Electrostatic spinning preparation method for hybrid nanofiber membrane containing P(LLA-CL) and magnesium metal

A nanofiber membrane, metal magnesium technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of weakened tissue functionality, degradation rate hindering the synthesis of new tissue, etc., and achieve novel operation, good application prospects, and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

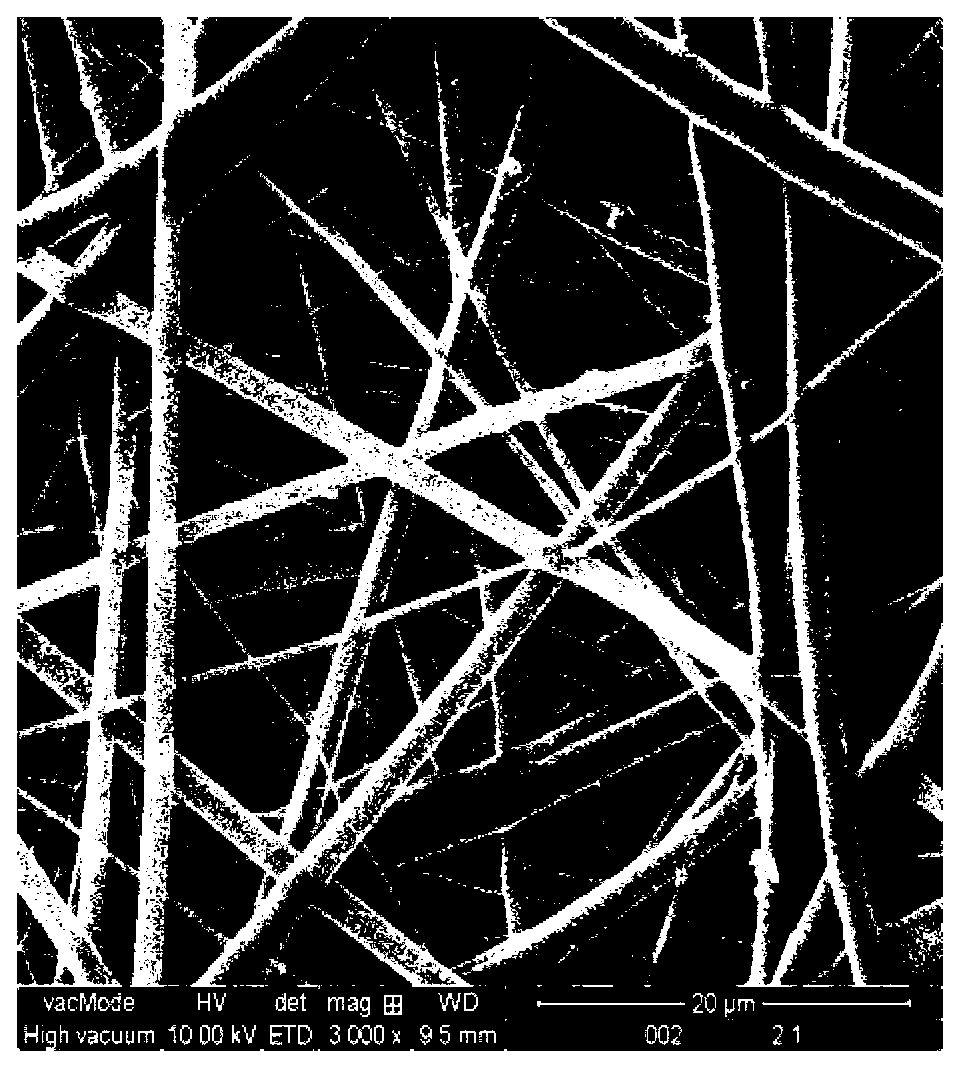

[0019] Weigh 0.4 g of P(LLA-CL) with an electronic analytical balance and dissolve it in 5 ml of hexafluoroisopropanol to obtain a P(LLA-CL) solution with a concentration of 8% (g / ml); weigh it with an electronic analytical balance 0.2 grams of magnesium powder, dissolved in 8% (g / ml) P(LLA-CL) solution, magnetically stirred at room temperature until completely dissolved (the mass ratio of P(LLA-CL) to magnesium powder in the solution is 2:1 ); after dissolving, the solution is an electrospinning solution, the voltage is 16 kV, the advancing speed of the syringe is 1.0 ml / hour, and the receiving distance is 15 cm. The No. 9 needle is selected and accepted by aluminum foil paper to obtain a P( LLA-CL) and metal magnesium powder nano-hybrid fiber membrane.

