Regulating and controlling system of optical glass set

A technology of optical lens and control system, which is applied in the field of optical lens group, can solve problems such as damage to optical elements, operator injury, time-consuming and labor-consuming, etc., and achieve the effects of improving efficiency, high operating efficiency, and good operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

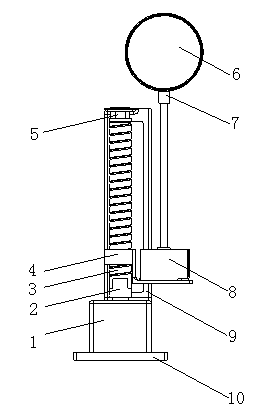

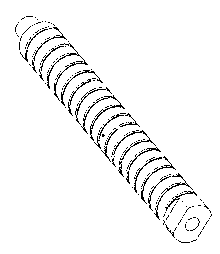

[0027] figure 1 Single optical lens adjustment structure assembly diagram; it mainly consists of stepping motor 1, coupling 2, screw rod 3, stepped nut 4, screw cover 5, optical lens 6, optical lens cover 7, second stepping motor 8. The support frame 9 is composed of a fixed base 10; wherein, the stepping motor 1 is a 17HS5604 motor; the stepping motor 8 is a 28BYJ48 long-axis stepping motor.

[0028] The step angle of the first stepper motor (model 17HS5604) is 1.8° (motor parameters), that is, every time a pulse is given to the 17HS5604 stepper motor, the stepper motor will rotate 1.8°; the motor speed is 60r / min (SCM program control value, variable and adjustable), that is, 1r / s; the lead of the screw is 3mm (every time the screw rotates, that is, 360°, the nut will rise or fall by 3mm); when a pulse is given to the stepping motor, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com