Plastic cellular board and production method

A technology of plastic honeycomb panels and plastic honeycombs, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problem of low mechanical properties, easy degumming at the junction of honeycomb core and panel, strength and rigidity of honeycomb panels , stability constraints and other issues, to achieve stable product quality, high production efficiency, and strengthen the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

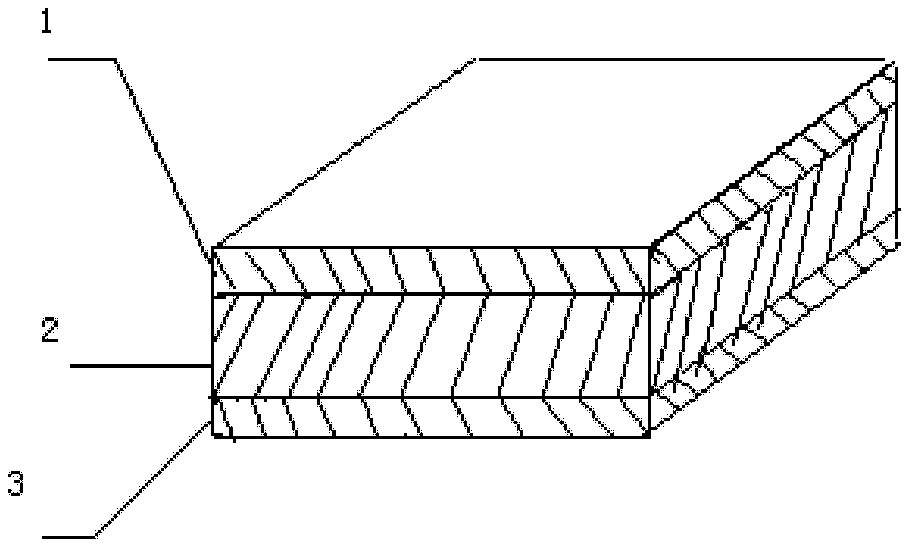

[0019] The following combination figure 1 To further illustrate the present invention, a plastic honeycomb panel includes an upper panel 1, a plastic honeycomb core 2 and a lower panel 3, the upper and lower panels are PP plastic panels, and the plastic honeycomb core is made of PP material. Among them, the thickness of the upper panel is 1mm, the thickness of the lower panel is 1mm, and the thickness of the plastic honeycomb core is 15mm. The upper panel, the honeycomb core, and the lower panel are bonded into a three-layer structure by hot-melting. The temperature is set at 120°C. The pressure is set according to the line bonding between the honeycomb cores and the "T"-shaped bonding between the honeycomb core and the panel. The heating and pressing time is 18 minutes, during which a three-layer decorative material is formed by melting the material itself and curing under pressure.

Embodiment 2

[0021] A plastic honeycomb panel comprises upper and lower panels and a plastic honeycomb core, the upper and lower panels are PP non-woven fabric panels, and the plastic honeycomb core is made of PP material. Among them, the thickness of the upper and lower panels is 0.1 mm, the thickness of the plastic honeycomb core is 1 mm, the temperature is set at 124 ° C, and the pressure is set according to the line bonding between the honeycomb cores and the "T" shape bonding between the honeycomb core and the non-woven fabric. The heating time is 15 minutes, during which a three-layer structure decorative material formed by melting and pressurizing the material itself is used.

Embodiment 3

[0023] A plastic honeycomb panel comprises an upper panel, a lower panel and a plastic honeycomb core, wherein the material of the upper panel and the lower panel is a PC plastic panel, and the material of the plastic honeycomb core is a PC material. The thickness of the upper panel is 4mm, the thickness of the lower panel is 4mm, the thickness of the plastic honeycomb core is 50mm, the temperature is set at 124°C, and the pressure is set according to the line bonding between the honeycomb cores and the "T"-shaped bonding between the honeycomb core and the panel , The heating time is 20 minutes, during which the three-layer structure decorative material is formed by melting and pressurizing the material itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com