High-performance anthraquinone cobalt blue mixed reactive printing dye

A reactive printing, anthraquinone-based technology, applied in the field of printing dyes, can solve the problems of light brittleness, narrow application range, poor fiber color fastness, etc., and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

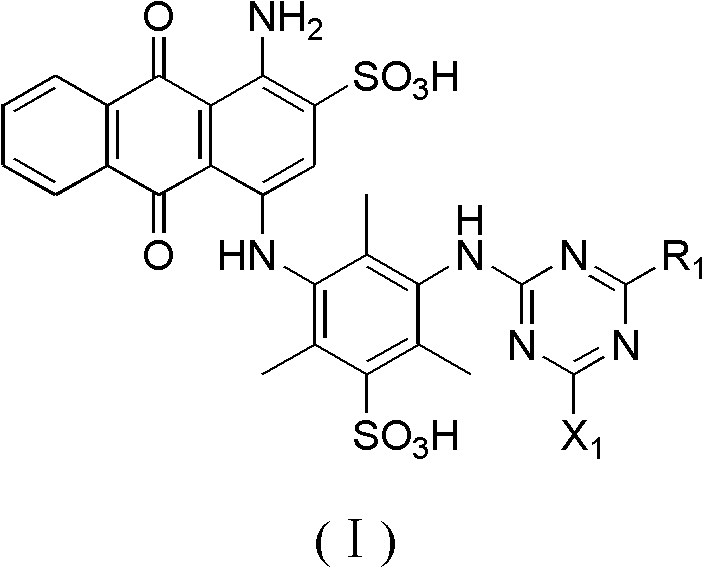

[0072] The preparation of embodiment 1 anthraquinone dye I

[0073] In a 1000 ml beaker, add 100 parts of crushed ice, 50 parts of water, 18.5 parts of cyanuric chloride, 0.1 part of dispersant, stir for 30 to 45 minutes, add 53.2 parts of the dye matrix of general formula I, at pH=5.5~ 6.5. React at a temperature of 8-12°C for 3 hours. After reaching the end point, add 17.3 parts of m-aminobenzenesulfonic acid, raise the temperature to 40-45°C, adjust the pH to 7-7.5 with sodium carbonate, and react for 6 hours. After the pH is stable, it will be At the end point, directly spray dry to obtain the dye I-1.

[0074]

Embodiment 2-5

[0075] The preparation of embodiment 2-5 anthraquinone dyes I-2~I-5

[0076] Compared with Example 1, the only difference is that the m-aminobenzenesulfonic acid in the reaction process is replaced by p-aminobenzenesulfonic acid, anthranilolsulfonic acid, etc., and dyes I-2 to I-5 can be obtained respectively.

[0077]

[0078]

[0079] Only some dyes shown in general formula I have been exemplified here, and those skilled in the art can foresee that different reactants can be used to obtain dyes I with different substituents to finally realize the present invention. repeat.

Embodiment 6-10

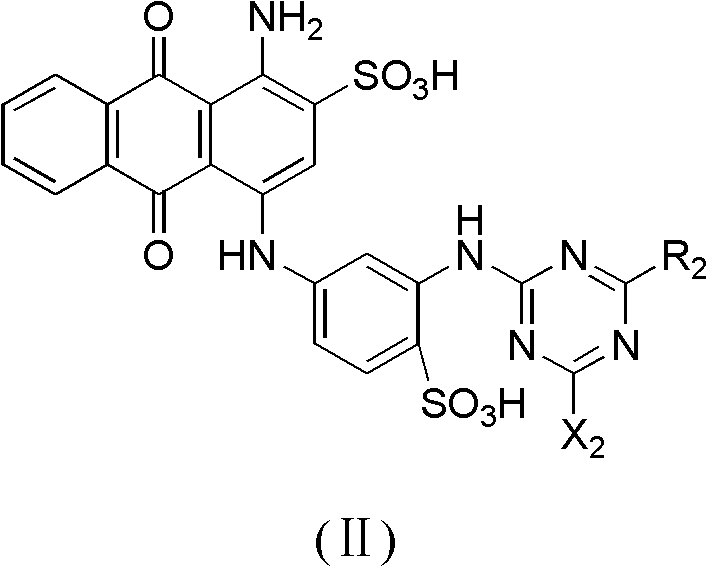

[0080] The preparation of embodiment 6-10 anthraquinone dye II

[0081] In a similar manner to Example 1, the dye precursors of general formula II were used to replace the dye precursors of general formula I to obtain dyes II-1 to II-5.

[0082]

[0083]

[0084] Only some dyes of the general formula II are exemplified here. Those skilled in the art can foresee that different reactants can be used to obtain dyes II with different substituents to finally realize the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com