Tinned copper wire for new energy automobile and production process thereof

A technology for new energy vehicles and tinned copper wires, applied in the field of tinned copper wires, can solve the problems of inability to remove the oxide layer of copper wires, low plating rate, pollute the surrounding air and environment, etc., to achieve bright and Activation effect, good permeability and compatibility, effect of improving antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

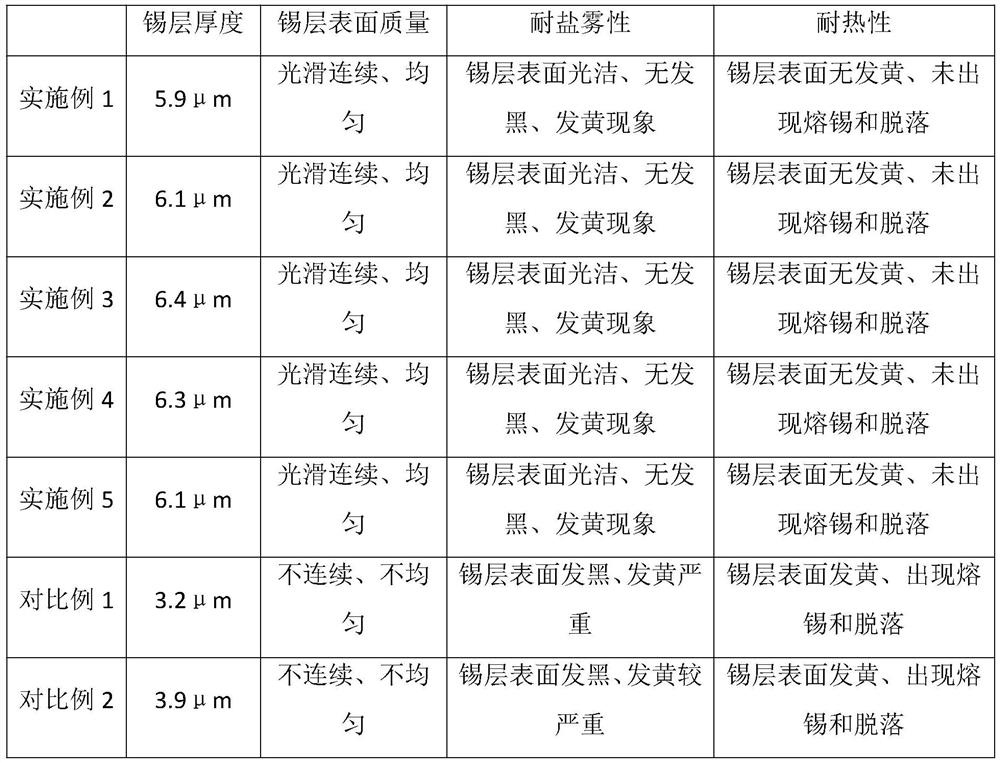

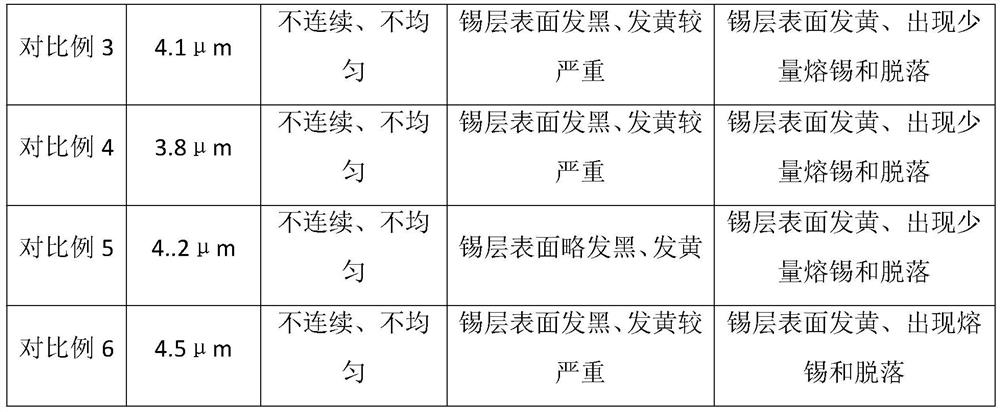

Examples

Embodiment 1

[0025] A production process of tinned copper wire for new energy vehicles, comprising the following steps:

[0026] (1) Pulling the copper rod through heating wire drawing equipment and a wire drawing die, and performing annealing heat treatment during the drawing forming process, so that the copper rod is drawn into a bare copper wire;

[0027] (2) Then put the annealed bare copper wire into the cleaning solution for 9 seconds, wherein the cleaning solution consists of the following raw materials in parts by weight: 8 parts of amino acid chelated calcium, 5 parts of polyaspartic acid, amino 3 parts of trimethylene phosphine, 4 parts of polyethylene glycol oleate, 3 parts of dipropylene glycol butyl ether, 3 parts of coconut oil fatty acid diethanolamide, 6 parts of sodium dibutylnaphthalene sulfonate, 2 parts of sodium o-nitrophenolate 3 parts of oxidized starch, 1 part of nicotinic acid, and 60 parts of water; the preparation method of the cleaning solution includes: dissolv...

Embodiment 2

[0031] A production process of tinned copper wire for new energy vehicles, comprising the following steps:

[0032] (1) Pulling the copper rod through heating wire drawing equipment and a wire drawing die, and performing annealing heat treatment during the drawing forming process, so that the copper rod is drawn into a bare copper wire;

[0033] (2) Then put the annealed bare copper wire into the cleaning solution for 8 seconds, wherein the cleaning solution consists of the following raw materials in parts by weight: 9 parts of amino acid chelated calcium, 6 parts of polyaspartic acid, amino 4 parts of trimethylene phosphine, 5 parts of polyethylene glycol oleate, 4 parts of dipropylene glycol butyl ether, 3.5 parts of coconut oil fatty acid diethanolamide, 7 parts of sodium dibutylnaphthalene sulfonate, 3 parts of sodium o-nitrophenolate 4 parts of oxidized starch, 1.2 parts of niacin, and 70 parts of water. The preparation method of the cleaning solution includes: dissolvin...

Embodiment 3

[0037] A production process of tinned copper wire for new energy vehicles, comprising the following steps:

[0038] (1) Pulling the copper rod through heating wire drawing equipment and a wire drawing die, and performing annealing heat treatment during the drawing forming process, so that the copper rod is drawn into a bare copper wire;

[0039] (2) Then put the annealed bare copper wire into the cleaning solution for 7 seconds, wherein the cleaning solution consists of the following raw materials in parts by weight: 10 parts of amino acid chelated calcium, 7.5 parts of polyaspartic acid, amino 4.5 parts of trimethylene phosphine, 6 parts of polyethylene glycol oleate, 5 parts of dipropylene glycol butyl ether, 4 parts of coconut oil fatty acid diethanolamide, 8 parts of sodium dibutylnaphthalene sulfonate, 4 parts of sodium o-nitrophenolate parts, 4.5 parts of oxidized starch, 1.5 parts of nicotinic acid, and 80 parts of water. The preparation method of the cleaning solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com