Preparation method of Pt-PbTiO3 nano-catalyst for CO catalytic oxidation

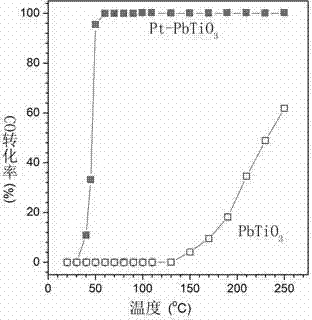

A nano-catalyst and catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It is difficult to control problems such as high catalytic oxidation efficiency, high catalytic activity at low temperature, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

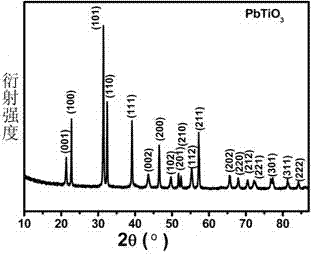

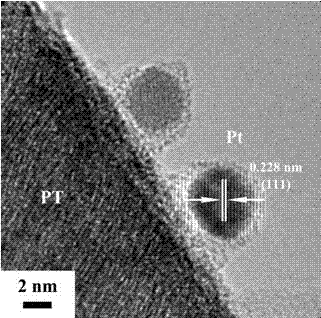

[0017] 1) 0.5 g perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanoparticles into 50ml deionized water, and ultrasonically disperse for 15 minutes to obtain water-dispersed PbTiO 3 suspension;

[0018] 2) In the state of ultrasonic dispersion, disperse PbTiO into the water prepared in step 1) 3 Add 2ml of 50mmol / L H 2 PtCl 6 6H 2 O solution, ultrasonically dispersed for 15 minutes to obtain an ion suspension of lead, titanium and platinum;

[0019] 3) In the state of ultrasonic dispersion, slowly add 60ml of NaBH with a concentration of 0.2 mol / L to the ion suspension of lead, titanium and platinum prepared in step 2) 4 Solution, ultrasonically dispersed for 10min to obtain amorphous Pt-PbTiO 3 Nanoparticle suspension;

[0020] 4) The amorphous Pt-PbTiO obtained in step 3) 3 The nanoparticle suspension was centrifuged to obtain a black precipitate, which was washed with deionized water and ethanol successively until the eluate was neutral,...

Embodiment 2

[0022] 1) 1 g of perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanoparticles into 100ml deionized water, and ultrasonically disperse for 15 minutes to obtain water-dispersed PbTiO 3 suspension;

[0023] 2) In the state of ultrasonic dispersion, disperse PbTiO into the water prepared in step 1) 3 Add dropwise 5ml of H2O with a concentration of 60mmol / L to the suspension 2 PtCl 6 6H 2 O solution, ultrasonically dispersed for 15 minutes to obtain an ion suspension of lead, titanium and platinum;

[0024] 3) In the state of ultrasonic dispersion, slowly add 60ml of NaBH with a concentration of 0.3 mol / L to the ion suspension of lead, titanium and platinum prepared in step 2) 4 Solution, ultrasonically dispersed for 10min to obtain amorphous Pt-PbTiO 3 Nanoparticle suspension;

[0025] 4) The amorphous Pt-PbTiO obtained in step 3) 3 The nanoparticle suspension was centrifuged to obtain a black precipitate, which was washed with deionized water...

Embodiment 3

[0027] 1) 1.5 g perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanoparticles into 200ml deionized water, and ultrasonically disperse for 15 minutes to obtain water-dispersed PbTiO 3 suspension;

[0028] 2) In the state of ultrasonic dispersion, disperse PbTiO into the water prepared in step 1) 3 Add dropwise 6ml of H2O with a concentration of 70mmol / L to the suspension 2 PtCl 6 6H 2 O solution, ultrasonically disperse for 20 minutes to obtain an ion suspension of lead, titanium and platinum;

[0029] 3) In the state of ultrasonic dispersion, slowly add 60ml of NaBH with a concentration of 0.4 mol / L to the ion suspension of lead, titanium and platinum prepared in step 2) 4 Solution, ultrasonically dispersed for 10min to obtain amorphous Pt-PbTiO 3 Nanoparticle suspension;

[0030] 4) The amorphous Pt-PbTiO obtained in step 3) 3 The nanoparticle suspension was centrifuged to obtain a black precipitate, which was washed with deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com