Dry-process fine continuous desulfurization device and method for CFB (Circulating Fluidized Bed) boiler

A desulfurization device and dry method technology, applied in the field of boiler desulfurization, can solve the problems of difficult control of bed temperature desulfurizer quality and failure to meet emission requirements, so as to improve the utilization rate and desulfurization efficiency of desulfurizer, meet environmental protection emission requirements, and invest in operation The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

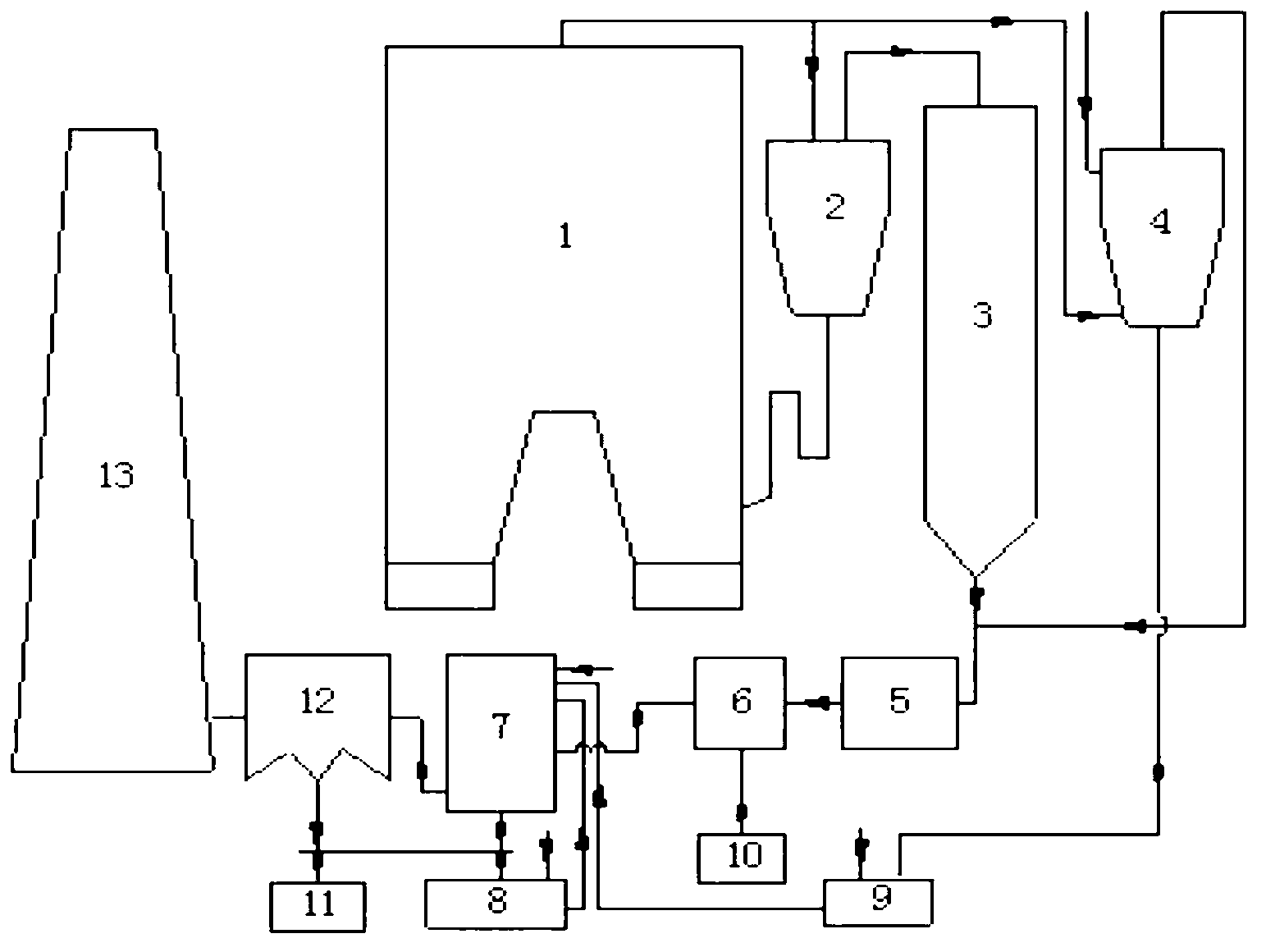

[0015] Such as figure 1 As shown: a dry fine continuous desulfurization device for CFB boilers in this embodiment, including a chimney 13, and others: CFB boiler furnace 1, cyclone separator 2, tail flue 3, limestone calciner 4, Air preheater 5, pre-dust collector 6, ash store a10, tail flue gas semi-dry desulfurization system; wherein: the tail flue gas semi-dry desulfurization system is composed of SO 2 Absorber 7, circulating liquid tank 8, digestion tank 9, ash store b11 bag filter 12; the CFB boiler furnace 1 is respectively connected to the cyclone separator 2 and the limestone calciner 4 through the flue gas pipeline; the cyclone separator 2 The bottom of the cyclone separator 2 is connected to the furnace 1 through the return pipe, and the top of the cyclone separator 2 is connected to the tail flue 3 through the flue gas pipe; the limestone powder is transported to the limestone calciner 4 through the powder conveying pipe, and the bottom of the limestone calciner 4 i...

Embodiment 2

[0021] Such as figure 1 As shown: a dry fine continuous desulfurization device for CFB boilers in this embodiment, including a chimney 13, and others: CFB boiler furnace 1, cyclone separator 2, tail flue 3, limestone calciner 4, Air preheater 5, pre-dust collector 6, ash store a10, tail flue gas semi-dry desulfurization system; wherein: the tail flue gas semi-dry desulfurization system is composed of SO 2 Absorber 7, circulating liquid tank 8, digestion tank 9, ash store b11 bag filter 12; the CFB boiler furnace 1 is respectively connected to the cyclone separator 2 and the limestone calciner 4 through the flue gas pipeline; the cyclone separator 2 The bottom of the cyclone separator 2 is connected to the furnace 1 through the return pipe, and the top of the cyclone separator 2 is connected to the tail flue 3 through the flue gas pipe; the limestone powder is transported to the limestone calciner 4 through the powder conveying pipe, and the bottom of the limestone calciner 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com