Embodiment 2

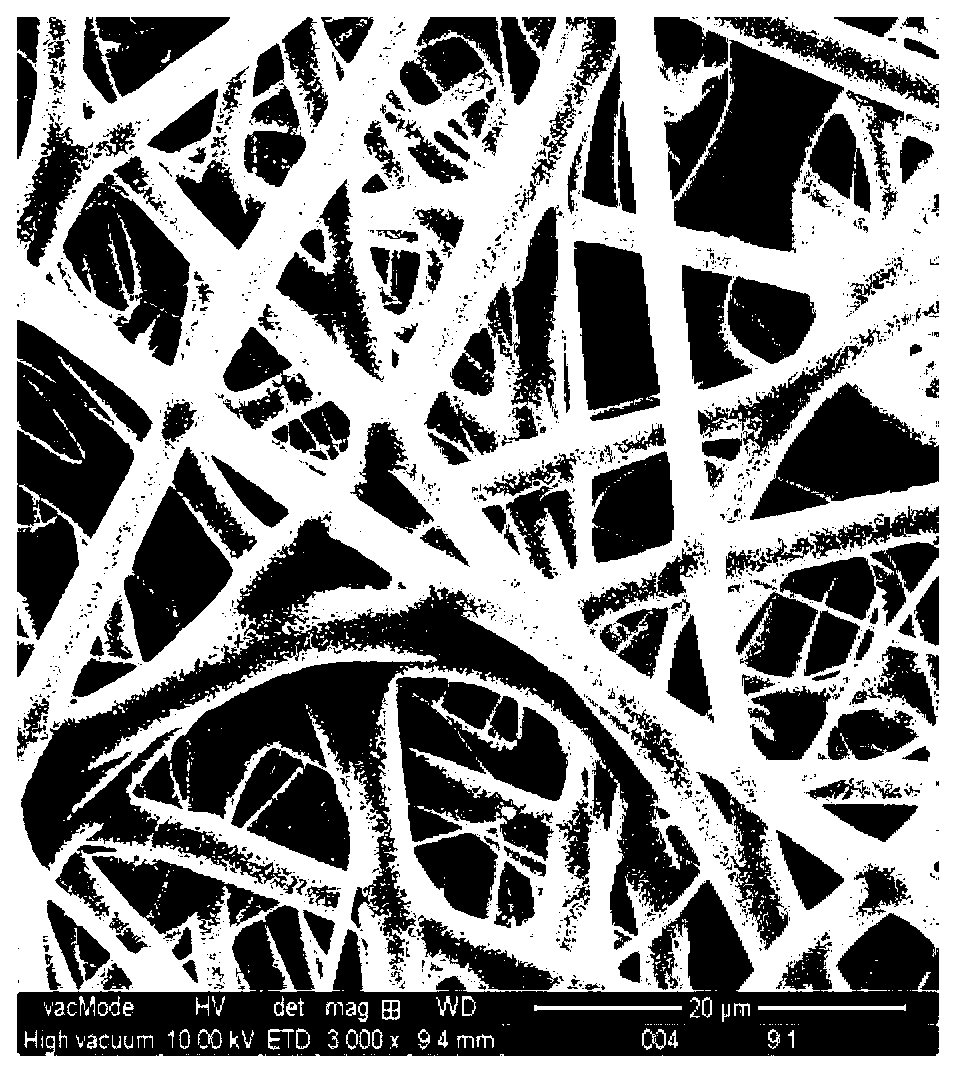

[0021] Weigh 0.4 g of P(LLA-CL) with an electronic analytical balance and dissolve it in 5 ml of hexafluoroisopropanol to obtain a P(LLA-CL) solution with a concentration of 8% (g / ml); weigh it with an electronic analytical balance 0.1 gram of magnesium powder, dissolved in 8% (g / ml) P(LLA-CL) solution, magnetically stirred at room temperature until completely dissolved (the mass ratio of P(LLA-CL) to magnesium powder in the solution is 4:1 ); after dissolving, the solution is an electrospinning solution, the voltage is 14 kV, the advancing speed of the syringe is 1.5 ml / hour, and the receiving distance is 15 cm. The No. 9 needle is selected and accepted by aluminum foil paper to obtain a P( LLA-CL) and metal magnesium powder nano-hybrid fiber membrane.

