Three-layer co-extruded oxygen absorbing thin film for food package and preparation method thereof

A three-layer co-extrusion and food packaging technology, which is applied in the field of packaging materials, can solve the problems of prolonging the shelf life and storage life of food, high cost, and low cost, and achieve the effect of large oxygen absorption capacity and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

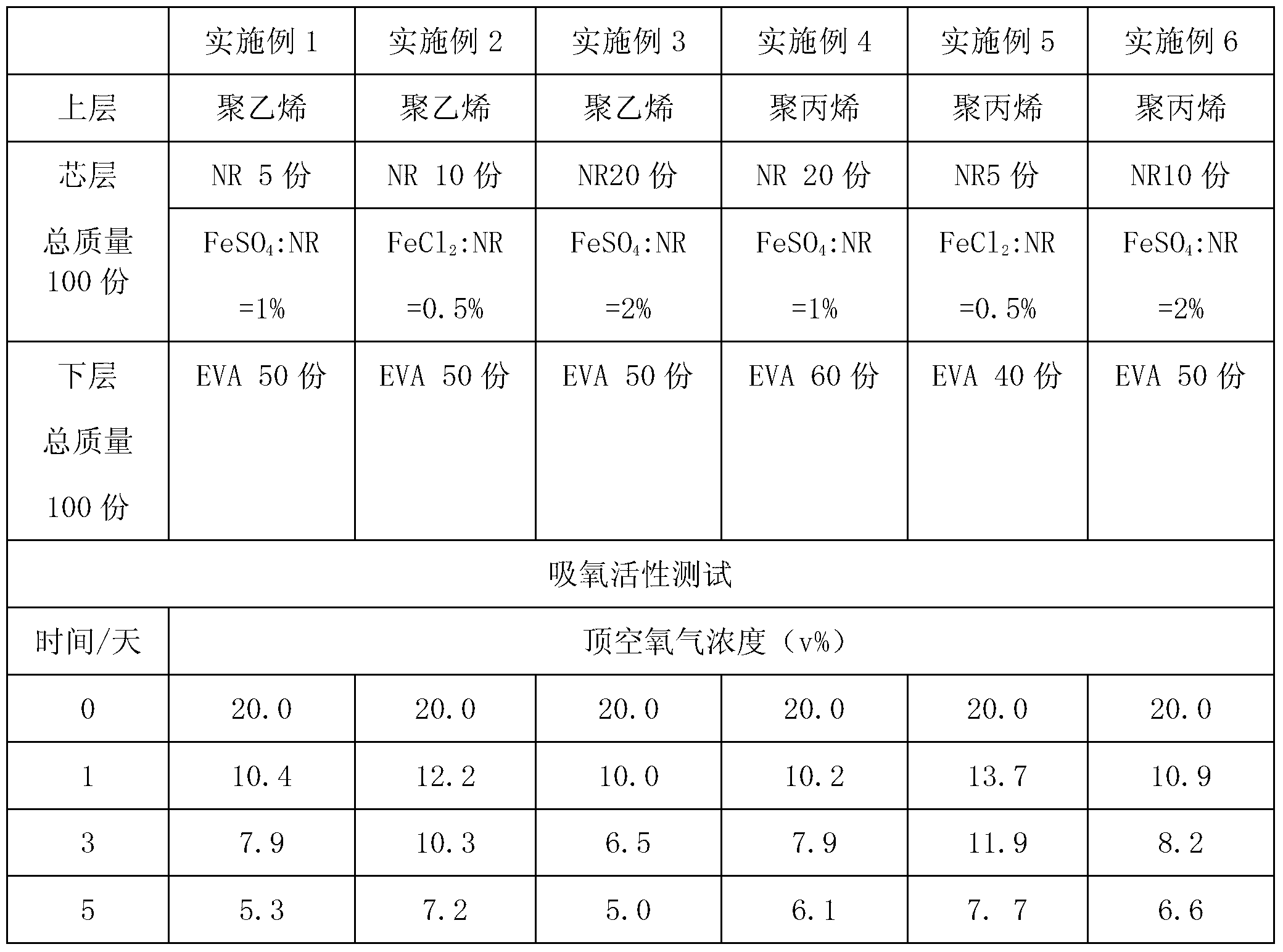

[0026] The present invention will be further described through the following specific embodiments and application examples. The following specific descriptions are for the convenience of understanding the present invention, and are not intended to limit the protection scope of the present invention.

[0027] 1 raw material

[0028] Commodity KOPP film; LD100AC type LDPE resin; F280 type polypropylene resin; 18-0.3 type EVA resin; food grade ferrous sulfate; food grade ferrous chloride.

[0029] 1 Preparation of lower layer (food contact layer) modified resin

[0030] The resin composition of the lower layer (food contact layer) of the three-layer co-extruded oxygen-absorbing film is shown in Table 1; EVA and polyethylene (or polypropylene) resins are mechanically mixed, and then extruded at 145-180°C (polyethylene) on a twin-screw On-machine melt blending to prepare modified polyethylene or polypropylene film. The processing temperature for polypropylene resin is 170-210°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com