Preparation method of potassium chloroplatinite

A technology of potassium chloroplatinite and potassium chloroplatinate, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve the problem of time-consuming reduction of chloroplatinic acid, Reducing agent toxicity, insufficient reaction and other problems, to achieve the effect of increasing the yield, shortening the reaction time, and fully reacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

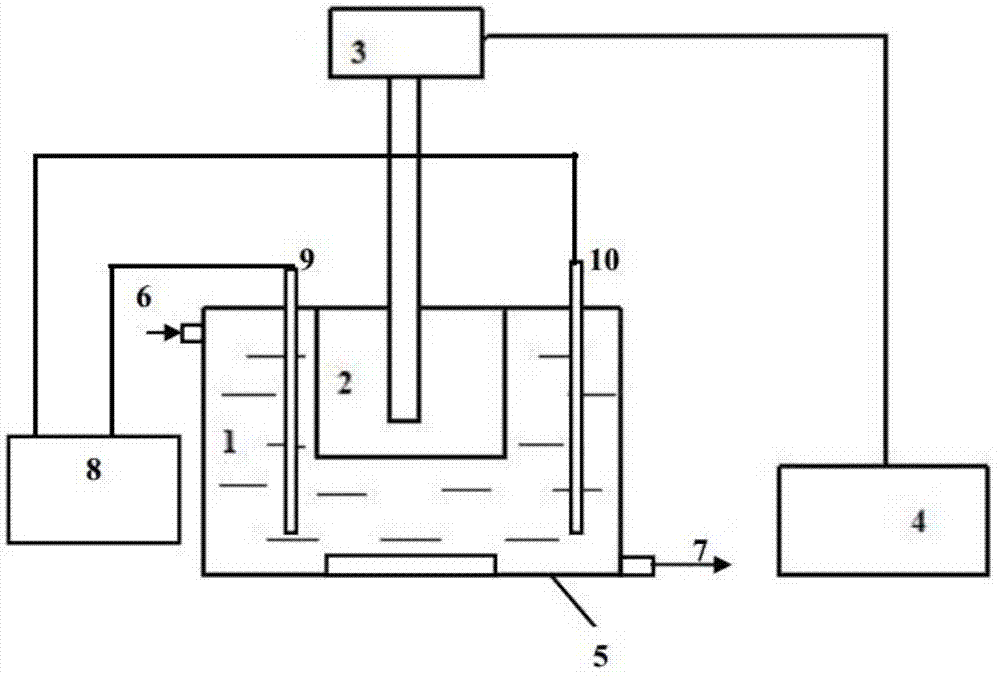

Method used

Image

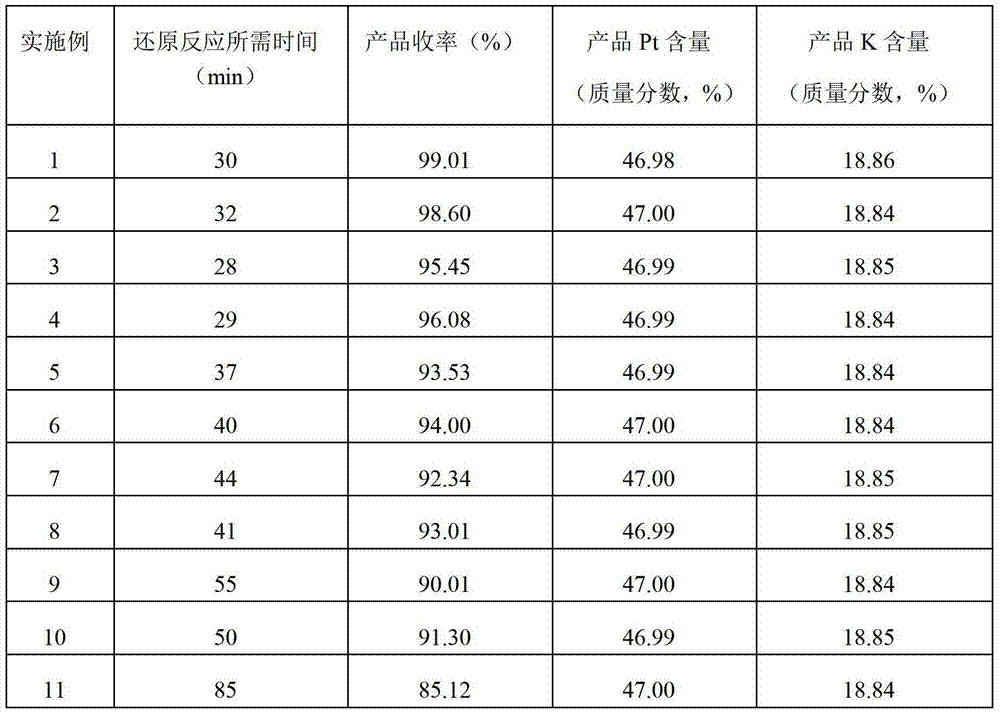

Examples

Embodiment 1

[0038] The method for preparing potassium chloroplatinite described in the present embodiment comprises the steps:

[0039] S01, dissolving 10g of platinum sponge in aqua regia, condensing the solution to a thick syrup through nitrate and acid removal, and then diluting the solution to 100mL to obtain a chloroplatinic acid solution;

[0040] S02, add 100mL10% potassium chloride solution to the chloroplatinic acid solution obtained in the step S01, stir at 60°C until the precipitated precipitate no longer increases, filter to obtain the potassium chloroplatinate precipitate, add 100mL of water to the precipitate, and obtain chlorine Potassium Platinate Suspension;

[0041]S03, at 20-25kHz, 200mW / cm 2 Cosine state ultrasound and 35-40kHz, 200mW / cm 2 Under the condition of co-oscillating with variable-frequency ultrasonic waves, add 435mL of 1% potassium formate solution to the potassium chloroplatinate suspension obtained in the step S02, and stir at 50°C to obtain a scarlet s...

Embodiment 2

[0045] The method for preparing potassium chloroplatinite described in the present embodiment comprises the steps:

[0046] S01, dissolving 10g of platinum sponge in aqua regia, condensing the solution to a thick syrup through nitrate and acid removal, and then diluting the solution to 100mL to obtain a chloroplatinic acid solution;

