Cordyceps sinensis soft capsule and preparation method thereof

A technology of Cordyceps sinensis and soft capsules, which is applied in the field of Cordyceps sinensis soft capsules and its preparation, can solve the problems of loss and easy destruction of active ingredients, and achieve the effects of increasing content, reducing dosage, and improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

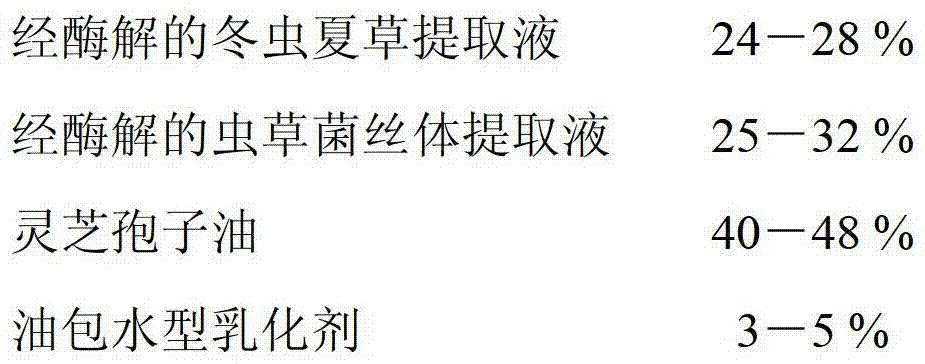

[0041] A kind of Cordyceps sinensis soft capsule, the content of this soft capsule is made up of following components by weight percentage:

[0042]

[0043] The preparation method of above-mentioned Cordyceps sinensis soft capsule, carries out as follows:

[0044] (1) fully enzymatically hydrolyze the Cordyceps sinensis extract and the Cordyceps mycelium extract: adjust the pH of the extract to 4.5, and the temperature to 50° C., add enzyme for enzymolysis for 1 hour, and then inactivate the enzyme;

[0045] (2) Production of soft capsules: control temperature at 25±2°C, humidity at 45%±5%, including batching, mixing, emulsification, sol, and pill pressing, proceed as follows:

[0046] (1) Fully mix the Cordyceps sinensis extract and Cordyceps mycelium extract that require water-in-oil and Ganoderma lucidum spore oil according to the formula quantity, and the mixing time is 20 minutes;

[0047] (2) Add an emulsifier that can emulsify into a water-in-oil emulsion according...

Embodiment 2

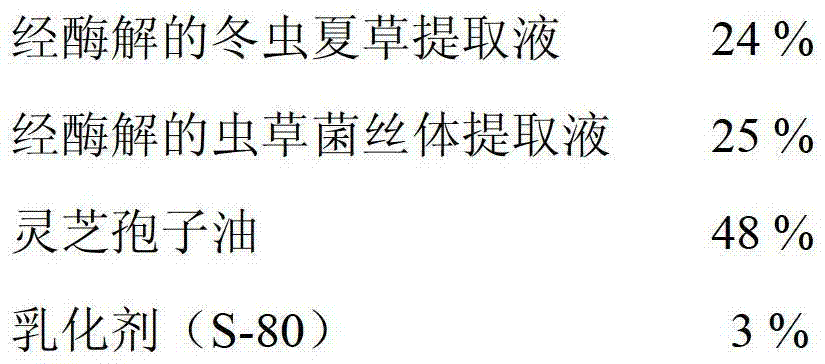

[0055] A kind of Cordyceps sinensis soft capsule, the content of this soft capsule is made up of following components by weight percentage:

[0056]

[0057] The preparation method of above-mentioned Cordyceps sinensis soft capsule, carries out as follows:

[0058] (1) Fully enzymolyze the Cordyceps sinensis extract and the Cordyceps mycelium extract: adjust the pH of the extract to 4, the temperature to 55° C., add enzyme to enzymolyze for 1.2 hours, and then inactivate the enzyme;

[0059] (2) Production of soft capsules: control temperature at 25±2°C, humidity at 45%±5%, including batching, mixing, emulsification, sol, and pill pressing, proceed as follows:

[0060] (1) Fully mix the Cordyceps sinensis extract and Cordyceps mycelium extract that require water-in-oil and Ganoderma lucidum spore oil according to the formula quantity, and the mixing time is 30 minutes;

[0061] (2) Add an emulsifier that can emulsify into a water-in-oil emulsion according to the formula, s...

Embodiment 3

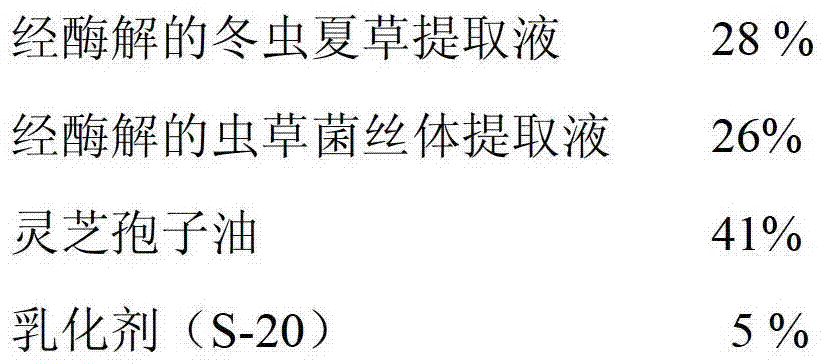

[0069] A kind of Cordyceps sinensis soft capsule, the content of this soft capsule is made up of following components by weight percentage:

[0070]

[0071] The preparation method of above-mentioned Cordyceps sinensis soft capsule, carries out as follows:

[0072] (1) Fully enzymolyze the Cordyceps sinensis extract and the Cordyceps mycelium extract: adjust the pH of the extract to 5, the temperature to 45° C., add enzyme to enzymolyze for 1.5 hours, and then inactivate the enzyme;

[0073] (2) Production of soft capsules: control temperature at 25±2°C, humidity at 45%±5%, including batching, mixing, emulsification, sol, and pill pressing, proceed as follows:

[0074] (1) Fully mix the Cordyceps sinensis extract and Cordyceps mycelium extract that require water-in-oil and Ganoderma lucidum spore oil according to the formula quantity, and the mixing time is 40 minutes;

[0075] (2) Add an emulsifier that can emulsify into a water-in-oil emulsion according to the formula, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com