Fast test device capable of simultaneously measuring air passage eddy and tumble of gasoline engine

A test device, gasoline engine technology, applied in the direction of measurement device, machine/structural component test, internal combustion engine test, etc., can solve the problems of difficult to achieve rapid measurement automation, high work intensity, inconvenient clamping, etc., and achieve consistent repeated test data. High performance, low rotational resistance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and principle of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

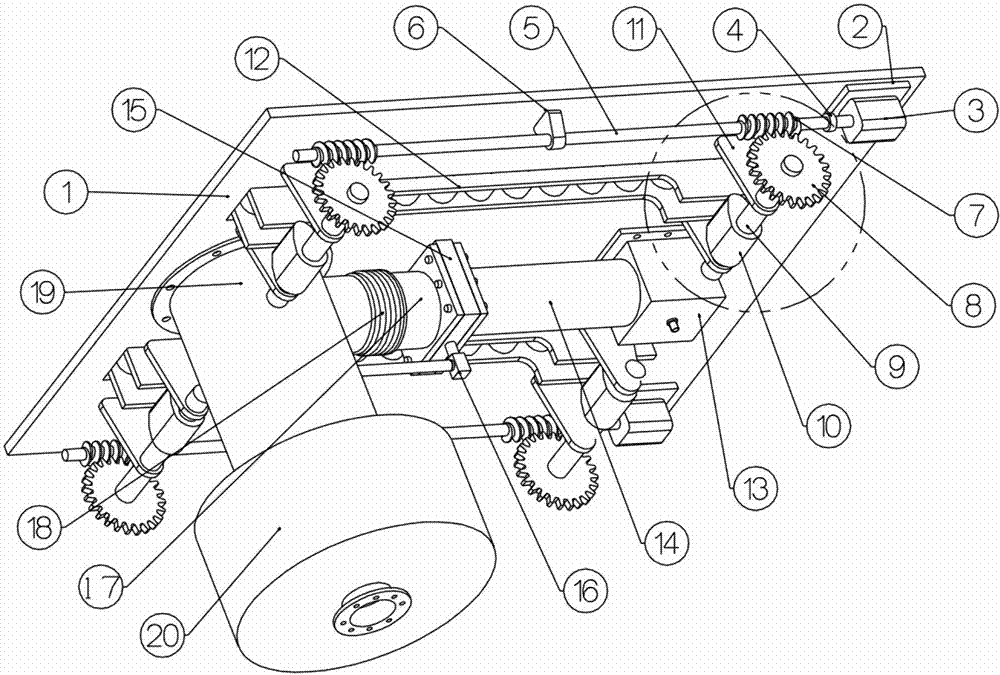

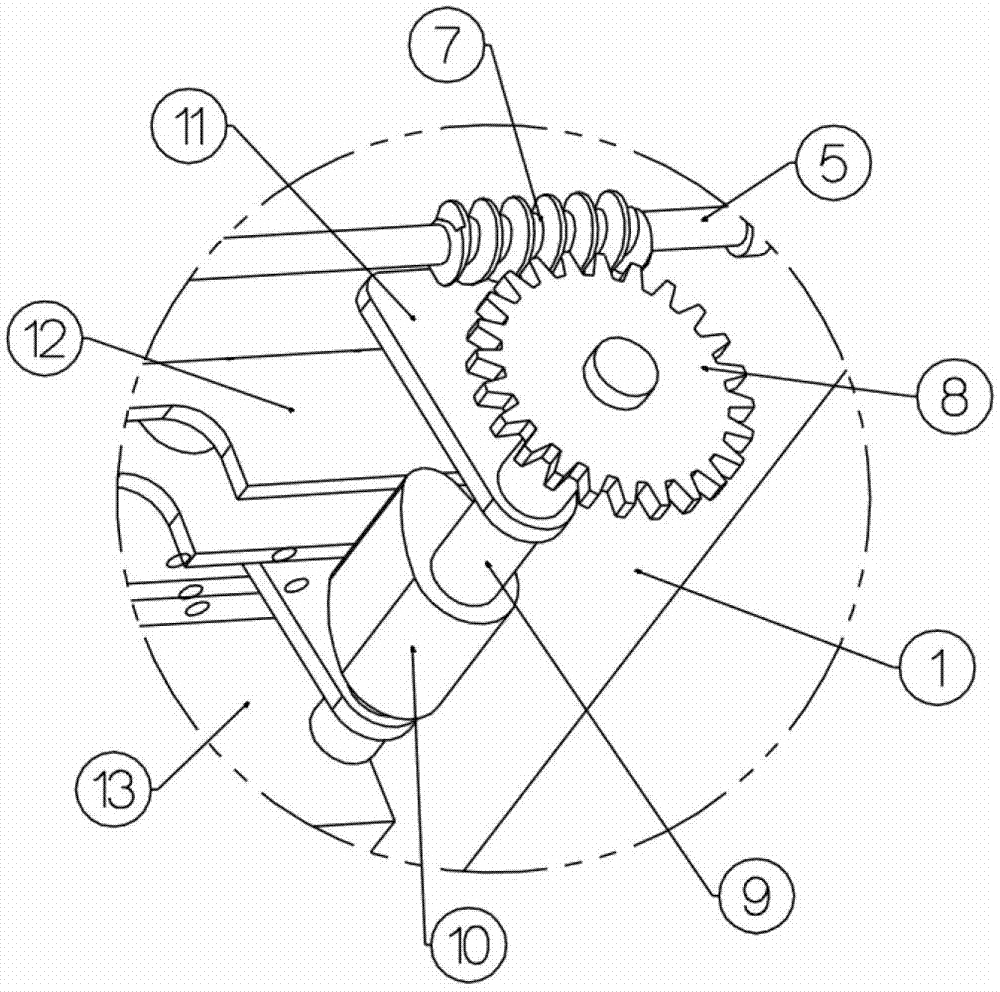

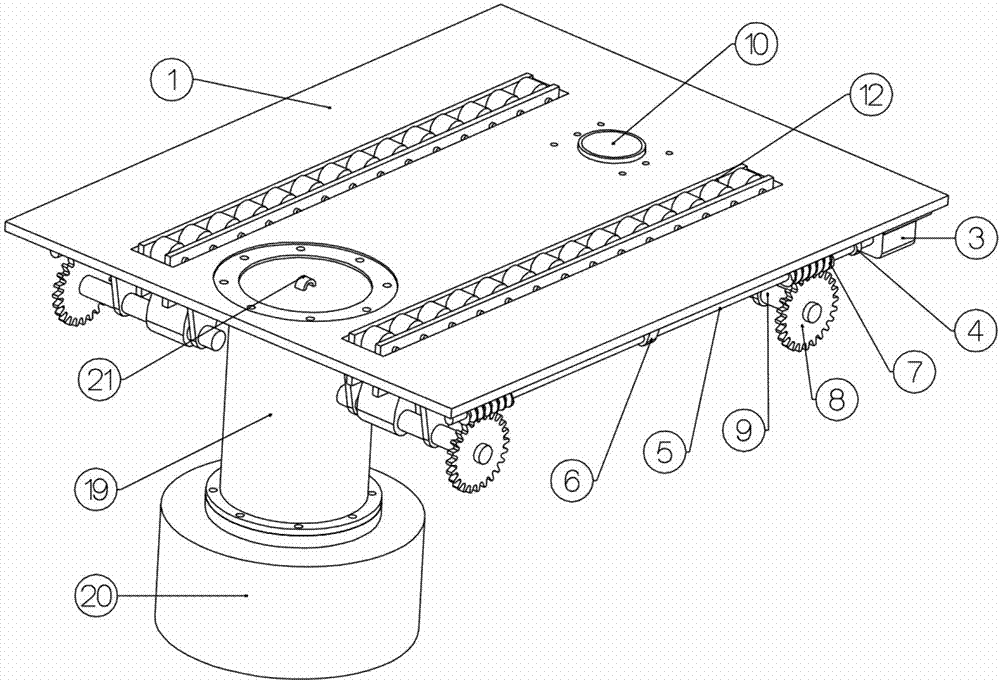

[0025] A rapid test device that can simultaneously measure the vortex and tumble flow in the gas passage of a gasoline engine. The roller table lifting assembly is composed of connecting plate, synchronous motor, coupling, worm shaft, worm shaft bracket, worm, worm gear, camshaft, cam, camshaft bracket and roller table components. The air flow guide assembly is composed of a square box, a guide sleeve, a vane anemometer bracket, a protective tube, a connecting sleeve, a bellows, a transition sleeve, a pressure regulator cylinder, and a sealing disc component. The vane-type anemometer assembly consists of dumbbell-shaped blades, anemometer main shaft, anemometer jacket, upper radial rolling bearing, lower radial rolling bearing, upper bearing cover, upper positioning sleeve, lower bearing cover, Hall sensor sleeve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com