Silicon crystal keel block having nucleation promoting particles and method for manufacturing the same

A particle and silicon crystal technology, applied in the field of silicon crystal ingot and its manufacturing, can solve the problems of polysilicon casting difficulty, increase the control of the initial supercooling degree, and the quality of silicon crystal ingot crystal deterioration, etc., to achieve photoelectric conversion High efficiency, avoiding the effects of incomplete growth and less grain competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

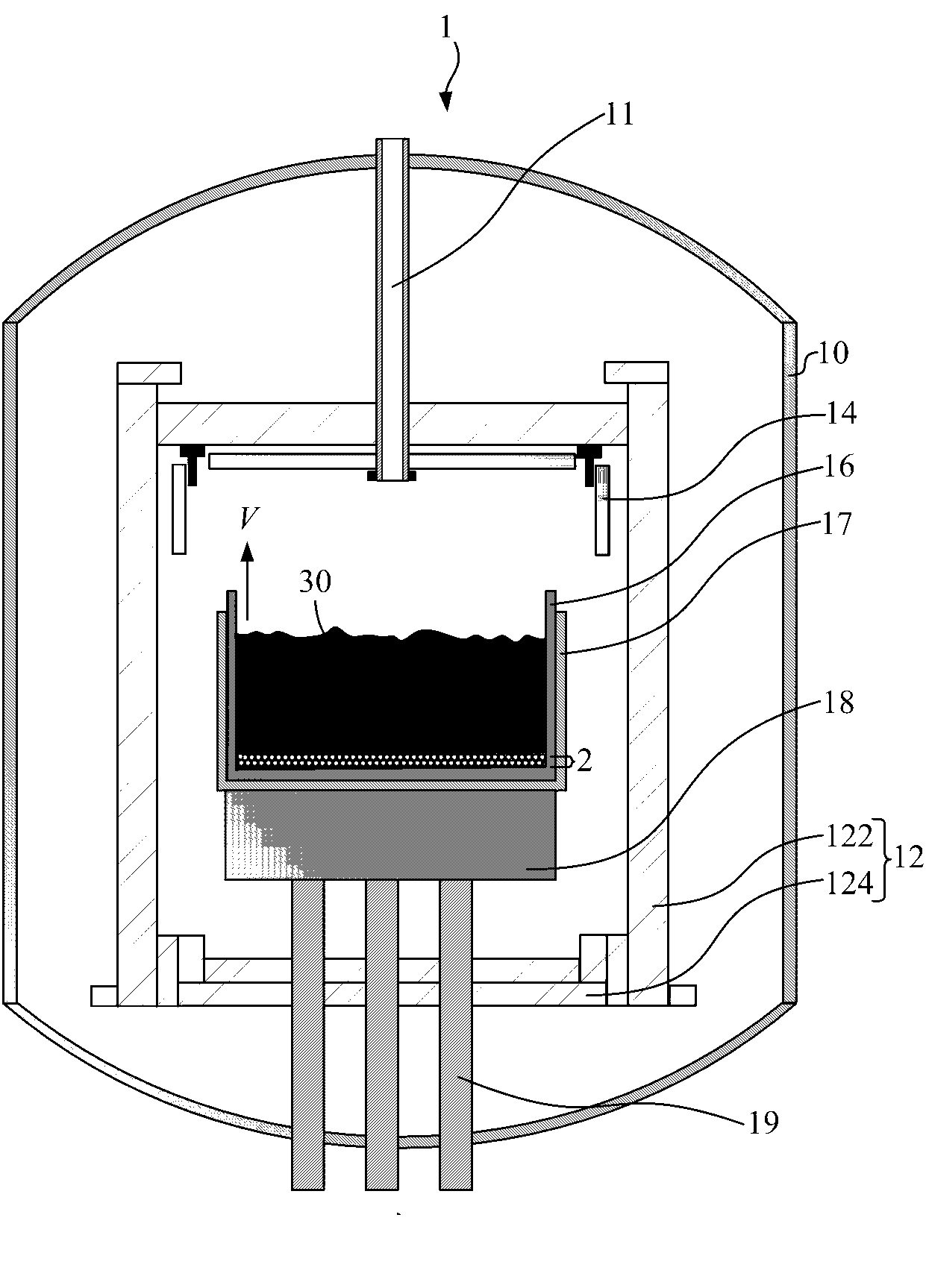

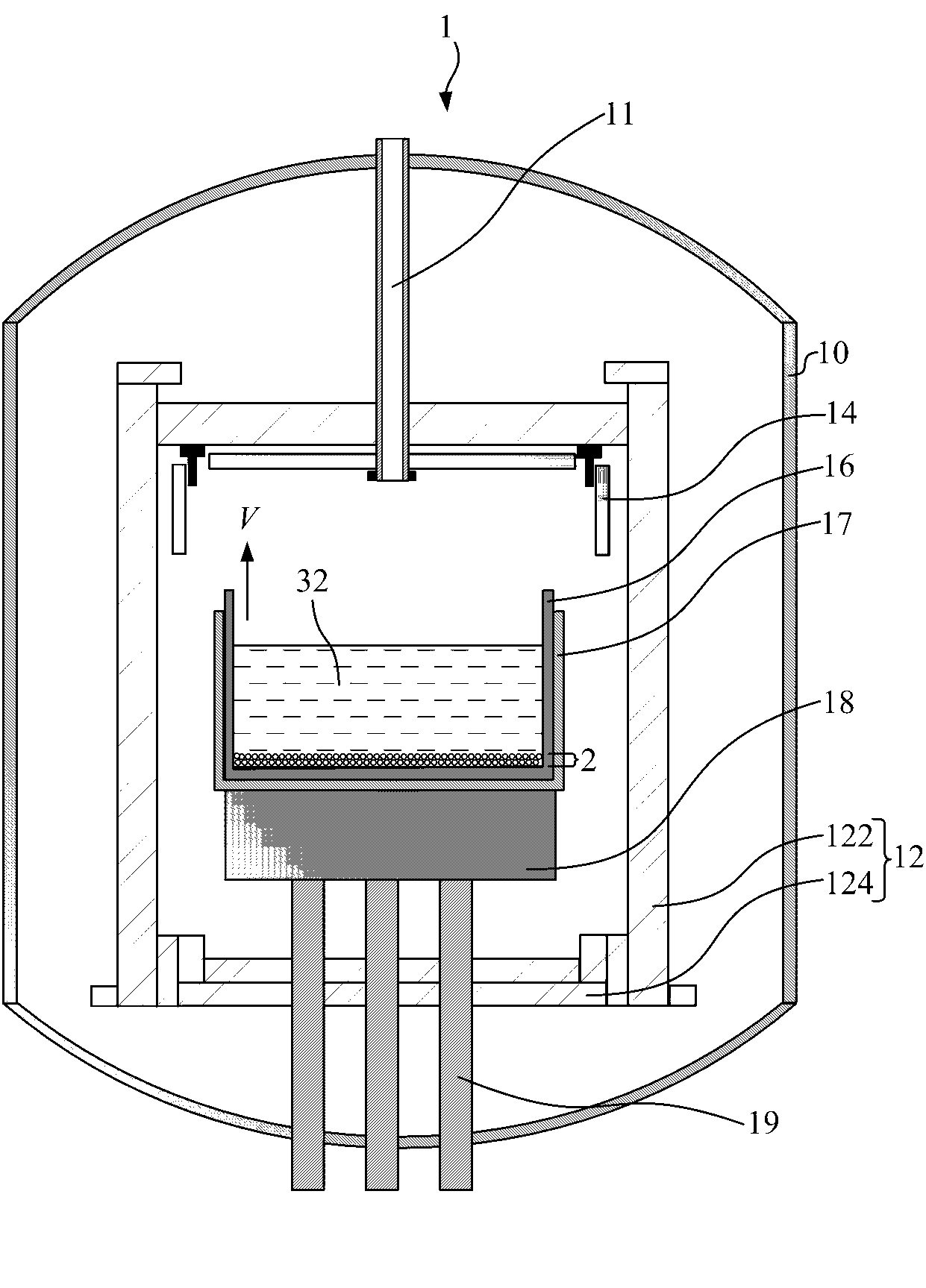

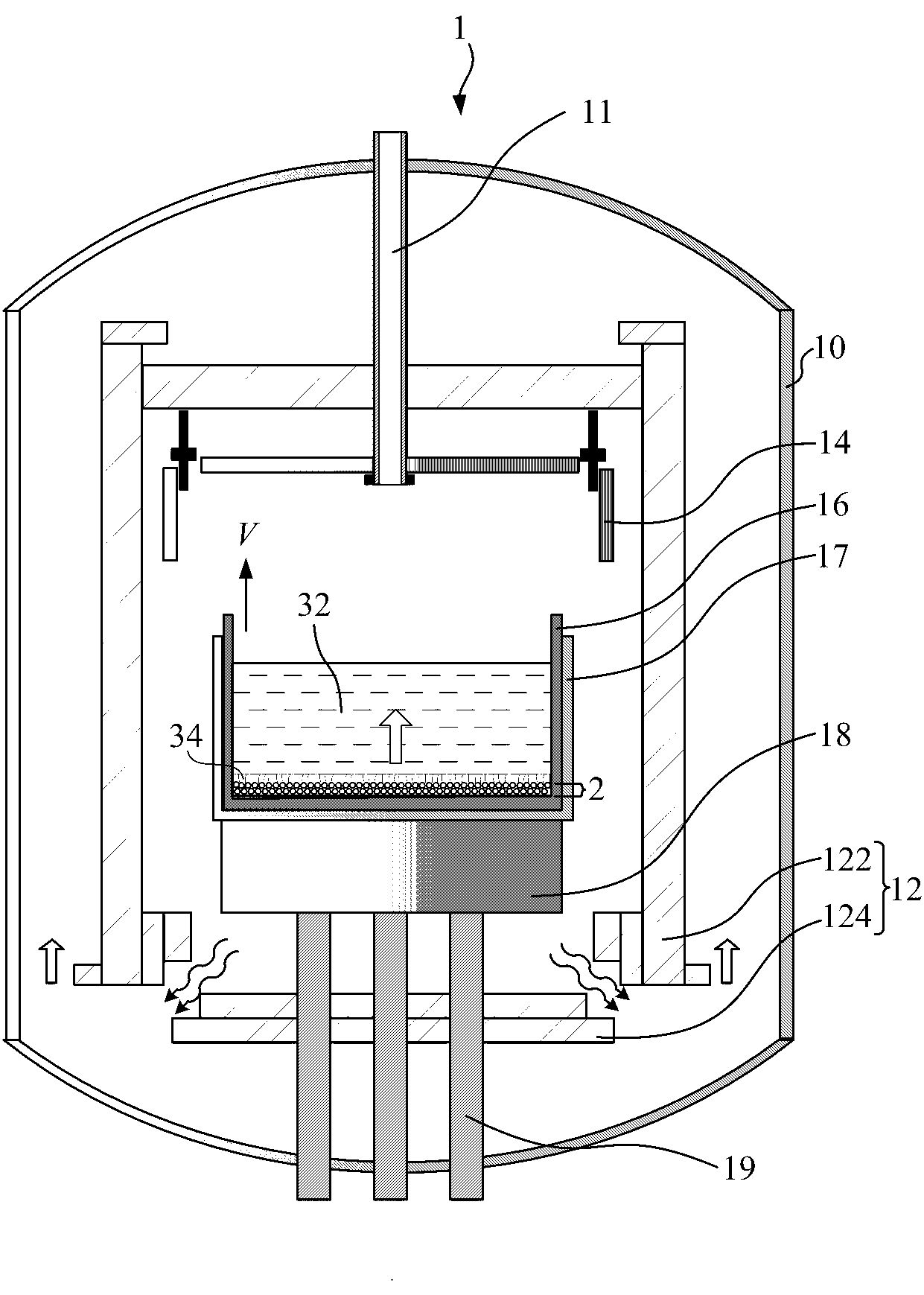

[0026] see Figure 1A~Figure 1D , a schematic cross-sectional view of a preferred embodiment of the method for manufacturing a silicon crystal ingot according to the present invention.

[0027] Such as Figure 1A As shown, the manufacturing method of the present invention generally follows a directional solidification system (DSS), using a DSS crystal growth furnace 1 . The structure of the DSS crystal growth furnace 1 comprises a body of furnace 10, a heat insulation cage 12 made of an upper heat insulation cover 122 and a lower heat insulation plate 124, a directional solidification block 18 arranged in the heat insulation cage 12, and a support directional solidification block 18 At least one support column 19, a pedestal 17 placed on the directional solidified block 18, a mold 16 placed in the pedestal 17, a heater 14 placed above the mold 16, and the furnace body 10 and the insulation cage 12 An inert gas conduit 11.

[0028] In practice, mold 16 may be a quartz crucibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com