A kind of latex fiberboard water retention treatment agent and its preparation method and water retention method

A technology of latex fiberboard and water treatment agent, which is applied in fiber raw material treatment, fiberboard, textiles and papermaking, etc., and can solve the problems of easy fracture in product processing, small balance moisture of latex fiberboard, bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Based on the total mass fraction of 100%, add 3.5kg of industrial glycerin (industrial pure), 3kg of zinc chloride (industrial pure), 3.5kg of carboxylated styrene-butadiene latex (50% solid content) and 990kg of water into a container In a plastic tank of 1 ton of liquid, mix and stir evenly to obtain a water-retaining treatment agent for latex fiberboard.

[0019] 2. Under the conditions of sizing temperature of 70°C and sizing pressure of 0.1MPa, apply the above-mentioned latex fiberboard water retention treatment agent on the surface of the latex fiberboard by surface sizing, so that the latex fiberboard water retention treatment agent can penetrate evenly And stay on latex fibreboard.

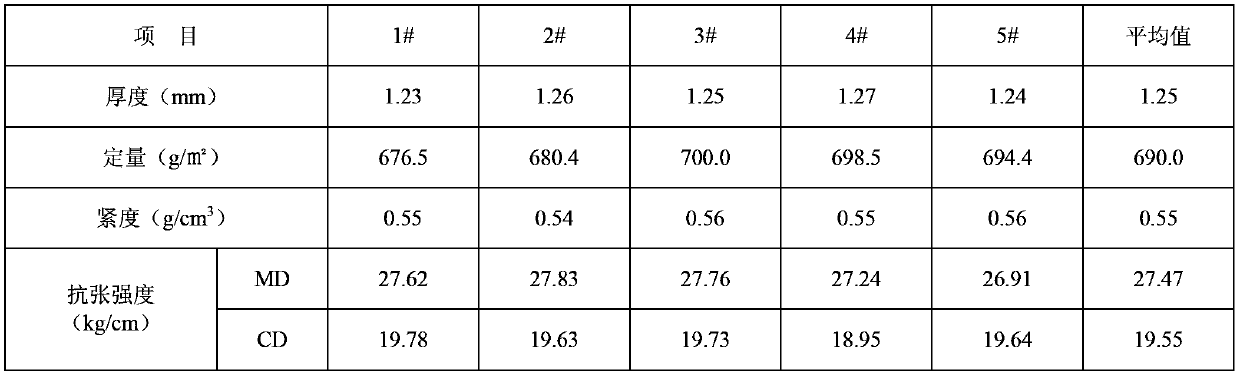

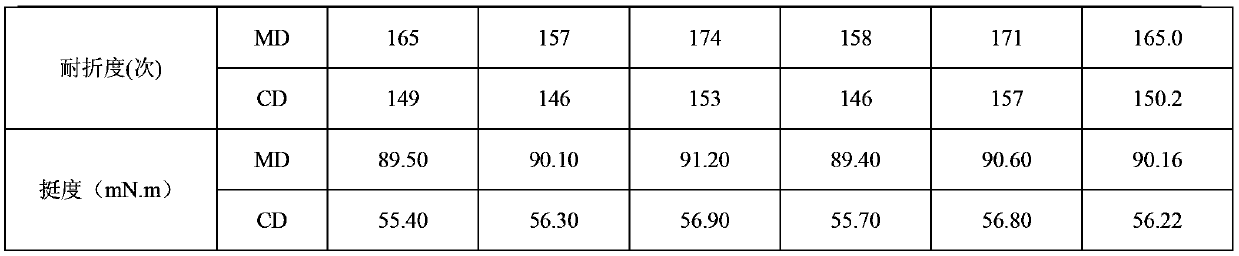

[0020] 3. Take 10 samples from the 1.25mm latex fiberboard treated with the latex fiberboard water-retaining treatment agent prepared in this example, detect the on-site moisture content of 5 samples, and place the other 5 samples for 48 hours for balance treatment.

[0021] 4. ...

Embodiment 2

[0035] 1. According to the total mass fraction of 100%, add 7kg of industrial glycerin (industrial pure), 6kg of zinc chloride (industrial pure), 7kg of carboxylated styrene-butadiene latex (solid content is 50%) and 980kg of water in turn into a container that can hold 1 ton In a liquid glue tank, mix and stir evenly to obtain a water-retaining treatment agent for latex fiberboard.

