A preparation method of unfired ceramsite with Fenton-like reaction properties

A technology of Fenton reaction and ceramsite, applied in the field of technology and application, can solve the problems of heavy metal pollution, low utilization rate of hydrogen peroxide, inability to play a catalytic role, etc., and achieves great application and promotion value. The effect of easy solid-liquid separation and convenient recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

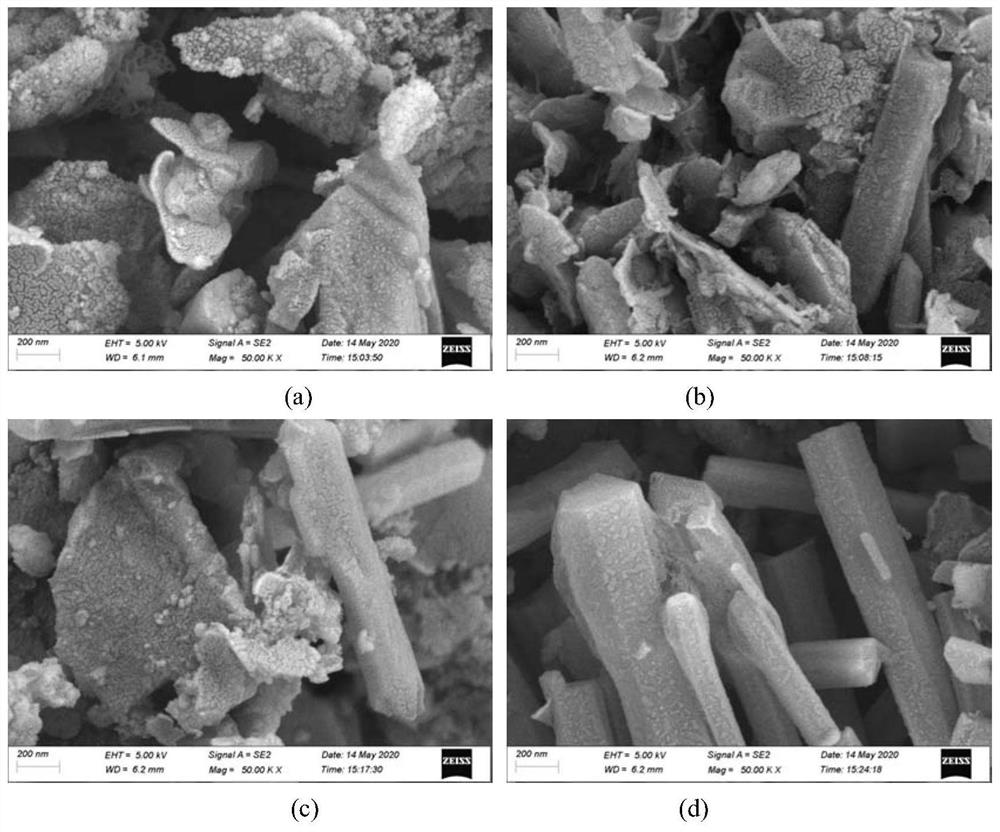

Embodiment 1

[0044] The ratio of fly ash, sludge, cement, oyster shell, diatomite and sepiolite is 15:15:20:20:30:10, adding 5% sodium silicate binder and 1% Calcium oxide activator, mix homogeneously, obtain mixed raw material; Get mixed raw material 5kg, in small disc granulator, be that the ferrous sulfate solution of 10wt% is sprayed mixed raw material and it is humidified to it with concentration, treat that the size of ball reaches 10 Stop at ~15mm and discharge to produce spherical raw meal, and accurately measure the volume of ferrous sulfate solution used to facilitate subsequent calculation of H 2 o 2 The amount of solution used.

[0045] The spherical raw meal is placed in a steam curing box, first cured at a temperature of 30°C and a humidity of 85% for 6 hours, and then heated to 60°C and maintained at a humidity of 80% for 6 hours. Then move it into a constant temperature drying oven at 50°C to dry for 6 hours, and cool naturally to obtain an unfired ceramsite with Fenton-l...

Embodiment 2

[0048] The ratio of fly ash, sludge, cement, activated clay, attapulgite, and oyster shells is 20:20:30:10:30:20, and the aforementioned 4% starch binder and 2% calcium sulfate are added to stimulate agent, mix evenly to obtain the mixed raw material; take 5kg of the mixed raw material, in a small disc granulator, spray the mixed raw material with a concentration of 15wt% ferrous chloride solution to humidify it, until the size of the ball reaches 10-15mm stop and discharge material at any time to obtain spherical raw meal, and accurately measure the volume of ferrous sulfate solution used for the convenience of subsequent calculation of H 2 o 2 The amount of solution used.

[0049] The spherical raw meal is placed in a steam curing box, first cured at a temperature of 40°C and a humidity of 90% for 5 hours, and then heated to 70°C and maintained at a humidity of 85% for 5 hours. Then move it into a constant temperature drying oven at 60°C to dry for 4 hours, and cool natura...

Embodiment 3

[0052] The ratio of fly ash, sludge, cement, green zeolite, bentonite, and oyster shells is 30:10:25:15:20:30, adding 3% of the aforementioned mass of sodium silicate binder and 3% of calcium oxide to stimulate agent, mix evenly to obtain the mixed raw material; take 5kg of the mixed raw material, in a small disc granulator, spray the mixed raw material with a concentration of 20wt% ferrous sulfate solution to humidify it, and when the size of the ball reaches 10-15mm Stop the machine and discharge the material to prepare spherical raw meal, and accurately measure the volume of the ferrous sulfate solution used for the convenience of subsequent calculation of H 2 o 2 The amount of solution used.

[0053] The spherical raw meal is placed in a steam curing box, first cured at a temperature of 45°C and a humidity of 95% for 4 hours, and then heated to 80°C and maintained at a humidity of 90% for 4 hours. Then move it into a constant temperature drying oven at 60°C to dry for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com