An etching method for HgCdTe material with low damage and high uniformity

A mercury cadmium telluride, low-damage technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, electrical components, etc., can solve the problems of surface atom chemical ratio imbalance, lower device performance, material type inversion, etc., to achieve Good I-V characteristics, excellent chip performance, and low damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

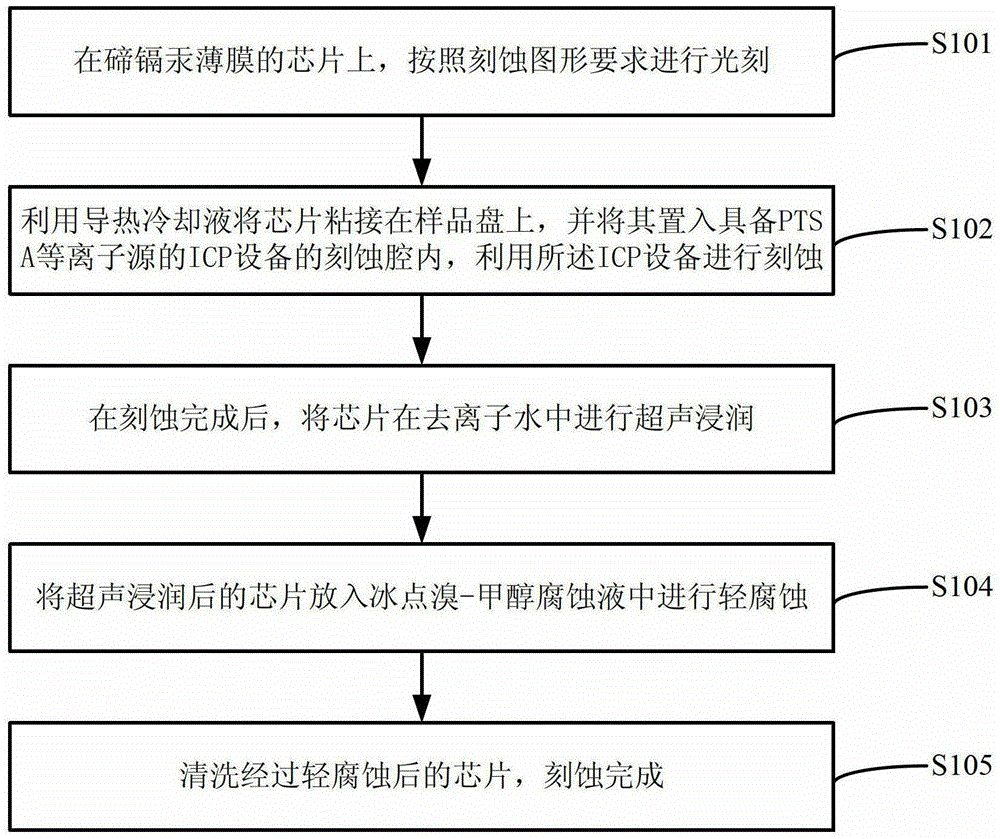

[0024] An embodiment of the present invention provides an etching method for HgCdTe material with low damage and high uniformity, such as figure 1 shown, including the following steps:

[0025] Step S101, performing photolithography on the HgCdTe thin film chip according to the etching pattern requirements;

[0026] Step S102, using heat conduction cooling liquid to bond the chip on the sample tray, and placing it into the etching chamber of the ICP equipment equipped with a PTSA plasma source, and using the ICP equipment to perform etching;

[0027] Step S103, after the etching is completed, ultrasonically infiltrate the chip in deionized water;

[0028] Preferably, in this step, the ultrasonic frequency used for ultrasonic infiltration is 20kHz-80kHz, and the power is 50W-150W.

[0029] Preferably, in this step, the time for ultrasonic infiltration is 3 minutes to 6 minutes.

[0030] Step S104, putting the ultrasonically wetted chip into a freezing point bromine-methanol ...

Embodiment 2

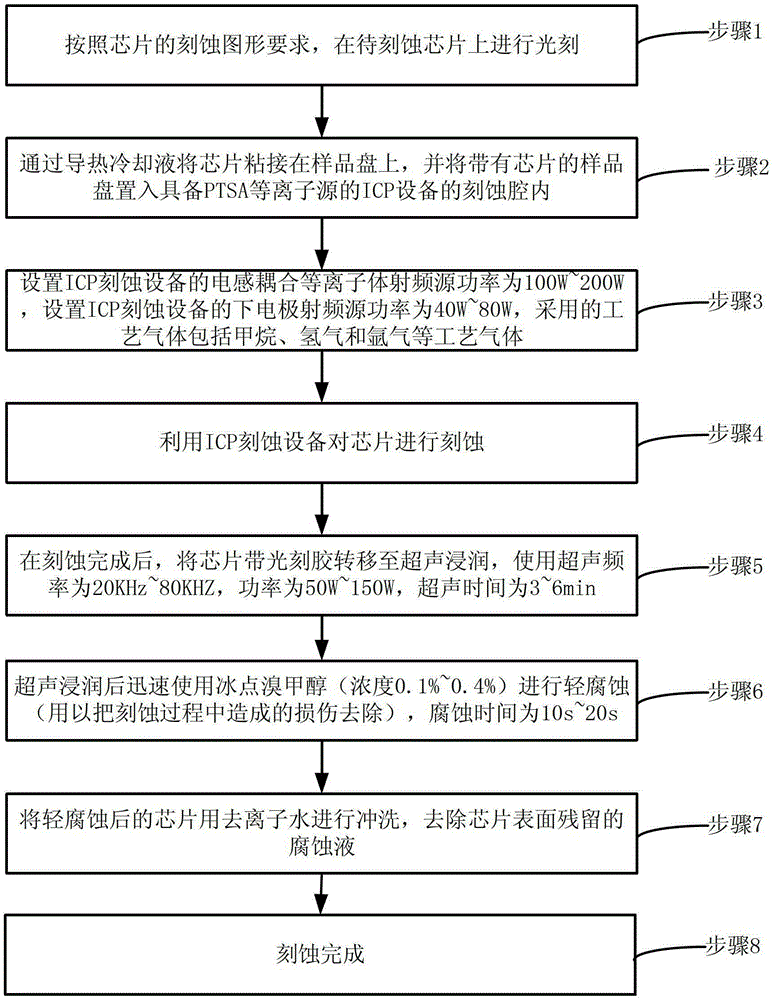

[0036] An embodiment of the present invention provides an etching method for HgCdTe material with low damage and high uniformity. The basic principle of this embodiment is the same as that of Embodiment 1, and it is a further detailed elaboration of the method described in Embodiment 1 in conjunction with the accompanying drawings. .

[0037] The method described in the embodiment of the present invention mainly incorporates the following technologies:

[0038] (1) Chip etching is performed using ICP (Inductively Coupled Plasma Etching) etching equipment using a PTSA (Plant Triple Helix Antenna) type ion source. Among them, the PTSA-type ion source has the ability to provide more efficient RF coupling and generate higher-density plasma under the condition of low RF power. The uniformity of etching is reduced due to temperature inhomogeneity; at the same time, the plasma generated by the PTSA ion source has lower energy (<20eV), which can better reduce the damage in the etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com