Preparation method of cadmium-free buffer layer in flexible CIGS thin film solar cell

A buffer layer and flexible technology, applied in the field of preparation of cadmium-free buffer layer, can solve the problems that the buffer layer of CIGS solar cells cannot be prepared, and the negative impact of CIGS absorber film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

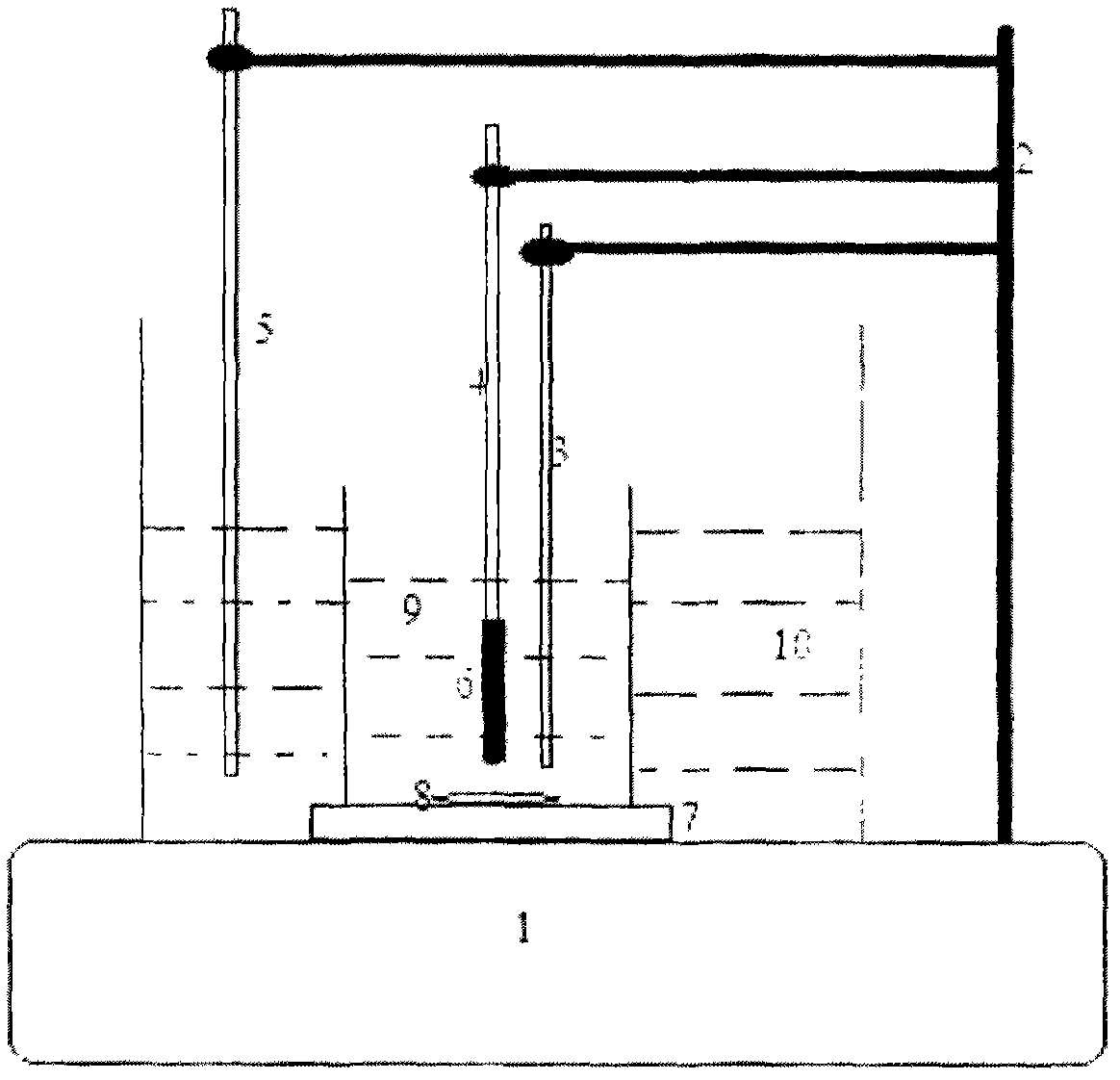

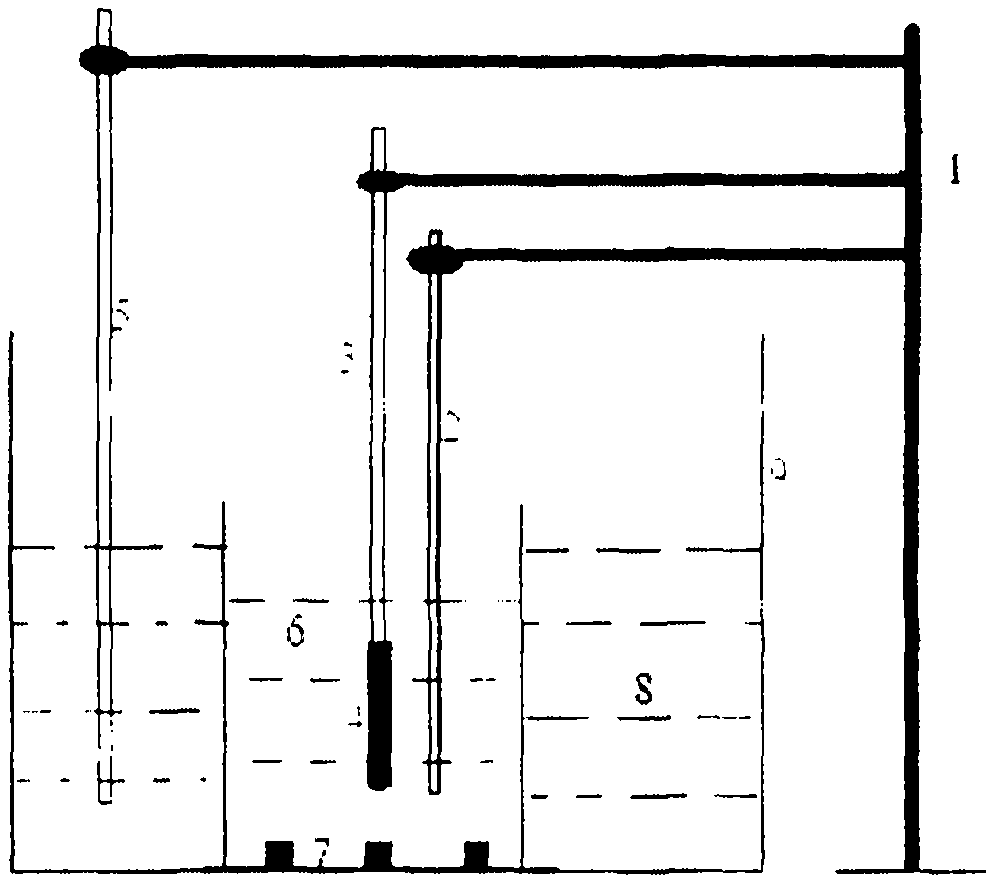

[0017] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