Embodiment 3

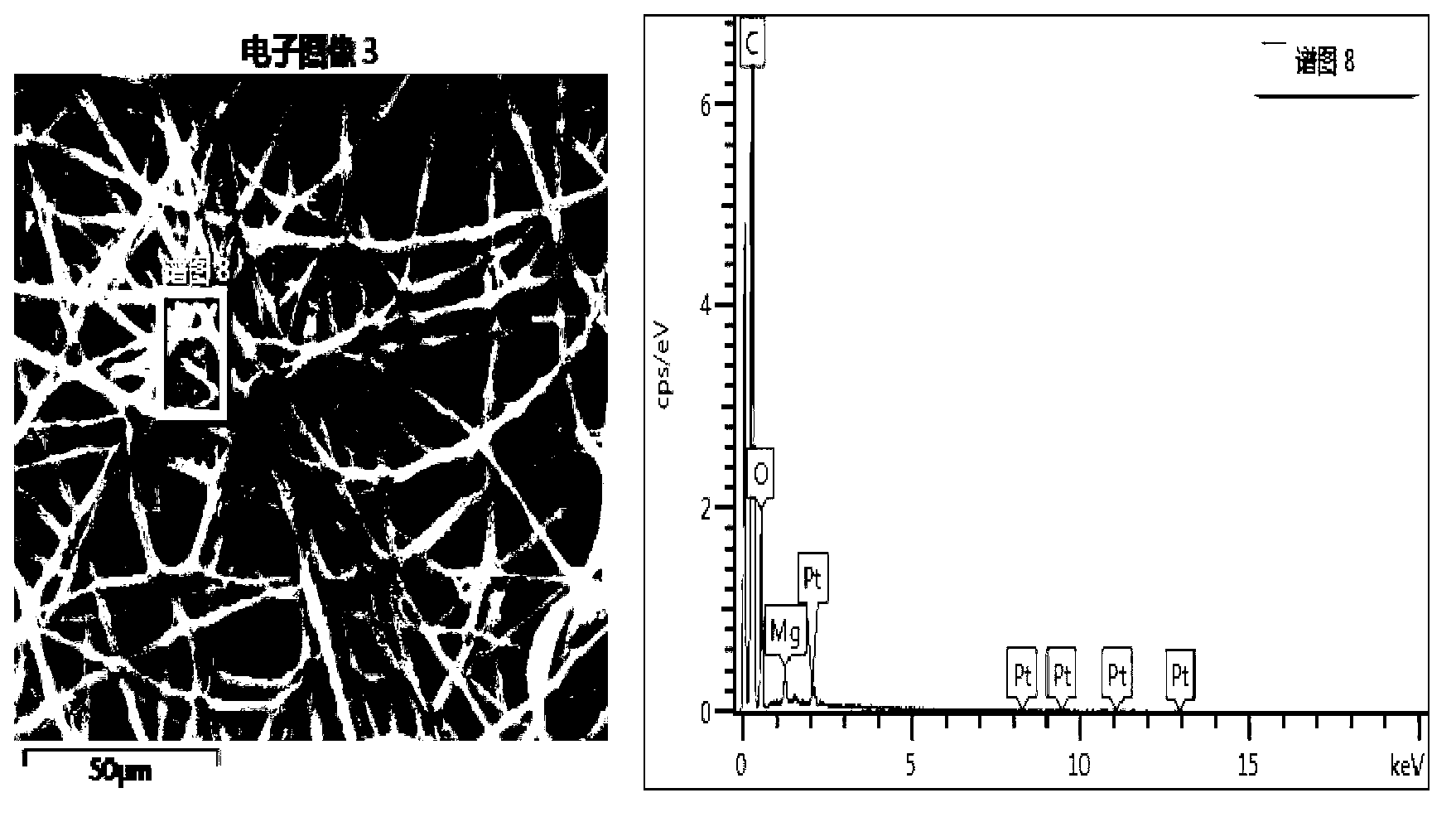

[0023] Weigh 0.4 g of P(LLA-CL) with an electronic analytical balance and dissolve it in 5 ml of hexafluoroisopropanol to obtain a P(LLA-CL) solution with a concentration of 8% (g / ml); weigh it with an electronic analytical balance 0.045 grams of magnesium powder, dissolved in 8% (g / ml) P(LLA-CL) solution, magnetically stirred at room temperature until completely dissolved (the mass ratio of P(LLA-CL) to magnesium powder in the solution is 9:1 ); after dissolving, the solution is an electrospinning solution, the voltage is 20 kV, the advancing speed of the syringe is 0.5 ml / hour, and the receiving distance is 20 cm. The No. 9 needle is selected and accepted by aluminum foil to obtain a P( LLA-CL) and metal magnesium powder nano-hybrid fiber membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com