Rubber composition of chemically modified chlorinated polyethylene and unsaturated rubber and preparation method thereof

A technology of chlorinated polyethylene and rubber composition, applied in the field of rubber composition, can solve the problems of phase separation, increased mixing difficulty, poor thermodynamic compatibility, poor physical properties, etc., and achieve the promotion of compatibility, distribution The effect of uniform and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of the chlorinated polyethylene of embodiment 1 chemical modification

[0024] The chlorinated polyethylene of described chemical modification can be prepared according to the following method: the organic solvent of 600 weight parts, the chlorinated polyethylene of 60 weight parts are put into reactor (reflux condenser and mechanical stirring paddle are housed), in Stir continuously in a constant temperature heating bath at 50°C until the chlorinated polyethylene powder is uniformly dispersed in the solvent, at which point the chlorinated polyethylene reaches a partially swollen and partially dissolved state in the organic solvent. Then, 2 parts by weight of sodium N,N-diethyldithiocarbamate was dissolved in 50 parts by weight of dimethylformamide, and added dropwise into the reactor within 30 minutes, protected from light and continued to stir and heat for 24 hours. The reaction mixture is poured into 1000 parts by weight of distilled water to precipit...

Embodiment 2

[0026] The formula of each component of the material is: 60 parts of chemically modified chlorinated polyethylene, 50 parts of natural rubber, 3 parts of sulfur and 3 parts of dicumyl peroxide as vulcanizing agent, 50 parts of carbon black as filling and strengthening agent, The plasticizer uses 5 parts of naphthenic oil and 5 parts of dioctyl phthalate, and the stabilizer uses 10 parts of magnesium oxide and 5 parts of lead stearate.

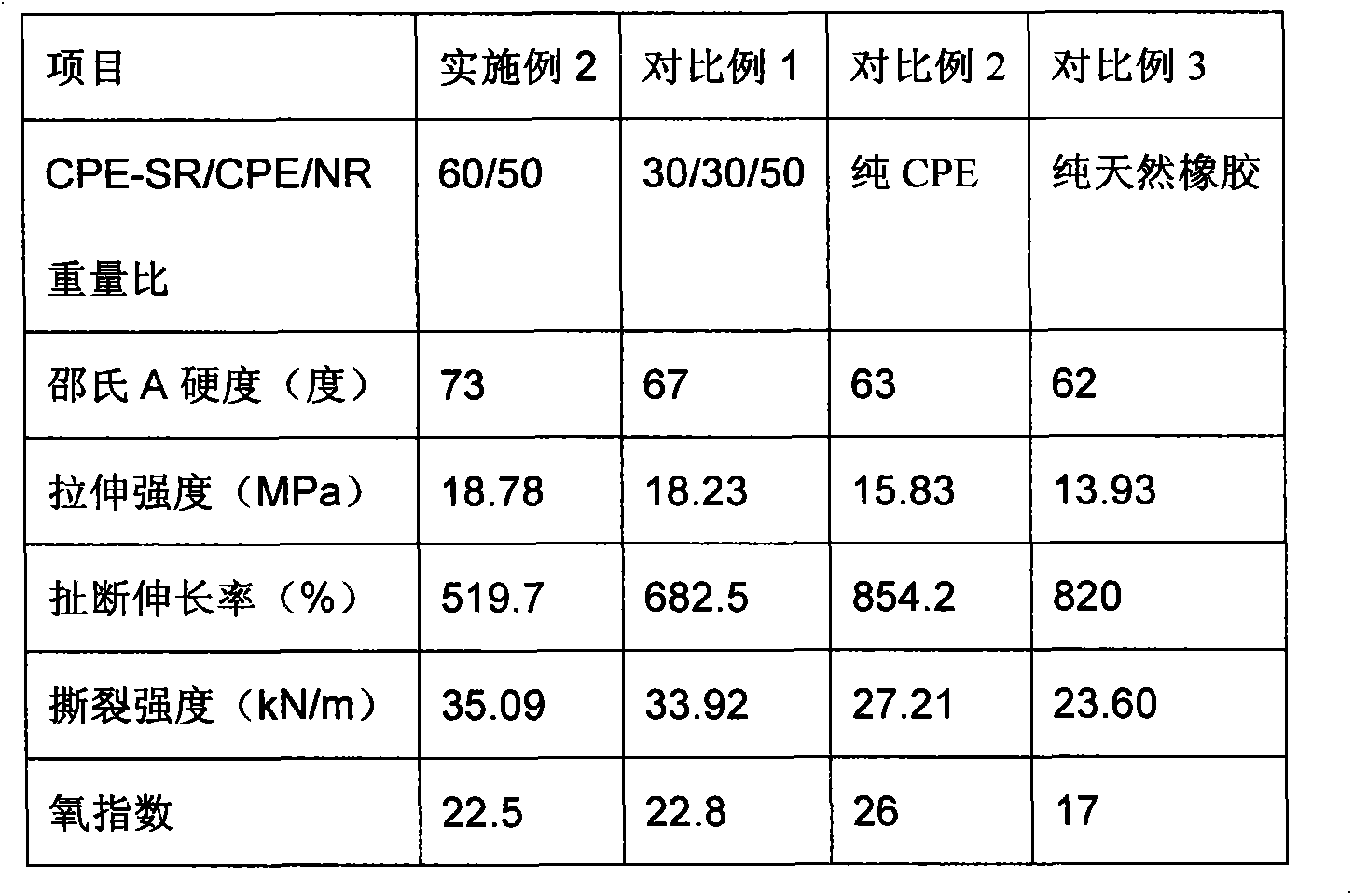

[0027] Preparation method: first mix the weighed chemically modified chlorinated polyethylene and natural rubber in an internal mixer at 90°C for 3 to 4 minutes; then add the weighed filling reinforcing agent and plasticizer in sequence , stabilizer and vulcanizing agent, and then knead for 3 to 5 minutes. When the mixing temperature reaches 100-105 ° C, discharge the mixed rubber from the internal mixer, and then pass the mixed rubber on the open mixer for 2 to 3 minutes. Second-rate. Then vulcanized at 150°C for 25 minutes. The properties o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com