Hydraulic device with pneumatic booster fuel tank for oil-hydraulic hybrid electric bus

A pneumatic pressurization and oil-liquid mixing technology, which is applied to hybrid vehicles, fluid hybrid vehicles, power plants, etc., can solve the problems of reducing the output torque of hydraulic motors and slowing down the pressure boost of oil pumps, so as to ensure output torque, hydraulic pressure, etc. The effect of small vibration and fast boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

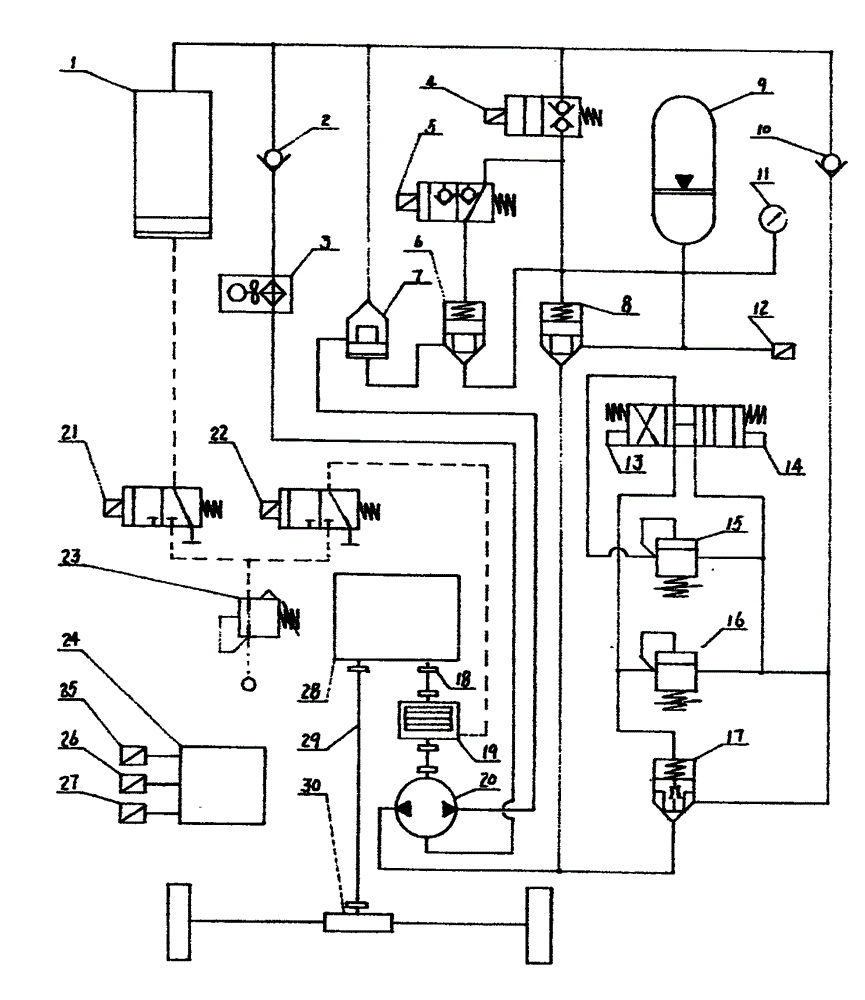

[0015] Such as figure 1 Shown:

[0016] The present invention mainly includes: pneumatic pressurized oil tank 1, oil return cut-off valve 2, oil return cooler 3, unloading control valve 4, energy release control valve 5, energy release valve 6, oil inlet stroke control valve 7, energy storage control valve Valve 8, capsule accumulator 9, main oil return cut-off valve 10, pressure display 11, pressure sensor 12, retarder I control valve 13, retarder II control valve 14, first retarder pressure regulating valve 15, second Slow pressure regulating valve 16, Oil return control valve with throttle 17, Coupling 18, Rear mounted power take-off with friction clutch 19, Inclined shaft axial plunger pump 20, Pneumatic pressurized oil tank control valve 21 , friction clutch control valve 22, air pressure regulating valve 23, electric program controller 24, brake sensor 25, accelerator sensor 26, vehicle speed sensor 27, bus gearbox 28, bus drive shaft 29, bus rear axle 30.

[0017]1. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com