Preparation method of SiO2 nanorod/CdS

A nanorod, attapulgite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unseen SiO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

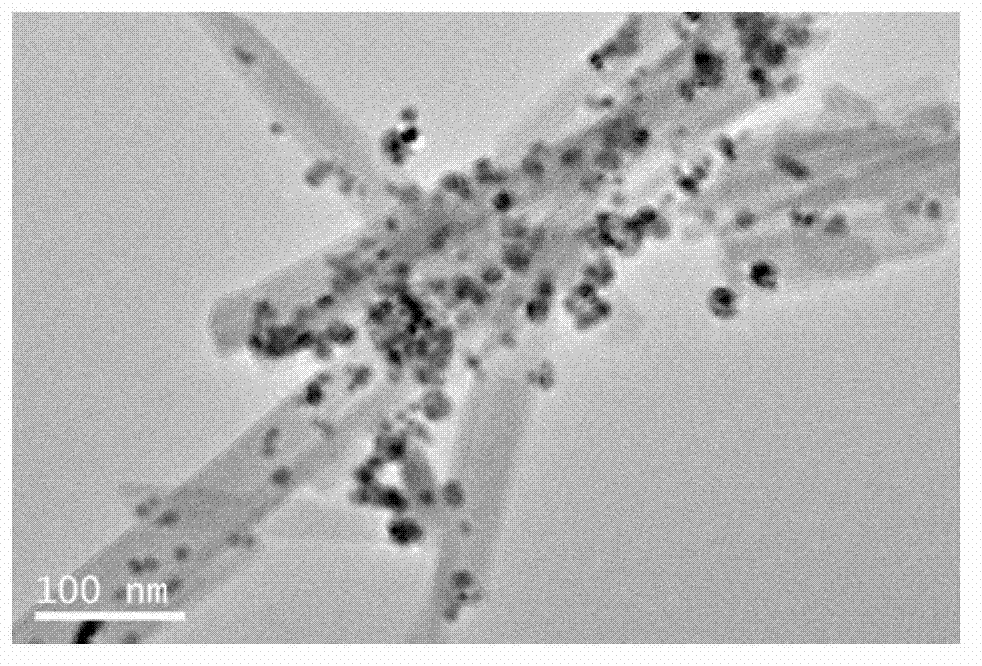

[0017] Example 1: Take 4.0000 g of attapulgite clay, dissolve it in 200 mL of hydrochloric acid solution, heat to reflux for 4 hours, and the heating temperature is 120°C. The active SiO was then evaporated and dried in vacuo 2 . Then take 1.0000g SiO 2 Grind and move into the PTFE lining, and add the template agent EDTA, CdCl in sequence 2 、Na 2 S, the masses are 1.2000g, 1.3960g, 0.6536g respectively, heated at 120℃ for 2h. Finally, wash and dry to obtain a composite material. The X-ray powder diffraction experiment was carried out on the obtained sample, and its morphology and structure were observed under a transmission electron microscope.

