Organic-inorganic hybrid paint composition

A composition and inorganic technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of low crosslinking density, can not meet the adhesion, abrasion resistance, gloss performance, scratches, etc., to improve crosslinking The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0059] —Preparation of Organic Resin 1

[0060] 40 parts by weight of an organic solvent obtained by mixing toluene and n-butyl acetate at a weight ratio of 10:30 was introduced into the reaction flask, and then the reaction mixture was heated to a temperature of about 120°C. Then, in this reaction flask, the monomer comprising 18 parts by weight of methyl methacrylate, 12 parts by weight of butyl acrylate, 16 parts by weight of 2-hydroxyl methacrylate, 7 parts by weight of methacrylic acid and 7 parts by weight of methacrylic acid were gradually added dropwise. Part organic peroxide initiator—benzoyl peroxide, so as to obtain an acrylic resin with a solid content of 60% by weight and a viscosity of 1900cps (weight average molecular weight: 18,000) based on the total weight of the acrylic resin.

[0061] 48 parts by weight of the obtained acrylic resin were introduced together with 20 parts by weight of melamine resin (CYMEL 325 from CYTEC Industries Inc.) and 10 parts by weig...

preparation Embodiment 3

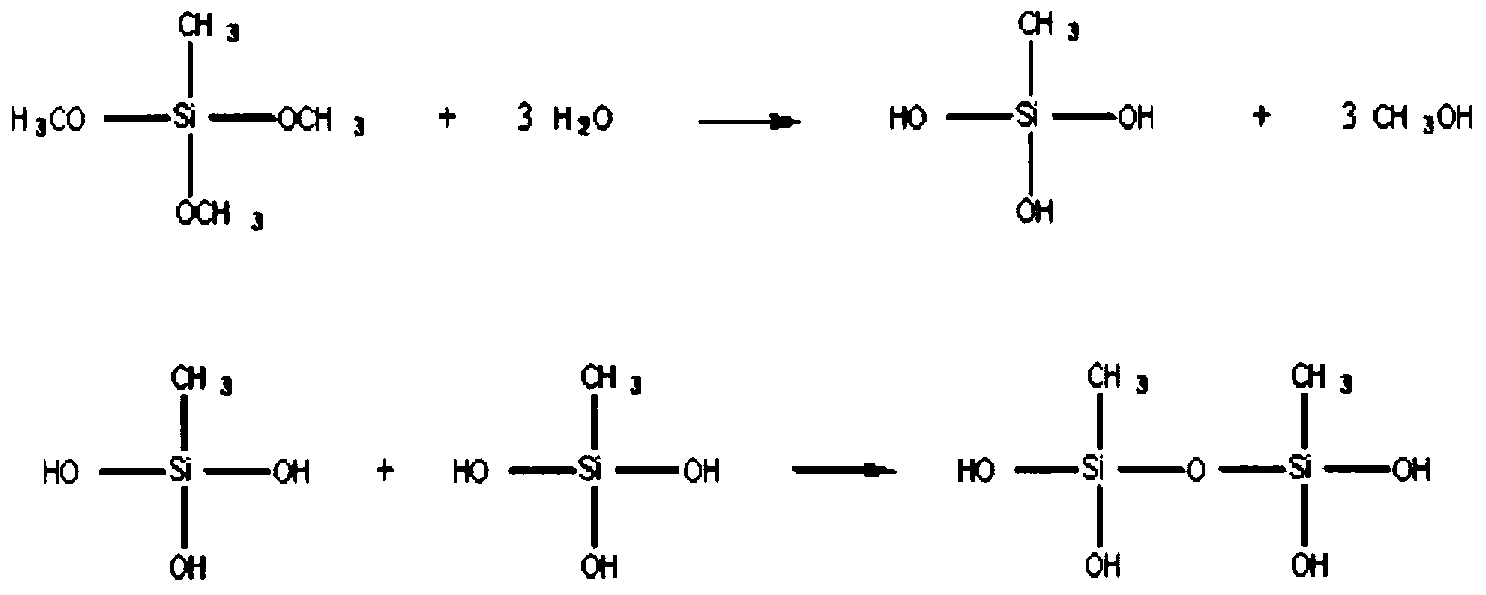

[0065] —Preparation of Inorganic Resin 1

[0066] Add 1 part by weight of acetic acid to 30 parts by weight of colloidal silica (SN-SOL of Japan Catalysts & Chemicals Industries Co. Ltd.) to adjust the pH to about 2-3, and then ) to which was gradually added 50 parts by weight of methyltrimethoxysilane and 19 parts by weight of isopropanol while performing hydrolysis and condensation, thereby obtaining a ceramic resin with a solid content of 40% by weight based on the total weight of the ceramic resin.

preparation Embodiment 4

[0067] —Preparation of Inorganic Resin 2

[0068] Add 1 part by weight of acetic acid to 30 parts by weight of colloidal silica (SN-SOL of Japan Catalysts & Chemicals Industries Co. Ltd.) to adjust the pH to about 2-3, and then ) to which 45 parts by weight of methyltrimethoxysilane, 10 parts by weight of tetraethoxysilane and 14 parts by weight of isopropanol are gradually added to carry out hydrolysis and condensation, thereby obtaining a solid content of 45 based on the total weight of the ceramic resin % by weight ceramic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com