Die and method for semi-solid extrusion thixotropy of degradable magnesium alloy microtubes

A semi-solid extrusion and thixoforming technology, which is applied in the field of forming medical metal materials, can solve the problems of poor mechanical properties of polymer stents, undeveloped manufacturing process and manufacturing equipment, and high manufacturing difficulty, so as to achieve small thermal deformation , Precise molding, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

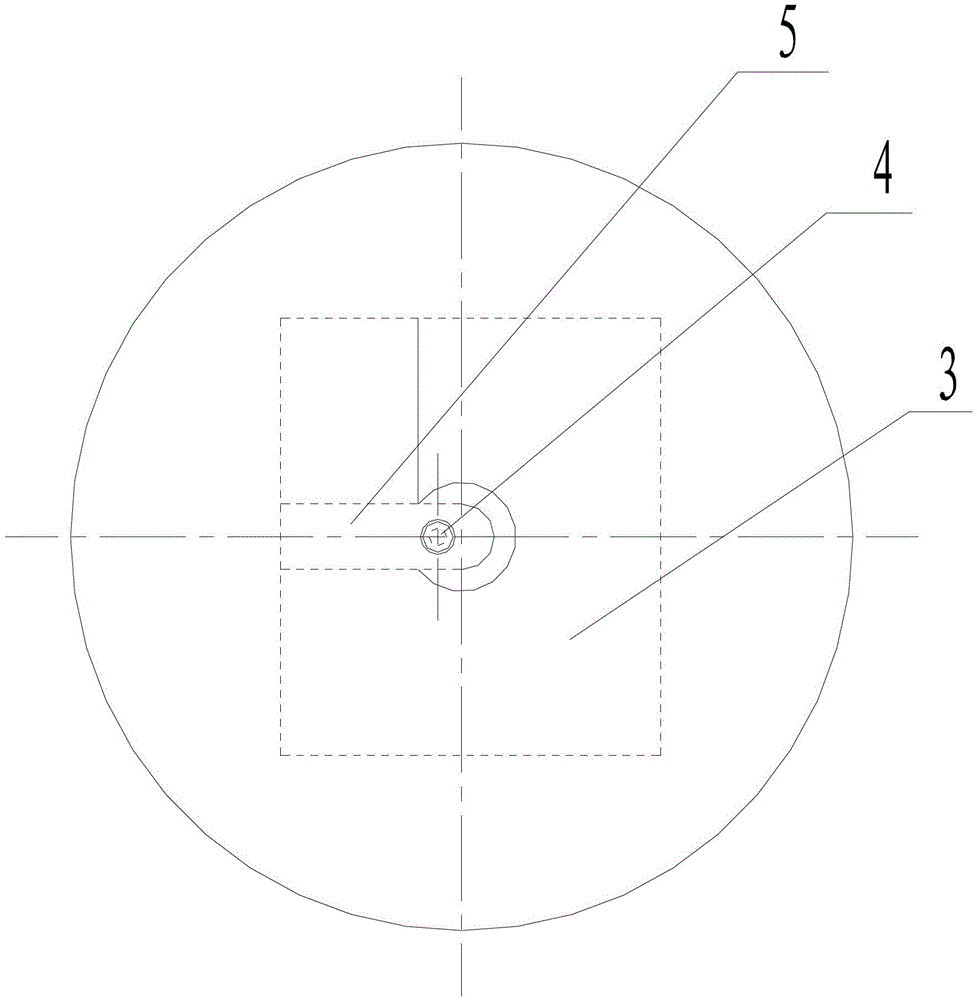

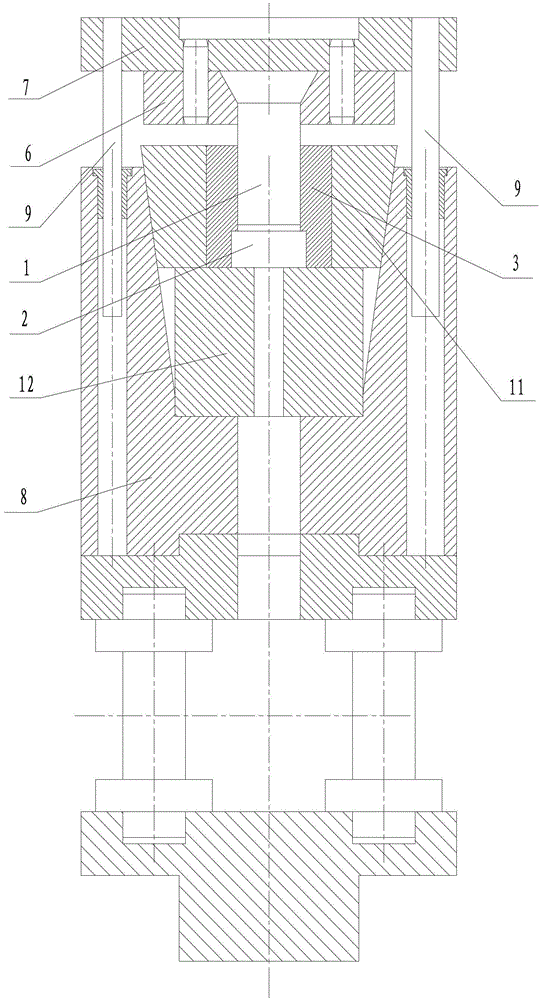

[0030] In this embodiment, a semi-solid extrusion thixotropic molding die of a degradable magnesium alloy microtube, such as image 3 As shown, it includes a matching punch 1 and a die 2, the die is fixed on the bottom of the extrusion cylinder 3, and the punch is arranged on the top of the extrusion cylinder, as figure 2 As shown, a core rod 4 and a core rod fixing plate 5 are also provided between the punch and the die, the core rod is embedded in the core rod fixing plate, the bottom of the core rod extends into the die, and the bottom of the punch and the core rod fixing plate The tops are connected, and one side of the core rod fixing plate extends into the space in the middle of the extrusion cylinder, such as image 3 As shown, the core rod fixing plate and the space in the middle of the extrusion barrel form a notched annular space.

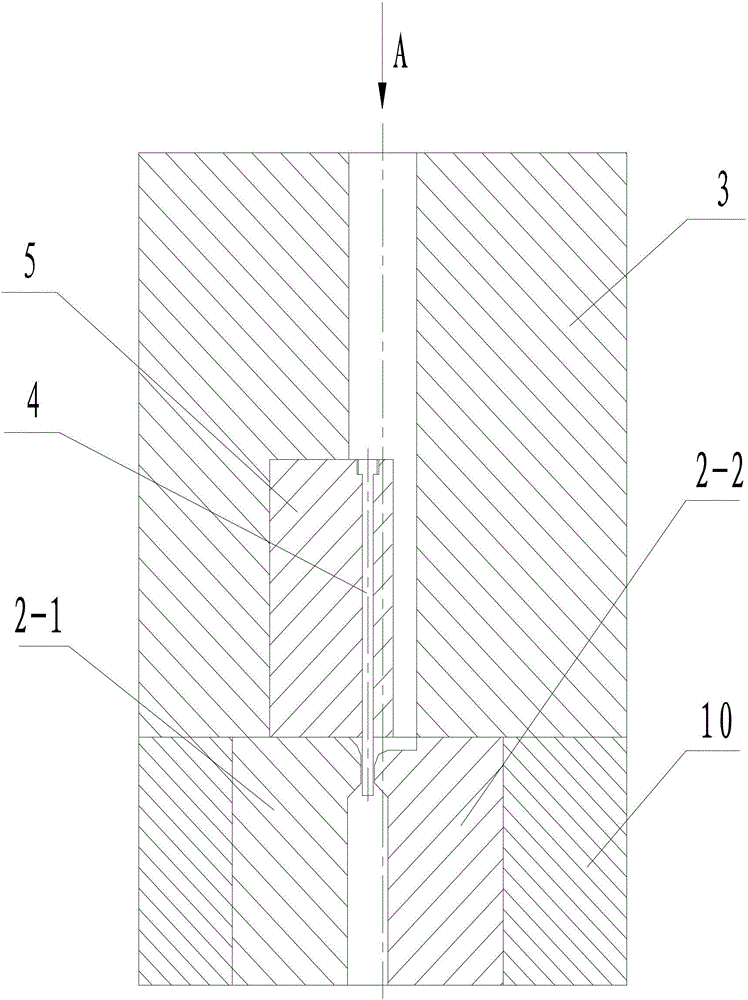

[0031] Such as figure 1 As shown, the die includes a left die 2-1 and a right die 2-2, a bottle-shaped space is formed between the le...

Embodiment 2

[0038] In this example, a degradable magnesium alloy microtube with an inner diameter of 1.5 mm and a thickness of 0.1 mm is prepared by the mold described in Example 1, and its forming method includes the following steps:

