Method for preparing salvianolic acid A

A technology of salvianolic acid and acidic substances, applied in the field of preparing high-purity salvianolic acid A, can solve the problems of low extraction rate and low purity of salvianolic acid A, reduce impurity content and purification difficulty, improve conversion rate, and improve The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

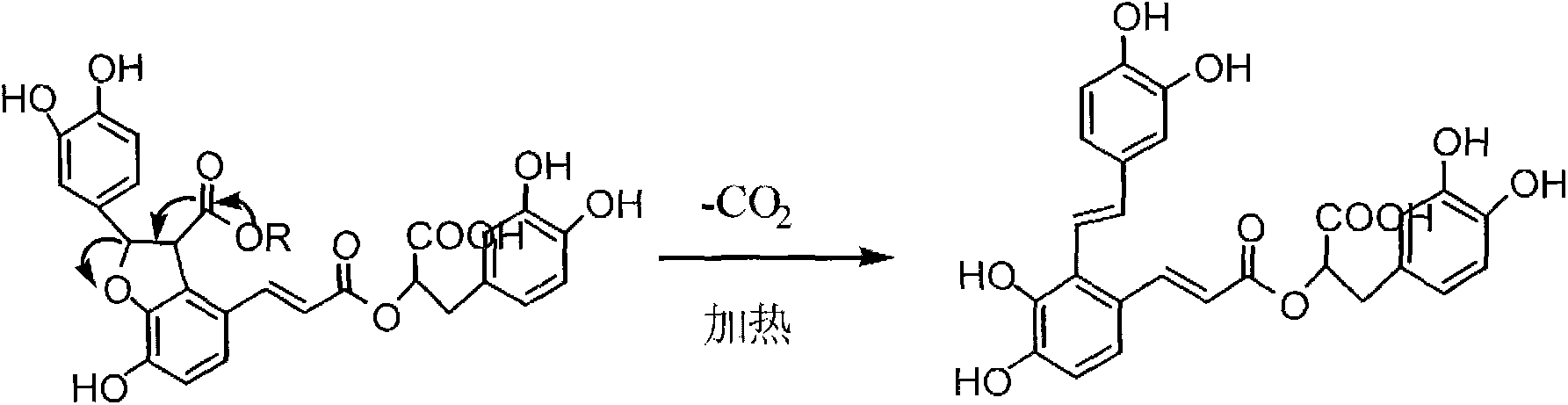

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of method for preparing salvianolic acid A

[0024] A method for preparing salvianolic acid A, comprising the following steps:

[0025] (1) Get the salvianolic acid B extract that the salvianolic acid B content is 2%, take the salvianolic acid B extract weight as a benchmark, add the dimethyl sulfoxide of 7 times of weight parts and dissolve completely, add the acetic acid of 1 times of weight (100% acetic acid concentration), heated at 130° C. for 5 hours, and cooled to obtain a salvianolic acid A enrichment solution;

[0026] (2) The salvianolic acid A enrichment solution obtained in the cooling step (1) is dissolved in water with 3.6 times the weight of the salvianolic acid A enrichment solution, filtered, and the filtrate is separated by HZ841 macroporous resin column chromatography to obtain salvianolic acid a.

[0027] In step (2) of this example, HP-20, XAD-8, HZ801, HZ803, HB16, D1450, HP-20ss or XAD-16 macroporous resin column chromatograp...

Embodiment 2

[0028] Embodiment 2 A kind of method for preparing salvianolic acid A

[0029] A method for preparing salvianolic acid A, comprising the following steps:

[0030] (1) get salvianolic acid B content and be the material containing salvianolic acid B of 10%, add the ethylene glycol of 10 times of weight and dissolve completely, add the acetic acid of 1 times of weight (acetic acid volume concentration is 0.01%), at 110 ℃ Under heating for 5 hours, cooling to obtain the salvianolic acid A enrichment solution;

[0031] (2) The enriched solution of salvianolic acid A obtained in the cooling step (1) was dissolved by adding 5 times the weight of water, filtered, and the filtrate was separated by HP-20 macroporous resin column chromatography to obtain salvianolic acid A.

[0032] In step (2) of this example, XAD-8, HZ801, HZ803, HZ841, HB16, D1450, HP-20ss or XAD-16 macroporous resin column chromatography can also be used for separation.

Embodiment 3

[0033] Embodiment 3 A kind of method for preparing salvianolic acid A

[0034] A method for preparing salvianolic acid A, comprising the following steps:

[0035] (1) Get the salvianolic acid B extract that salvianolic acid B content is 10%, add the dimethyl sulfoxide of 7 times of weight and dissolve completely, add the acetic acid of one time of weight (acetic acid volume concentration is 5%), 112 ℃ of temperature , heated for 5 hours, and cooled to obtain a salvianolic acid A enrichment solution;

[0036] (2) The enriched solution of salvianolic acid A obtained in the cooling step (1) was dissolved by adding 4 times the weight of water, filtered, and the filtrate was separated by HZ841 macroporous resin column chromatography to obtain salvianolic acid A.

[0037] In step (2) of this example, HP-20, XAD-8, HZ801, HZ803, HB16, D1450, HP-20ss or XAD-16 macroporous resin column chromatography can also be used for separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com