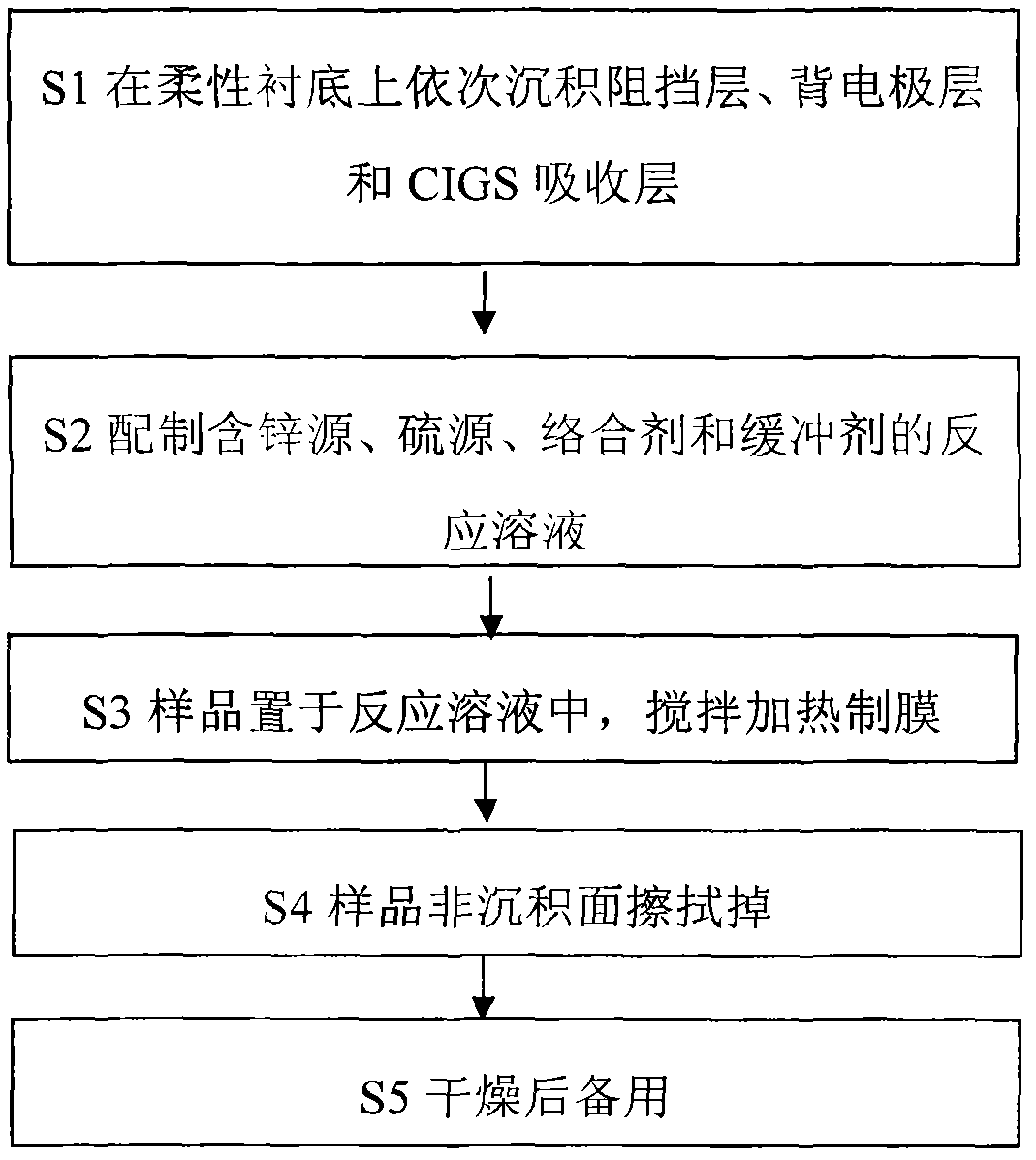

[0018] See attached figure 1 , is a flow chart of the method for preparing a zinc sulfide thin film of the present invention. Such as figure 1 , the preparation of the zinc sulfide buffer layer of the present invention starts from step S1 at first, that is, first depositing a barrier layer, a back electrode layer and a CIGS absorbing layer sequentially on the cleaned stainless steel substrate. Then carry out step S2, prepare the reaction solution that contains zinc source, sulfur source, complexing agent and buffering agent, wherein optimal each substance ratio is: zinc acetate concentration is 0.025mol / L, and thiourea concentration is 0.03mol / L , the complexing agent is sodium citrate 0.02mol / L and tartaric acid 0.018mol / L, and the pH value of the reaction solution is adjusted to 9.5-10.5 with ammonia water. In step S3, the sample is dried in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com