[0039] (1) The magnesium alloy material of ZK60 (40%)+WE43 (60%) is made into powder by ball milling, and the powder particle size is 0.01~0.1mm, and argon gas as an inert protective gas is added during the ball milling process to prevent the powder from oxidation;

[0040] (2) Evenly coating graphite as a lubricant on the inner surface of the extrusion cylinder, the inner surface of the die, the outer surface of the punch, the side surface of the core rod fixing plate located in the extrusion cylinder and the outer surface of the core rod;

[0041] (3) Put the powder into the extrusion barrel, and adjust the parameters of the pressure equipment, such as the pressure is 80-100KN, the speed is automatic, and the temperature is 580-650°C;

[0042] (4) Heat t...

Embodiment 3

[0047] In this example, a degradable magnesium alloy microtube with an inner diameter of 2.0mm and a thickness of 0.1mm is prepared by the mold described in Example 1, and its forming method includes the following steps:

[0048] (1) The magnesium alloy material of MB1 (40%)+MB15 (60%) is made into powder by ball milling, the powder particle size is 0.01~0.1mm, and argon gas is added as an inert protective gas during the ball milling process to prevent powder oxidation;

[0049] (2) Evenly coating graphite as a lubricant on the inner surface of the extrusion cylinder, the inner surface of the die, the outer surface of the punch, the side surface of the core rod fixing plate located in the extrusion cylinder and the outer surface of the core rod;

[0050] (3) Put the powder into the extrusion cylinder, and adjust the parameters of the pressure equipment, such as the pressure is 100-120KN, the speed is automatic, and the temperature is 500-550°C;

[0051] (4) Heat the mold in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com