Preparation method of over-sprayed paint water treatment disinfectant in airplane coating technology

A coating process and water treatment technology, applied in the direction of neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of poor stability of melamine and formaldehyde resin solutions, easy stratification, and secondary pollution of water bodies To achieve the effects of protecting the working environment and the health of operators, strong electricity neutralization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of modified polyether GP330: In a closed reactor, add 100g of polyether GP330, then add 5g of hydrophobic silica, stir well, raise the temperature to 80°C for 3 hours, discharge after cooling, and set aside.

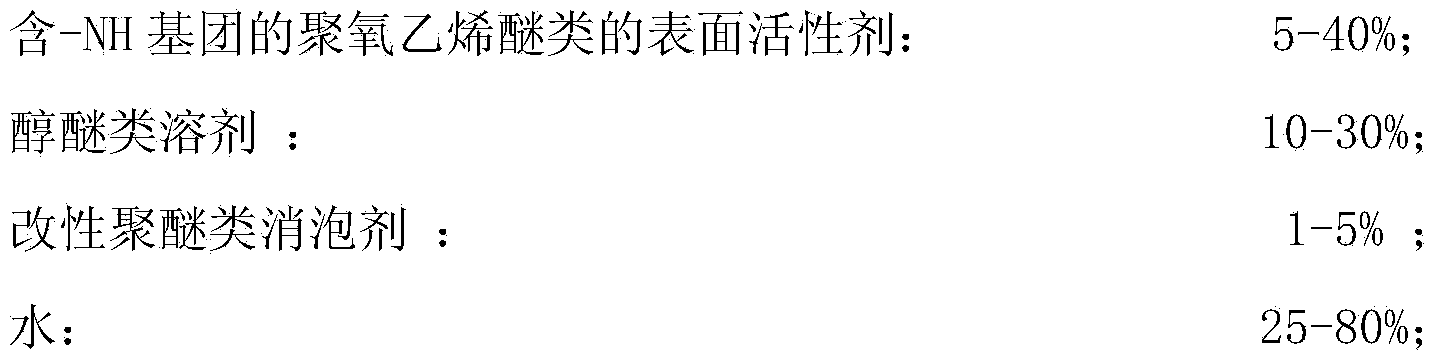

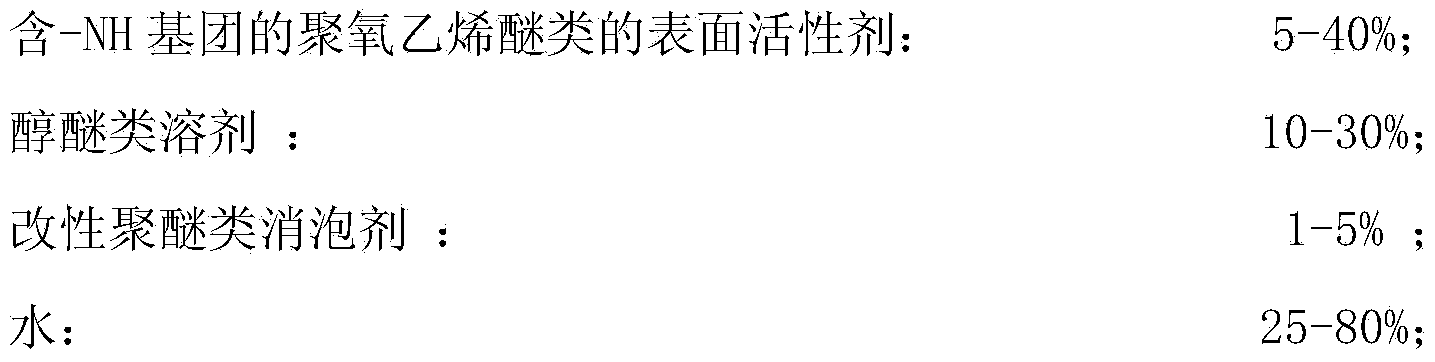

[0019] Preparation of anti-viscosity agent DMC-A: Add 79g of water to the reaction bottle, add 10g of dodecylamine polyoxyethylene (10) ether, 10g of ethylene glycol methyl ether, and 1g of modified polyether GP330 in sequence, stir for 2 hours, and fully Mix, let stand and discharge.

Embodiment 2

[0021] Preparation of flocculant DMC-B: First add 1000g of water and 0.2g of aluminum sulfate into the reaction bottle. After stirring and dissolving, add 1g of anionic polyacrylamide with a molecular weight of 10 million and a degree of hydrolysis of 25. After stirring and dissolving completely, put material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com