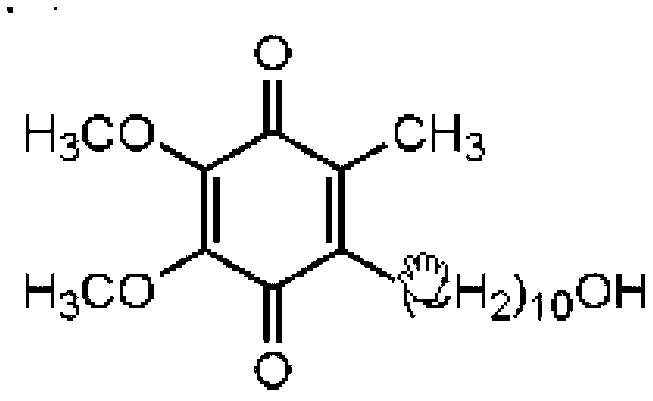

A complex coacervation - spray drying method for preparing idebenone microcapsules

A spray-drying and idebenone technology, applied in the field of preparing microcapsules, can solve the problems of easily causing oxidation, fragile wall membranes of microcapsules, short shelf life, etc. The effect of onset time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] After mixing 1% sodium alginate and 1% gelatin at a weight ratio of 1:1 to form a composite wall material solution, add the core material IDBN powder according to the core wall mass ratio of 1:3, mix and stir evenly, and then homogeneously emulsify for 5 minutes to obtain an emulsion, and then Put the emulsion at a feed temperature of 70°C, an inlet air temperature of 170°C, and an air flow rate of 30m 3 / h under the condition of spray-drying to powder, that is, IDBN microcapsules, the inclusion rate of 82.5%.

Embodiment 2

[0062] After mixing 1% sodium alginate and 2% gelatin at a weight ratio of 1:2 to form a composite wall material solution, add core material IDBN powder at a core-wall mass ratio of 1:1, mix and stir evenly, and homogeneously emulsify for 5 minutes to obtain an emulsion, then Put the emulsion at a feed temperature of 60°C, an inlet air temperature of 160°C, and an air flow rate of 20m 3 / h under the condition of spray-drying into powder, that is, IDBN microcapsules, the inclusion rate of 84.3%.

Embodiment 3

[0064] After mixing 1% sodium alginate and 2.5% gelatin at a weight ratio of 1:2.5 to form a composite wall material solution, add core material IDBN powder at a core-wall mass ratio of 1:2, mix and stir evenly, and then homogeneously emulsify for 5 minutes to obtain an emulsion. Then the emulsion is heated at a feed temperature of 70°C, an inlet air temperature of 170°C, and an air flow rate of 30m 3 / h under the condition of spray-drying to powder, that is, IDBN microcapsules, the inclusion rate of 86.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com