Method for extraction of unsaturated fatty acid from oil-containing microalgae and preparation of aviation fuels

A technology of unsaturated fatty acids and aviation fuels, which is applied in the field of comprehensive utilization of oil-containing microalgae, which can solve problems such as poor stability, low calorific value of bio-oil, and industrial application limitations, and achieve high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

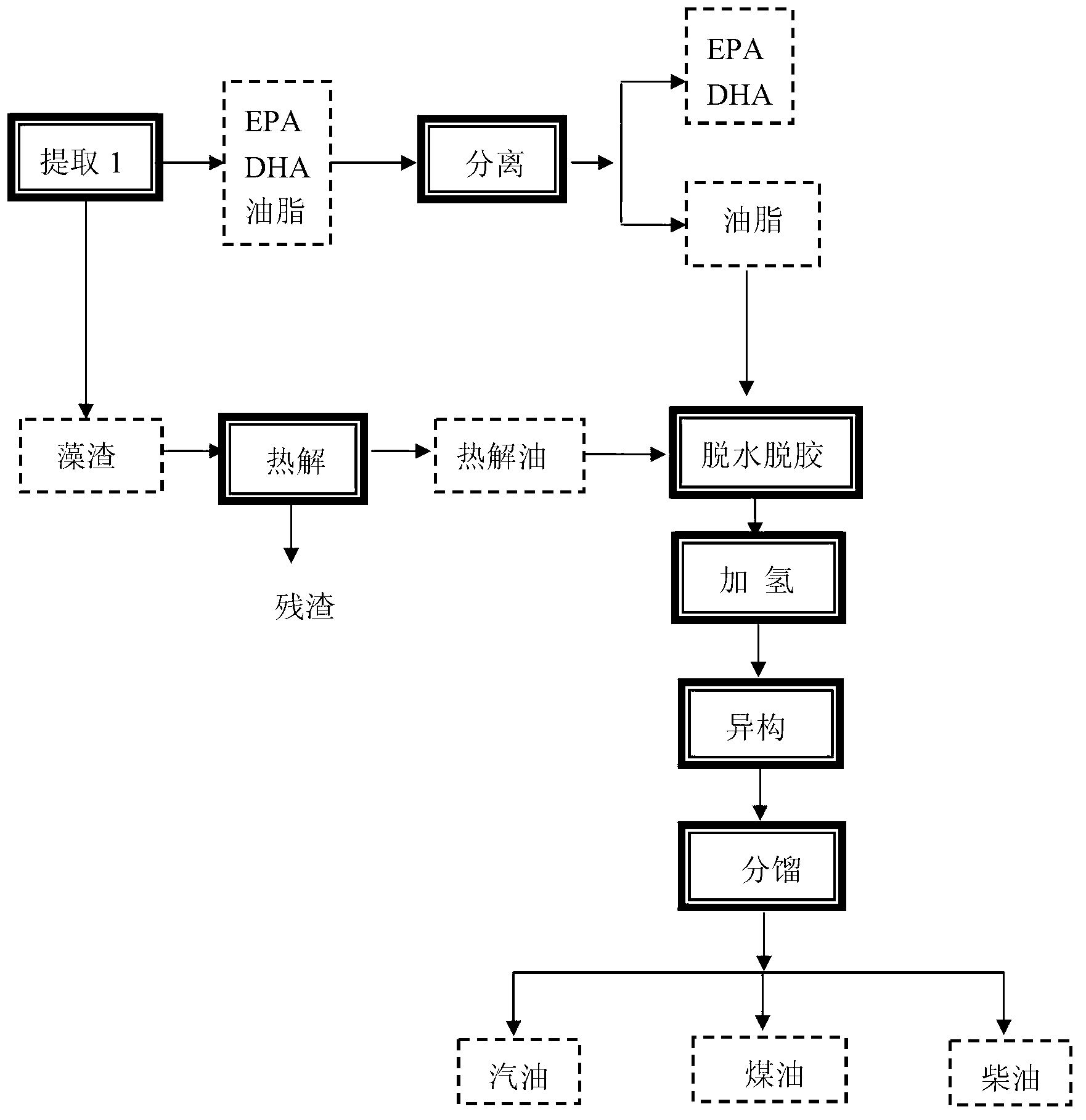

[0046] A kind of oil-containing microalgae extracts DHA and EPA coupling and prepares aviation fuel method, such as figure 1 The system shown includes:

[0047] 1. Extract oil, separate and purify EPA and DHA: adopt supercritical extraction system with additional rectification column. Add the microalgae dry powder into the ethyl acetate entrainer at a ratio of 1:0.6-0.8, mix well and carry out CO 2 Supercritical extraction, supercritical extraction pressure 25-35MPa, temperature 35-45°C, CO 2 The consumption is 150-250ml / g, the extracted mixed oil is sent to the rectification column for separation and enrichment, the rectification pressure is controlled at 11.0-15.0MPa, the rectification temperature gradient is 40-80°C, CO 2 Consumption is 200-300mL / g. Under this process condition, the extraction rate of EPA and DHA can reach 80-95%, and the total extraction rate of oil is 70-90%.

[0048] 2. Pyrolysis of algae residue: after oil extraction, algae residue is mixed with MCM-...

Embodiment 2

[0051] A method for extracting unsaturated fatty acid from oil-containing microalgae and preparing aviation fuel. Such as figure 1 , including the following steps:

[0052] 1. Extract oil, separate and purify EPA and DHA: Add ethanol or ethyl acetate entrainer to microalgae dry powder at a ratio of 1:0.5-1.0, mix well and conduct CO 2 Supercritical extraction, supercritical extraction pressure 30-35MPa, temperature 38-42°C, CO 2 The consumption is 170-250ml / g, the extracted mixed oil is sent to the rectification column for separation and enrichment, the rectification pressure is controlled at 11.0-15.0MPa, the rectification temperature gradient is 40-80°C, CO 2 The consumption is 200-300mL / g. Under this process condition, the extraction rate of EPA and DHA can reach 75-95%, and the total extraction rate of oil is 70-90%.

[0053] 2. Pyrolysis of algae residue: after oil extraction, algae residue is mixed with MCM-41 or HZSM-5 at a mass ratio of 2-4:1, in a fluidized bed rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com