[0036] 2. Under the conditions of sizing temperature of 90°C and sizing pressure of 0.3MPa, apply the above-mentioned latex fiberboard water retention treatment agent on the surface of the latex fiberboard by surface sizing, so that the latex fiberboard water retention treatment agent can penetrate evenly And stay on latex fibreboard.

[0037] 3. Take 10 samples from the 1.25mm latex fiberboard treated with the latex fiberboard water-retaining treatment agent prepared in this example, detect the on-site moisture content of 5 samples, and place the other 5 samples for 48 hours for balance treatmen...

Embodiment 3

[0057] 1. According to the total mass fraction of 100%, add 5kg of industrial glycerin (industrial pure), 5kg of zinc chloride (industrial pure), 5kg of carboxylated styrene-butadiene latex (solid content is 50%) and 985kg of water in turn into a container that can hold 1 ton In a liquid glue tank, mix and stir evenly to obtain a water-retaining treatment agent for latex fiberboard.

[0058] 2. Under the conditions of sizing temperature of 80°C and sizing pressure of 0.2MPa, apply the above-mentioned latex fiberboard water-retaining treatment agent on the surface of the latex fiberboard by surface sizing, so that the latex fiberboard water-retaining treatment agent can penetrate evenly And stay on latex fibreboard.

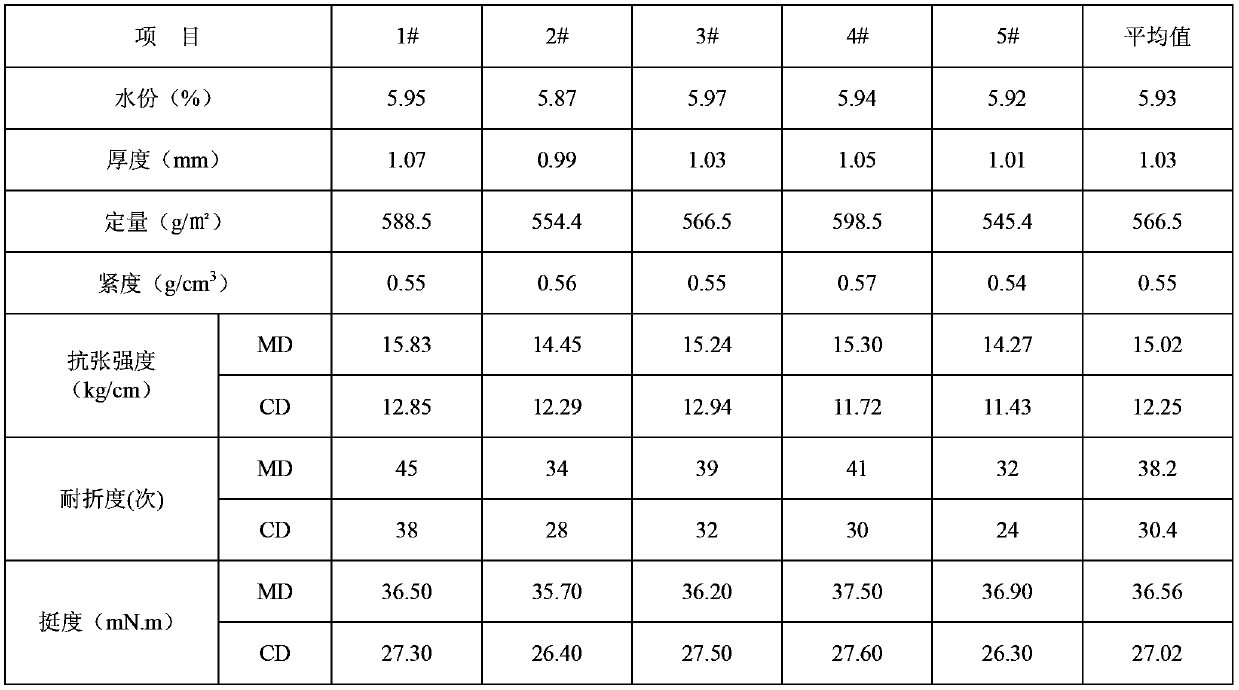

[0059] 3. Take 10 samples from the 1.25mm latex fiberboard treated with the latex fiberboard water-retaining treatment agent prepared in this example, detect the on-site moisture content of 5 samples, and place the other 5 samples for 48 hours for balance treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com