Plasma jet device with suspension electrode

A plasma and jet device technology, applied in the field of plasma, can solve the problem of low density of active particles, and achieve the effects of reducing breakdown voltage, easy ionization, and increasing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

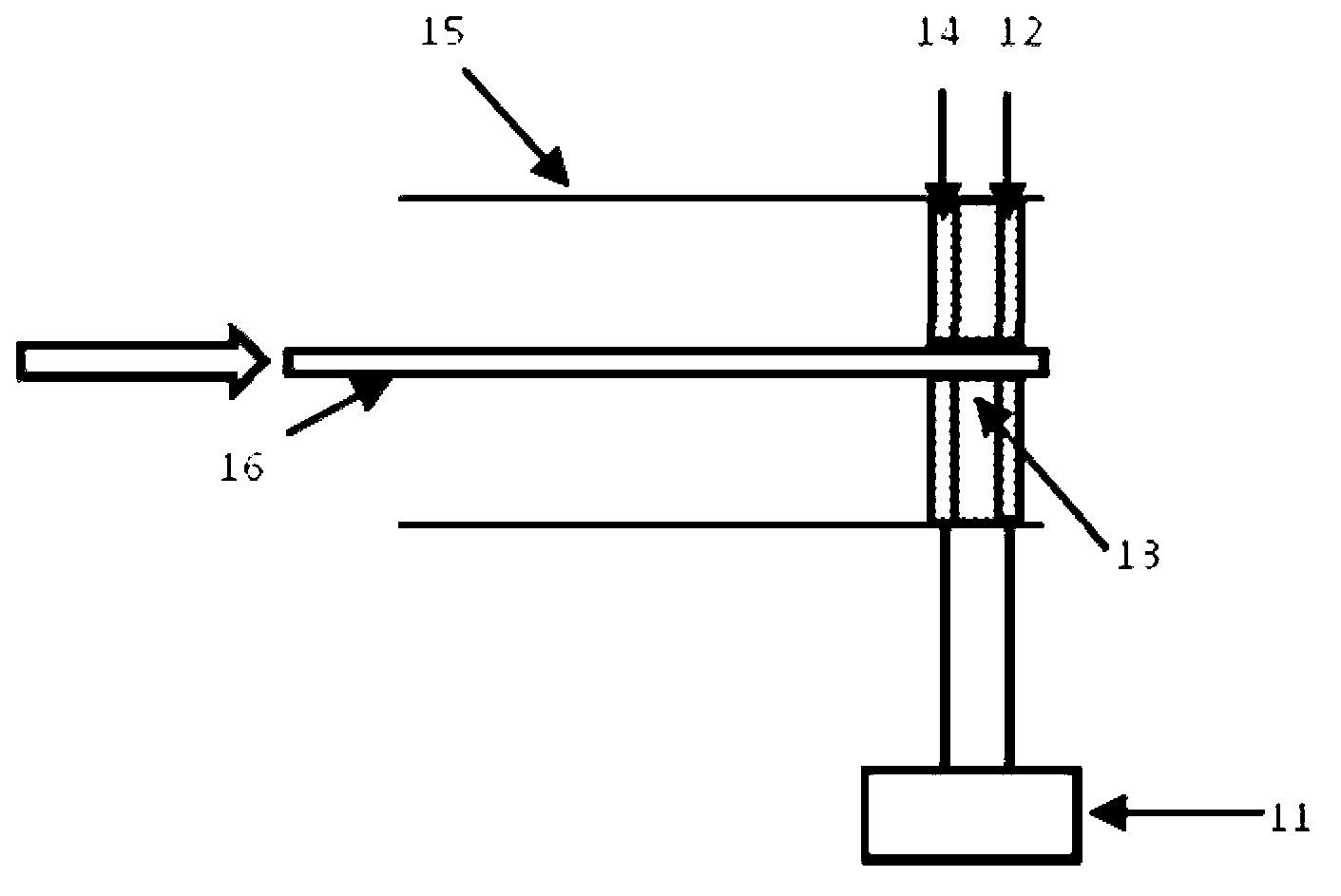

[0038] Embodiment 1: as Figure 4 As shown, the plasma jet device includes a dielectric tube 2, a suspension electrode 1, a high-voltage electrode 3, a vent 10, a working gas 12, and a pressure reducing valve 11. The dielectric tube 2 is a quartz tube or a glass tube with openings at both ends, with an inner diameter of 8 The suspension electrode 1 is a stainless steel needle, and the high-voltage electrode 3 is closely attached to the outer wall of the medium tube. The power supply 6 is a pulse power supply, and the power supply 6 is connected to the high-voltage electrode 3. The working gas 12 enters from the vent 10 through the pressure reducing valve 11, flows out through the medium pipe 2, and generates plasma 4 on the other side of the medium pipe. The working gas can be simple gas such as helium, argon, nitrogen, oxygen, or a mixed gas mixed with other gases, or it can be air, gaseous compounds, or gaseous organic compounds.