[0047] S02, add 80mL10% potassium chloride solution to the chloroplatinic acid solution obtained in the step S01, stir at 60°C until the precipitated precipitate no longer increases, filter to obtain the potassium chloroplatinate precipitate, add 100mL of water to the precipitate, and obtain chlorine Potassium Platinate Suspension;

[0048] S03, at 20-25kHz, 200mW / cm 2 Cosine state ultrasound and 35-40kHz, 200mW / cm 2 Under the condition of co-oscillating with variable-frequency ultrasonic waves, add 435mL of 1% potassium formate solution to the potassium chloroplatinate suspension obtained in the step S02, and stir at 50°C to obtain a scarlet s...

Embodiment 3

[0052] The method for preparing potassium chloroplatinite described in the present embodiment comprises the steps:

[0053] S01, dissolving 10g of platinum sponge in aqua regia, condensing the solution to a thick syrup through nitrate and acid removal, and then diluting the solution to 100mL to obtain a chloroplatinic acid solution;

[0054] S02, add 38mL20% potassium chloride solution to the chloroplatinic acid solution obtained in the step S01, stir at 65°C until the precipitated precipitate no longer increases, filter to obtain the potassium chloroplatinate precipitate, add 100mL of water to the precipitate, and obtain chlorine Potassium Platinate Suspension;

[0055] S03, at 20-25kHz, 200mW / cm 2 Cosine state ultrasound and 35-40kHz, 200mW / cm 2 Under the condition of co-oscillating frequency-conversion ultrasonic waves, add 500mL of 1% potassium formate solution to the potassium chloroplatinate suspension obtained in the step S02, and stir at 70°C to obtain a scarlet solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com