Fluorosilicone acrylates copolymer emulsion as well as preparation method and application thereof

A technology of fluorosilicon acrylate and copolymerization emulsion, which is applied in building components, building insulation materials, construction, etc., can solve the problems that cationic acrylates have not been reported, and improve cold resistance, reduce glass transition temperature, and stabilize good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

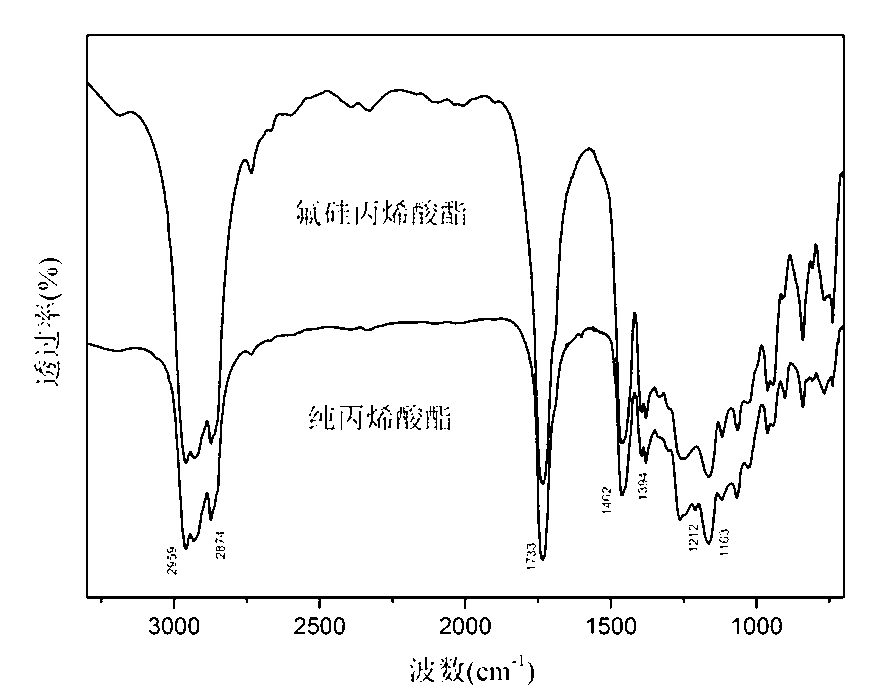

Image

Examples

Embodiment 1

[0025] Emulsion polymerization was carried out in a 500ml four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, and a dropping funnel, and N 2 Protection, 1 / 5 acrylic monomer (n-butyl acrylate + isooctyl acrylate), complex emulsifier (hexadecyltrimethylammonium bromide + fatty alcohol polyoxyethylene ether), initiator ammonium persulfate , added to water, and reacted at 80°C for 0.5h to obtain a slightly blue seed emulsion.

[0026] Mix all the functional monomers vinyltriethoxysiloxane, trifluoropropyltrimethylcyclotrisiloxane and the remaining 4 / 5 acrylic monomers (n-butyl acrylate + isooctyl acrylate) , compound emulsifier (cetyltrimethylammonium bromide + fatty alcohol polyoxyethylene ether), initiator ammonium persulfate, and water are subjected to high-speed shear pre-emulsification for 10 minutes, and then slowly added dropwise to the above seed emulsion. The reaction was carried out at 85° C. for 4 h, and after cooling down, the pH was adj...

Embodiment 2

[0038] Emulsion polymerization was carried out in a 500ml four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, and a dropping funnel, and N 2 Protection, 1 / 5 acrylic monomer (n-butyl acrylate + isooctyl acrylate), complex emulsifier (hexadecyltrimethylammonium bromide + fatty alcohol polyoxyethylene ether), initiator ammonium persulfate , added to water, and reacted at 80°C for 0.5h to obtain a slightly blue seed emulsion.

[0039] Mix all the functional monomers vinyltriethoxysiloxane, trifluoropropyltrimethylcyclotrisiloxane and the remaining 4 / 5 acrylic monomers (n-butyl acrylate + isooctyl acrylate) , compound emulsifier (cetyltrimethylammonium bromide + fatty alcohol polyoxyethylene ether), initiator ammonium persulfate, and water for high-speed shear pre-emulsification for 10 minutes, and then slowly add to the above seed emulsion. The reaction was carried out at 85° C. for 4 h, and after cooling down, the pH was adjusted to 7.5 with ammoni...

Embodiment 3

[0043] Emulsion polymerization was carried out in a 500ml four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, and a dropping funnel, and N 2 Protection, 1 / 5 acrylic monomer (n-butyl acrylate + isooctyl acrylate), complex emulsifier (hexadecyltrimethylammonium bromide + water-based ethoxylated non-ionic fluorocarbon surfactant ), the initiator ammonium persulfate was added into water, and reacted at 80°C for 0.5h to obtain a slightly blue seed emulsion.

[0044] Mix all the functional monomers vinyltriethoxysiloxane, trifluoropropyltrimethylcyclotrisiloxane and the remaining 4 / 5 acrylic monomers (n-butyl acrylate + isooctyl acrylate) , composite emulsifier (hexadecyltrimethylammonium bromide + water-based ethoxylated non-ionic fluorocarbon surfactant), initiator ammonium persulfate, and water for high-speed shear pre-emulsification for 10 minutes, and then slowly land value with In the above seed emulsion. The reaction was carried out at 85° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com