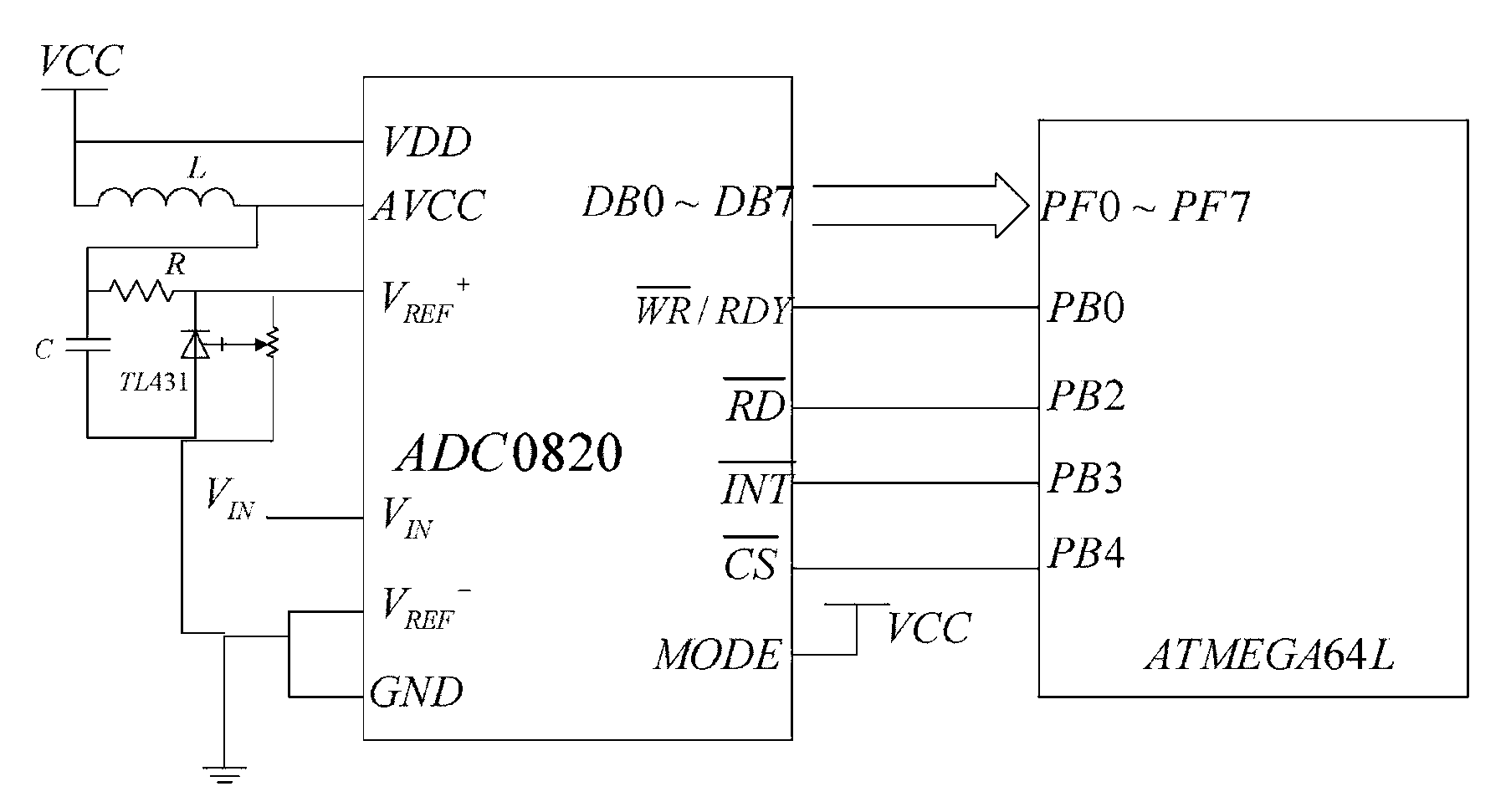

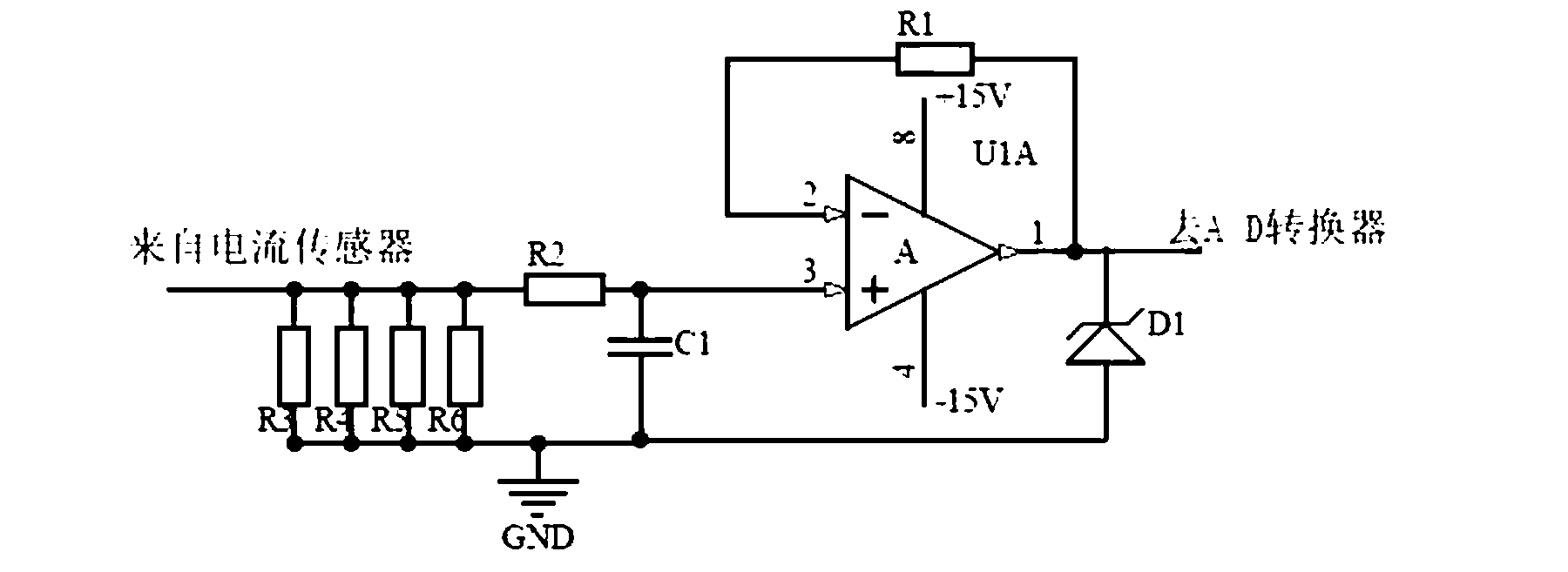

[0035] As shown in the figure, the DC motor soft starter includes a current detection unit, a single-chip microcomputer, a liquid crystal display module, an IGBT drive module and an IGBT module; the current detection unit includes a current sensor and an A / D conversion module; the current signal of the main circuit is passed through The current sensor processing and the conversion of the A / D conversion module are sent to the single-chip microcomputer; the output ports of the single-chip microcomputer are respectively connected to the input ports of the liquid crystal display module and the IGBT drive module; the output port of the IGBT drive module is connected to the motor through the IGBT module Pivot M input port; the IGBT drive module is used to drive the IGBT module and realize the start-up operation of the system by switching the state of the start-up winding.

[0036] In the case of DC power supply, the invention uses a high-performance single-chip microcomputer as the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com