Quick batch test device for light, color and electricity performance of LED

A light-emitting diode and batch testing technology, which is applied in testing optical performance and lamp testing, can solve the problems of unsuitable light-emitting diode LED rapid testing, long time consumption, and low efficiency of optical performance testing, achieving high integration and low efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

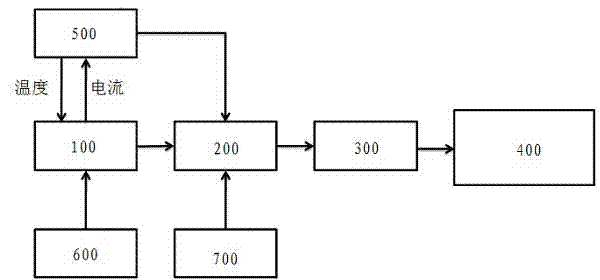

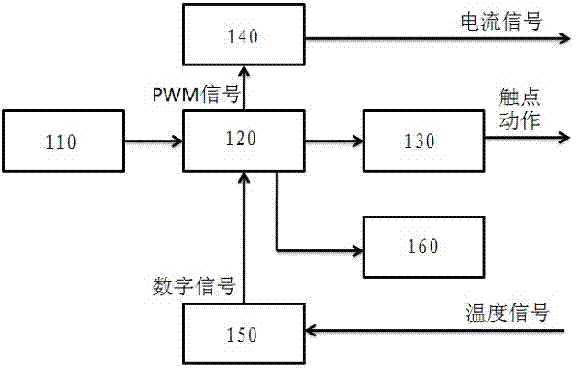

[0021] In this example, see figure 1 , a light-emitting diode LED light, color and electricity performance rapid batch testing device, including a control circuit board 100, an integrating sphere 300, a PC 400, a heating module 500, a constant voltage source module 600 and a constant current source module 700, a constant voltage source module 600 A 350mA constant current source is used to power the drive control circuit board 100, the semiconductor LED device 200 to be tested is powered by the constant current source module 700, the integrating sphere 300 is used to test the optical performance of the semiconductor LED device 200 to be tested, and the test results are transmitted to the PC 400, the integrating sphere 300 adopts the HAAS-2000 integrating sphere of Yuanfang Optoelectronics, the PC 400 processes the data transmitted by the integrating sphere 300 and displays the results, the heating module 500 is connected to the control circuit board 100 for signals, and batches ...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, especially in that:

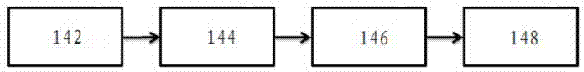

[0026] In this example, see image 3 , the heating drive module 140 is built based on an operational amplifier circuit, which is composed of an integral module 142, a voltage follower module 144, a second-order filter module 146 and a comparison voltage output module 148 in series to form a drive circuit, and the integral module 142 is used to convert the pulse width modulation signal into Sawtooth signal, the voltage following module 144 realizes voltage buffering, the second-order filter module 146 filters out the burrs of the sawtooth signal, and finally the comparison voltage output module 148 compares the sawtooth signal with the reference voltage and outputs the corresponding control signal, and sends the control signal It is added to the gate level of a field effect transistor (MOSFET), so as to realize the adjustment of the output current, and finally control the heating element of the ...

Embodiment 3

[0028] This embodiment is basically the same as the previous embodiment, and the special features are:

[0029] In this embodiment, the heating module 500 adopts a semiconductor heating and cooling chip, and can adopt a semiconductor heating and cooling chip TEC1-12706, which has high cooling efficiency and is easy to realize digital signal control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com