[0039] Existing plasma jet devices current...

Embodiment 2

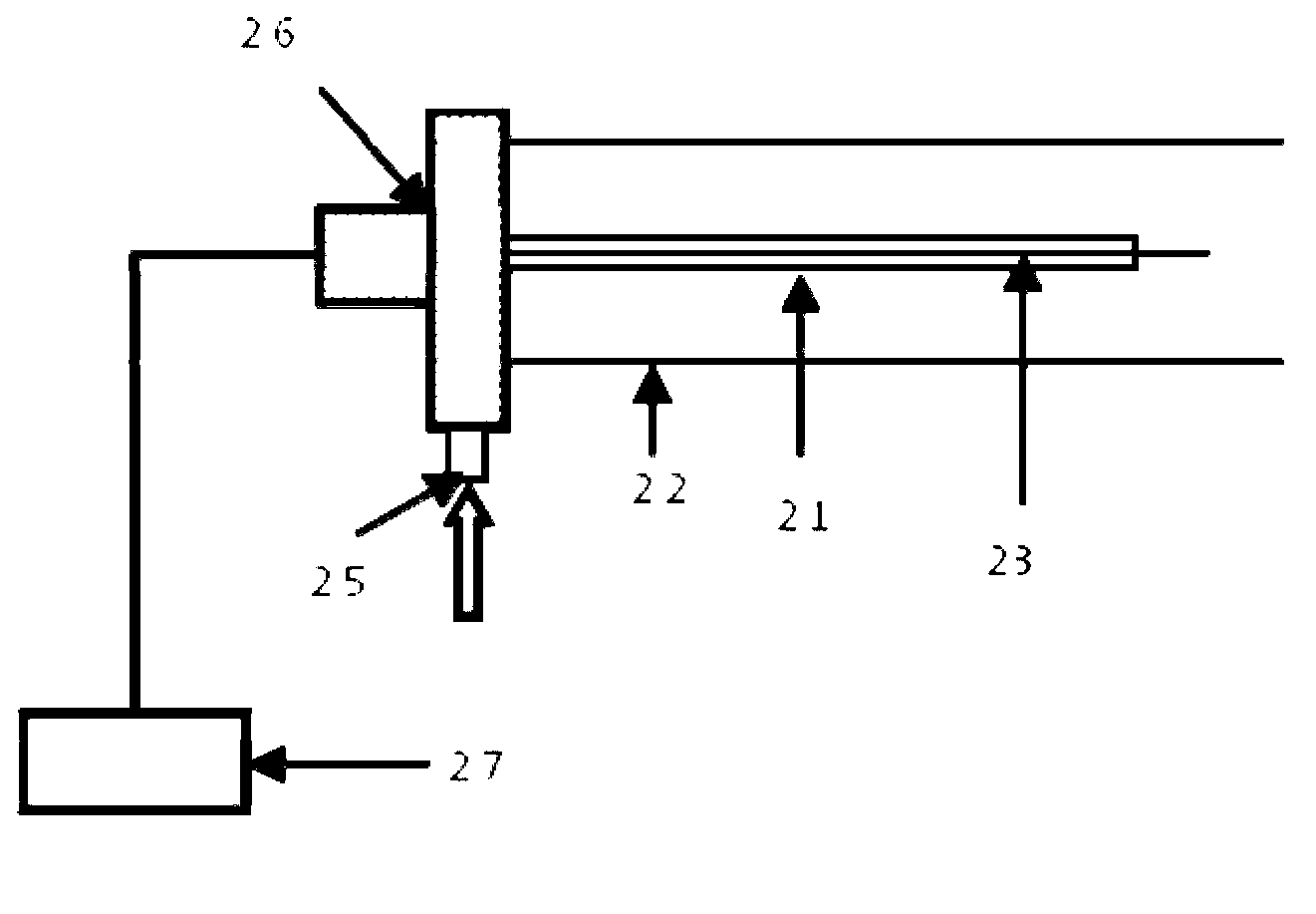

[0040]Embodiment 2: as Figure 5 As shown, the parameters of the dielectric tube 2, the high-voltage electrode 3, and the pulse power supply 6 are the same as those in Example 1. The suspension electrode unit 1 is composed of a suspension electrode and a glass tube sealed at one end. The suspension electrode is a copper wire and is located in the glass tube; the suspension electrode unit uses With the above structure, the insulating medium is inserted into the discharge space to form a dielectric barrier discharge. This suspension electrode device not only has the advantages of Embodiment 1, but also can increase the cross-sectional area of the plasma, thereby increasing the processing capacity in material processing and biomedical applications. area. Due to the use of glass or ceramics as the dielectric barrier discharge, the temperature of the plasma is low, generally room temperature or slightly higher than room temperature.

[0041] Taking helium as an example, the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com