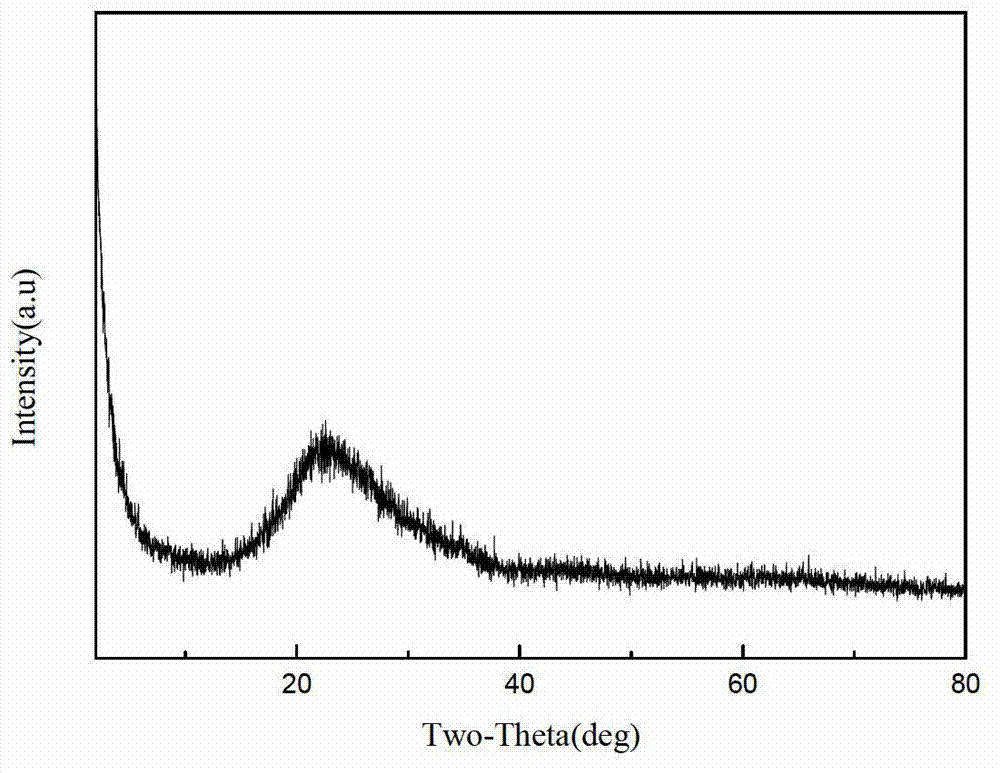

[0018] According to the SiO that the process parameter of embodiment 1 makes 2 The XRD patterns of the nanorods are as figure 1 shown. In the prepared SiO 2 There is obvious SiO in the map 2 The characteristic diffraction peaks indicate that the attapulgite clay was acidified to produce SiO 2 Nano stave.

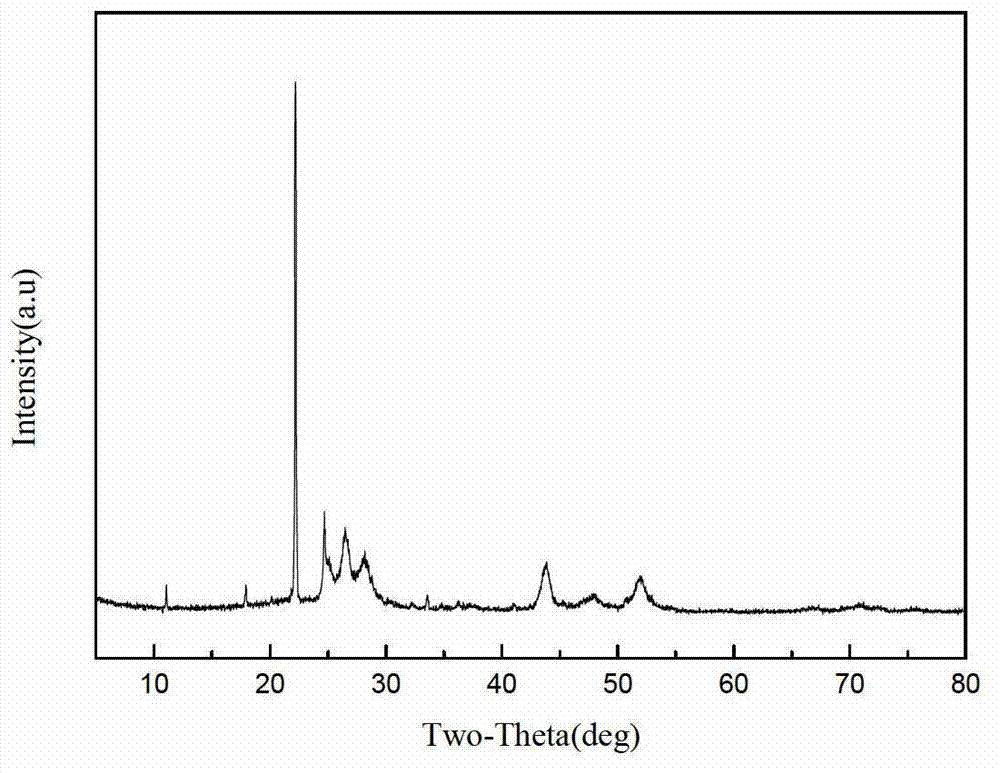

[0019] SiO 2 XR...

Embodiment 2

[0020] Example 2: Change the attapulgite clay to 4.0000g, dissolve it in 200mL of hydrochloric acid solution, heat to reflux for 4 hours, and the heating temperature is 120°C. The active SiO was then evaporated and dried in vacuo 2 . Then take 1.0000g SiO 2 Grind and move into the PTFE lining, and add the template agent PVP, CdCl in sequence 2 、Na 2 S, the masses are 1.0000g, 1.2690g, 0.5401g respectively, heated at 100℃ for 2h. Finally, wash and dry to obtain a composite material. Subsequent detection was as in Example 1.

Embodiment 3

[0021] Example 3: 4.0000 g of attapulgite clay was taken, dissolved in 200 mL of hydrochloric acid solution, and heated to reflux for 4 hours at a heating temperature of 120°C. The active SiO was then evaporated and dried in vacuo 2 . Then take 1.0000g SiO 2 Grind and move into the PTFE lining, and add template agent P123, CdCl in sequence 2 、Na 2 S, the masses are 1.5000g, 2.5380g, 1.2964g respectively, heated at 130℃ for 3h. Finally, wash and dry to obtain a composite material. Subsequent detection was as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com